Orthogonal stress state controllable direct shear test device and test method

A technology of stress state and test device, applied in the direction of measuring device, using stable shear force to test material strength, instrument, etc., can solve the problems of shear strength parameter influence, large difference, waste of economic cost, etc., to avoid Uncontrollable effects of lateral confining pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

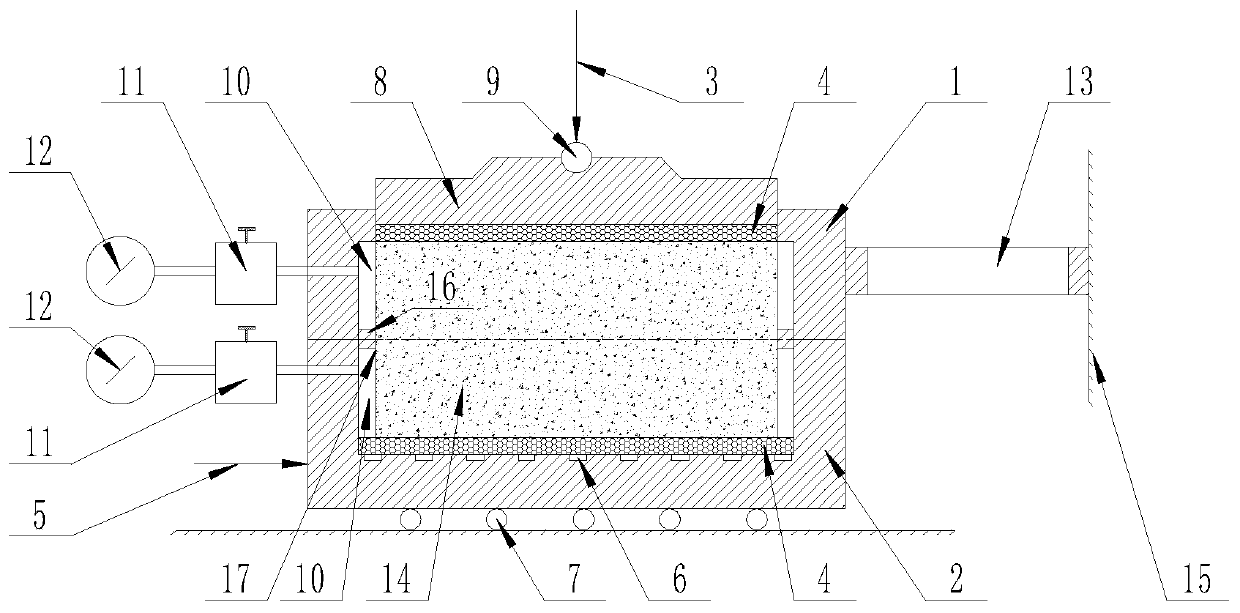

[0044] according to figure 1 and figure 2 A direct shear test device with controllable orthogonal stress state is shown, including

