Automatic transmission device for electric vehicle

A technology of automatic transmission device and electric vehicle, applied in the field of automobile transmission, can solve the problems of high manufacturing difficulty, high use cost, complex hydraulic control structure, etc., and achieve the effects of compact structure, high power transmission efficiency and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

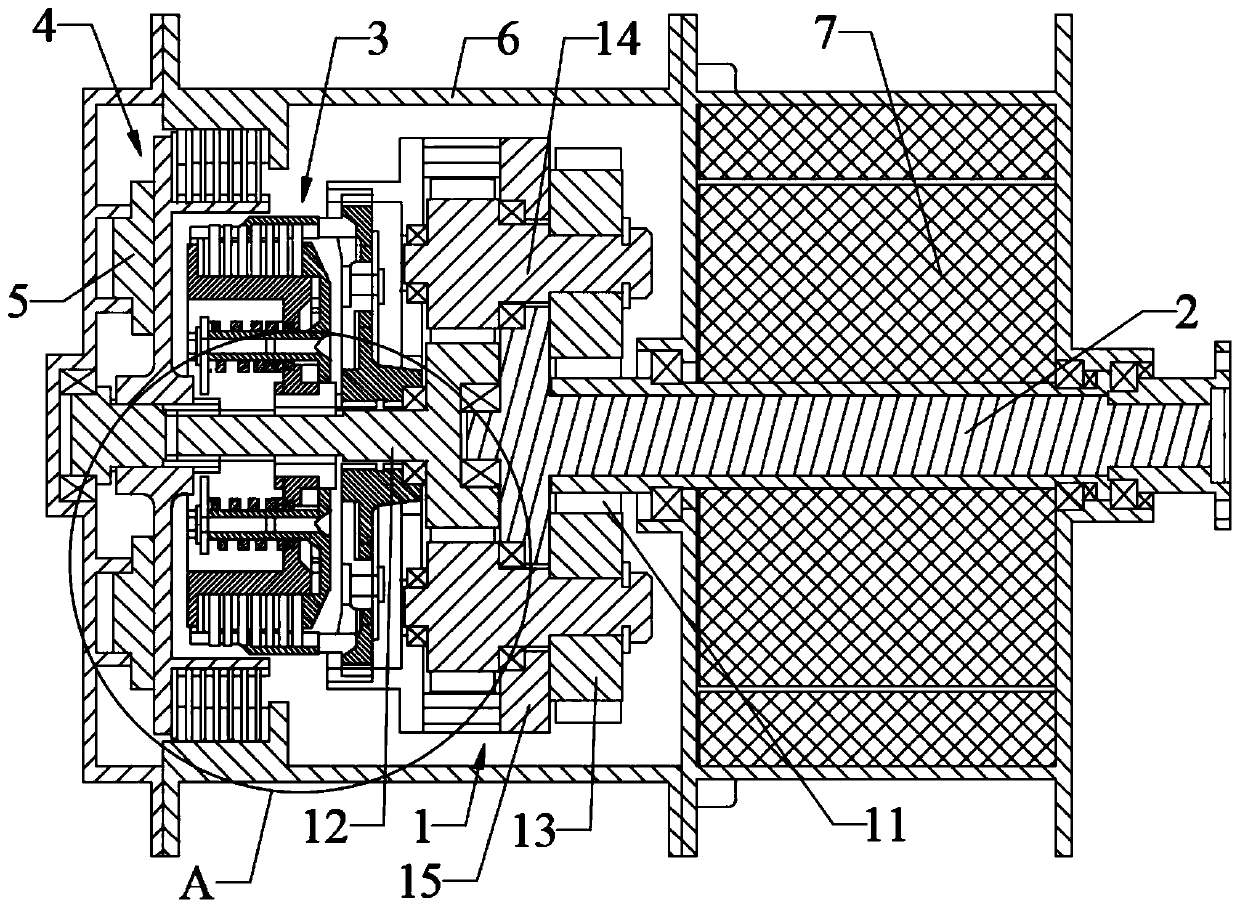

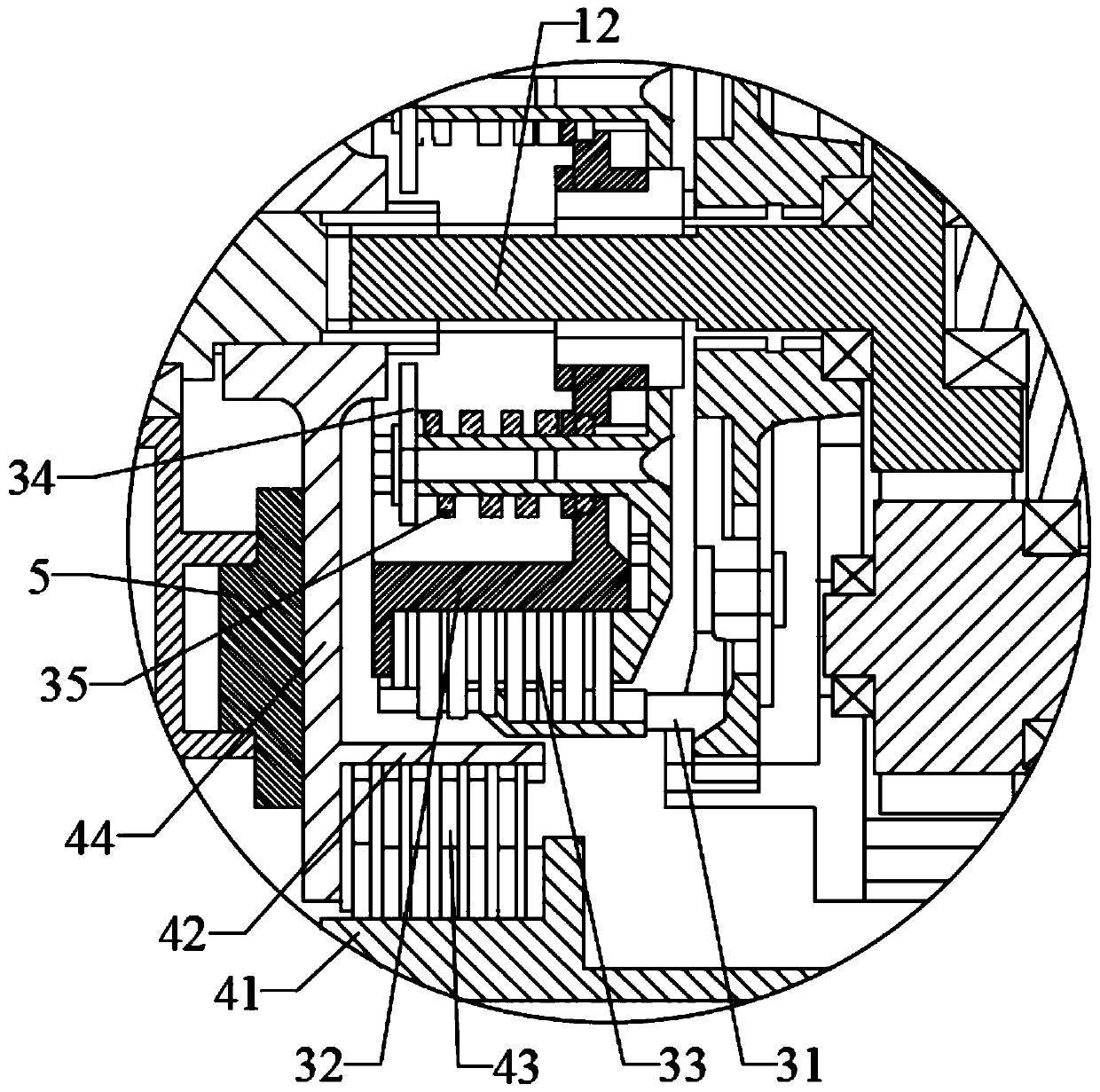

[0054] An automatic transmission device for an electric vehicle, comprising a planetary gear mechanism 1, an output shaft 2, a first clutch 3, a second clutch 4 and a shift mechanism 5 arranged in a housing 6;

[0055] The output shaft 2 is driven by a motor 7 through a planetary gear mechanism 1;

[0056] The shift mechanism 5 controls the linkage switching between the first clutch 3 and the second clutch 4, and the linkage switching between the first clutch 3 and the second clutch 4 controls the locking and unlocking of the planetary gear mechanism 1 so as to realize two switch between gears;

