Traction mechanism used between storage AGVs

A traction mechanism and warehousing technology, applied in the field of warehousing and logistics, can solve the problems of difficulty in meeting the requirements of fast and accurate warehouse management, affecting the operation efficiency of enterprises, slow data entry and other problems, achieving convenient and fast connection, compact structure, and safe and reliable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

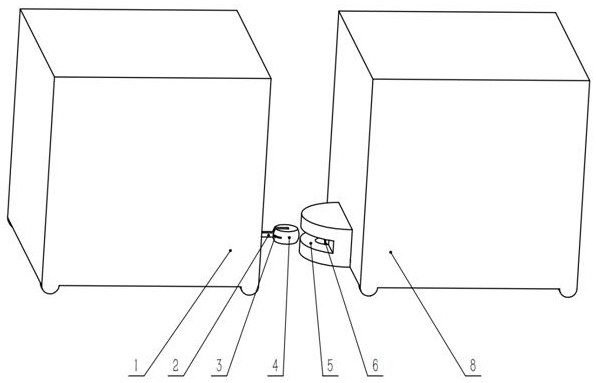

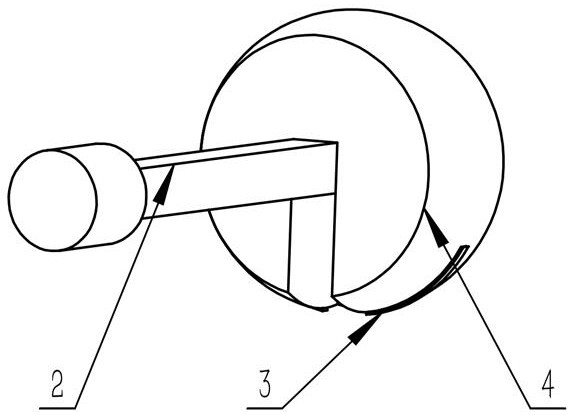

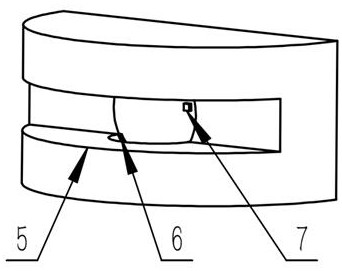

[0021] As shown in the figure, a traction mechanism used for storage between AGVs includes a front car 8 and a rear car 1 arranged front and rear; The front end of the rear car 1 is fixedly connected, and the front end is matched with a swivel joint 4. The swivel joint 4 is a disc-shaped structure, and the middle part of its top surface is provided with a bar-shaped slot that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com