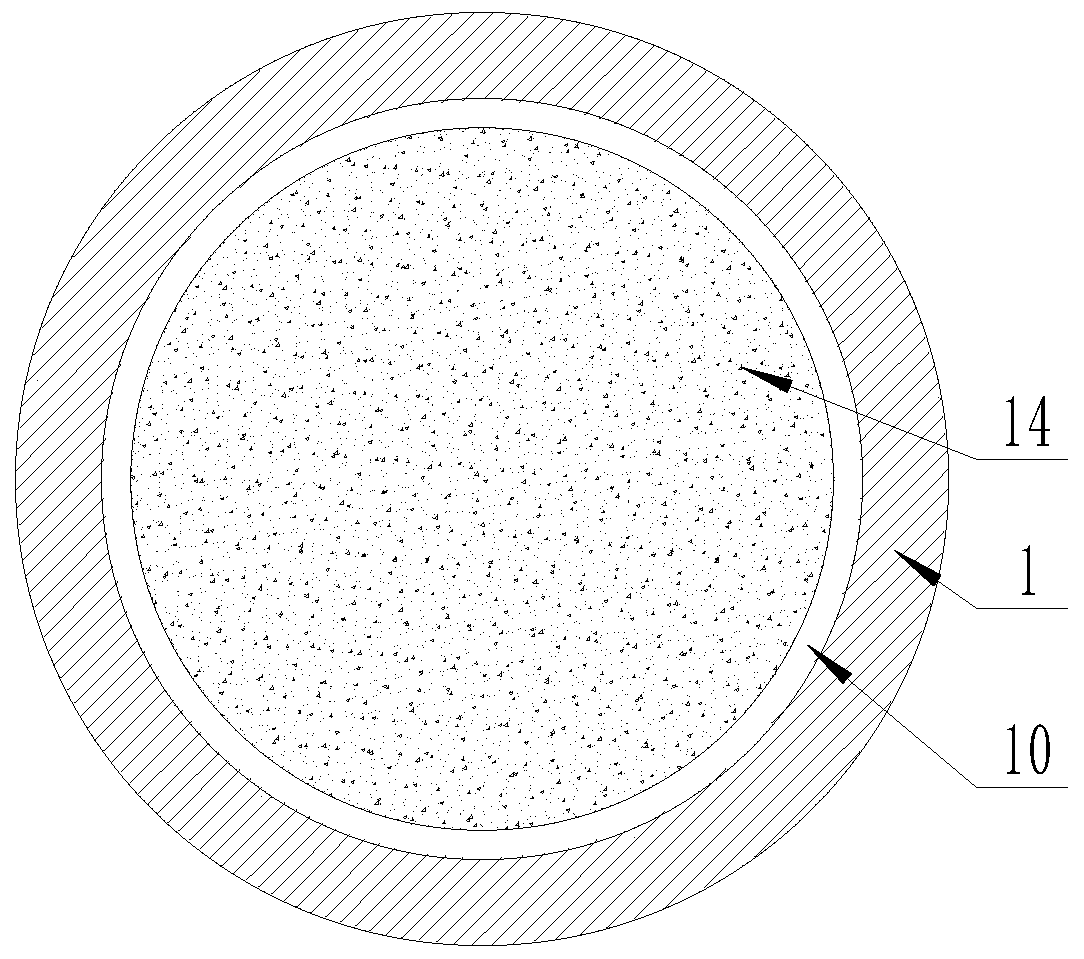

[0045] Cutting box, the cutting box is a circular box body composed of an upper cutting box 1 and a lower cutting box 2 arranged up and down, and a circular cavity is arranged in the cutting box;

[0046] a sliding mechanism, the sliding mechanism is slidingly connected to the lower bottom surface of the lower shear box 2;

[0047] A horizontal loading device 5, which is connected to the outer side wall of the lower shear box 2;

[0048] Fixing device, the fixing device is connected on the outer side wall of the upper shear box 1 opposite to the horizontal loading device 5;

[0049] The vertical loading component 3 is arranged on the top of the upper shear box 1;

[0050] A confining pressure control device connected to the side walls of the upper shear box 1 and the lower shear box 2;

[0051] The water permeable mechanism is arranged in t...

Embodiment 2

[0056] according to figure 1 The shown direct shear test device with controllable orthogonal stress state is different from the first embodiment in that: the water permeable mechanism is two permeable stones 4; one of the permeable stones 4 is arranged on the bottom surface of the lower shear box 2 On the top, another permeable stone 4 is arranged on the lower surface of the vertical loading assembly 3 .

[0057] Preferably described water permeable mechanism also comprises drain hole 6; Described drain hole 9 is blind hole or through hole, is arranged on lower shear box 2 bottom surfaces.

[0058] In actual use, the moisture squeezed out during the drainage and consolidation process of the sample 14 under the original stress state is absorbed by the permeable stone 4, so that the sample 14 can be better and quickly consolidated.

[0059] When the moisture in the sample is not much, only the permeable stone 4 can be used to absorb water. When the moisture contained in the sam...

Embodiment 3

[0062] according to figure 1 The shown direct shear test device with controllable orthogonal stress state is different from the first embodiment in that: the sliding mechanism is composed of multiple pulleys 7; the multiple pulleys 7 are evenly arranged in the lower shear box 2 under the bottom.

[0063] In actual use, the sliding mechanism adopts the technical scheme of a plurality of pulleys 7, which can not only guarantee to meet the requirements of the test, but also save costs. In specific applications, the sliding mechanism can also adopt various methods such as slide rails. Any device can be used as long as it can move the shear box smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com