[0057] The planetary gear mechanism 1 includes a first sun gear 11, a second sun gear 12, a planetary gear and a planet carrier 15. The first sun gear 11 is sheathed on the output shaft 2 and is rotationally connected with the output shaft 2. The first sun gear 11 is driven by the motor 7, and one end of the first sun gear 11 and the planetary gear meshes with each other, and the oth...

Embodiment 2

[0066] An automatic transmission device for an electric vehicle, comprising a planetary gear mechanism 1, an output shaft 2, a first clutch 3, a second clutch 4 and a shift mechanism 5 arranged in a housing 6;

[0067] The output shaft 2 is driven by a motor 7 through a planetary gear mechanism 1;

[0068] The shift mechanism 5 controls the linkage switching between the first clutch 3 and the second clutch 4, and the linkage switching between the first clutch 3 and the second clutch 4 controls the locking and unlocking of the planetary gear mechanism 1 so as to realize two switch between gears;

[0069] The planetary gear mechanism 1 includes a first sun gear 11, a second sun gear 12, a planetary gear and a planet carrier 15. The first sun gear 11 is sheathed on the output shaft 2 and is rotationally connected with the output shaft 2. The first sun gear 11 is driven by the motor 7, and one end of the first sun gear 11 and the planetary gear meshes with each other, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com