Optical axis adjusting assembly convenient for adjusting optical path

A technology for adjusting components and optical axes, applied in optical components, optics, installation, etc., can solve the problems of optical path readjustment, low adjustment accuracy, inconvenient adjustment, etc., to improve adjustment accuracy, ensure optical path sealing, simple and reliable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

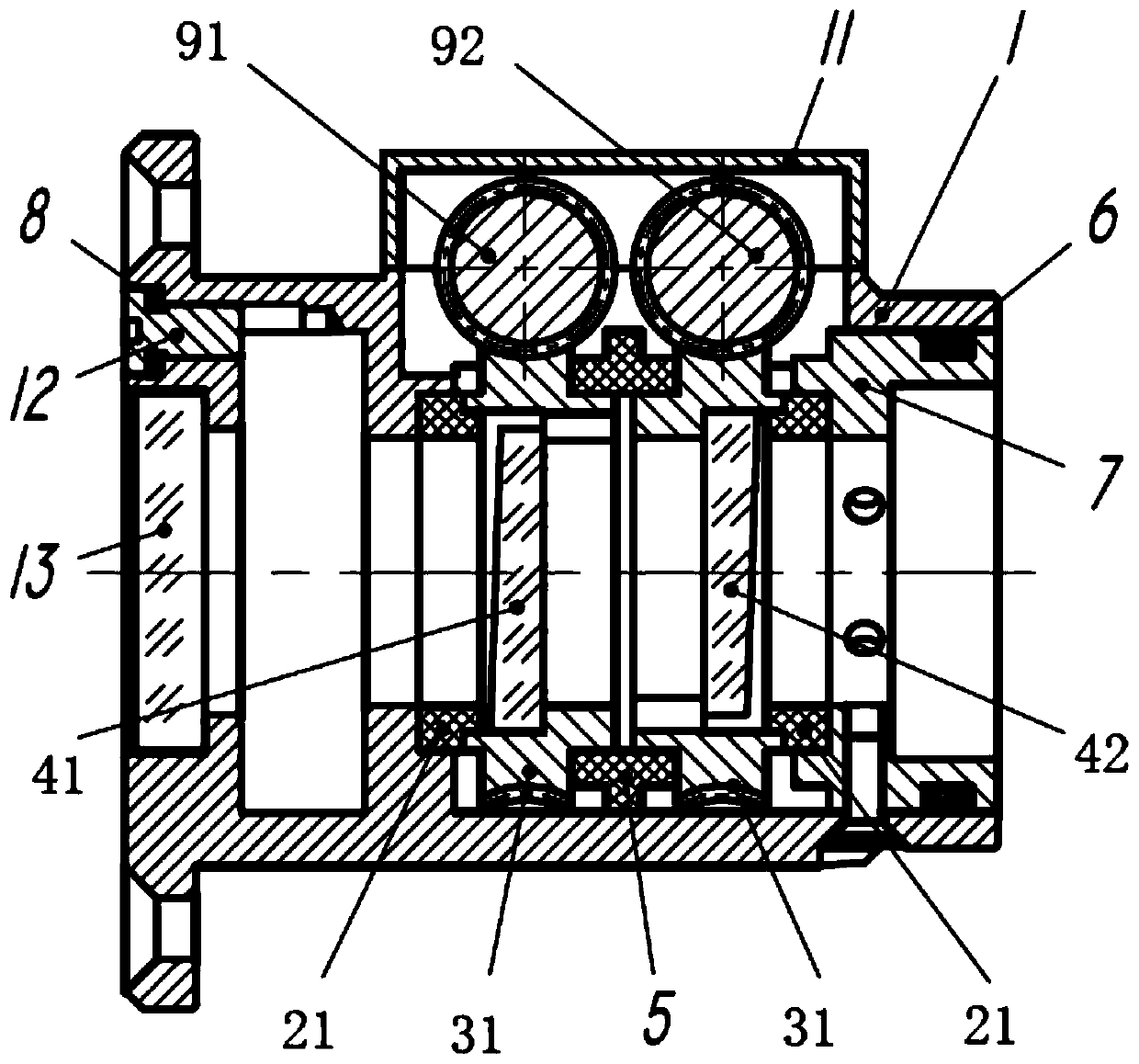

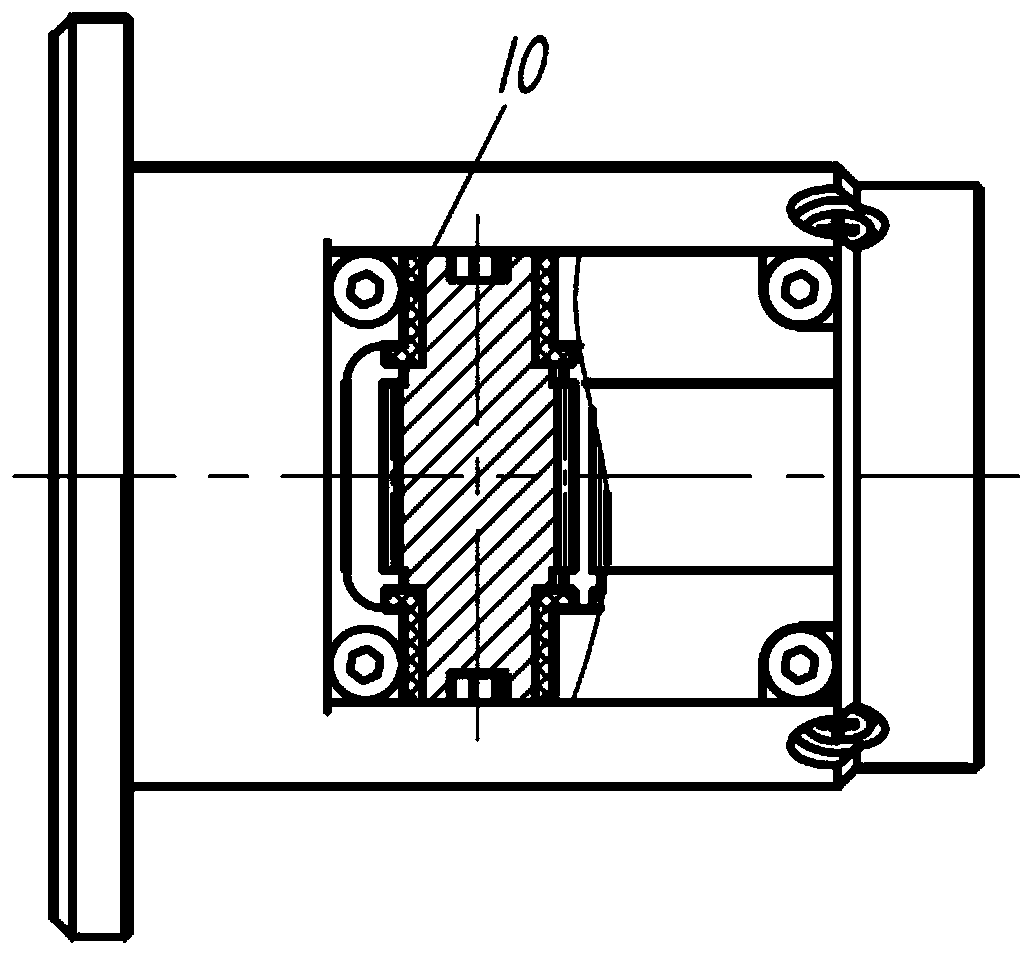

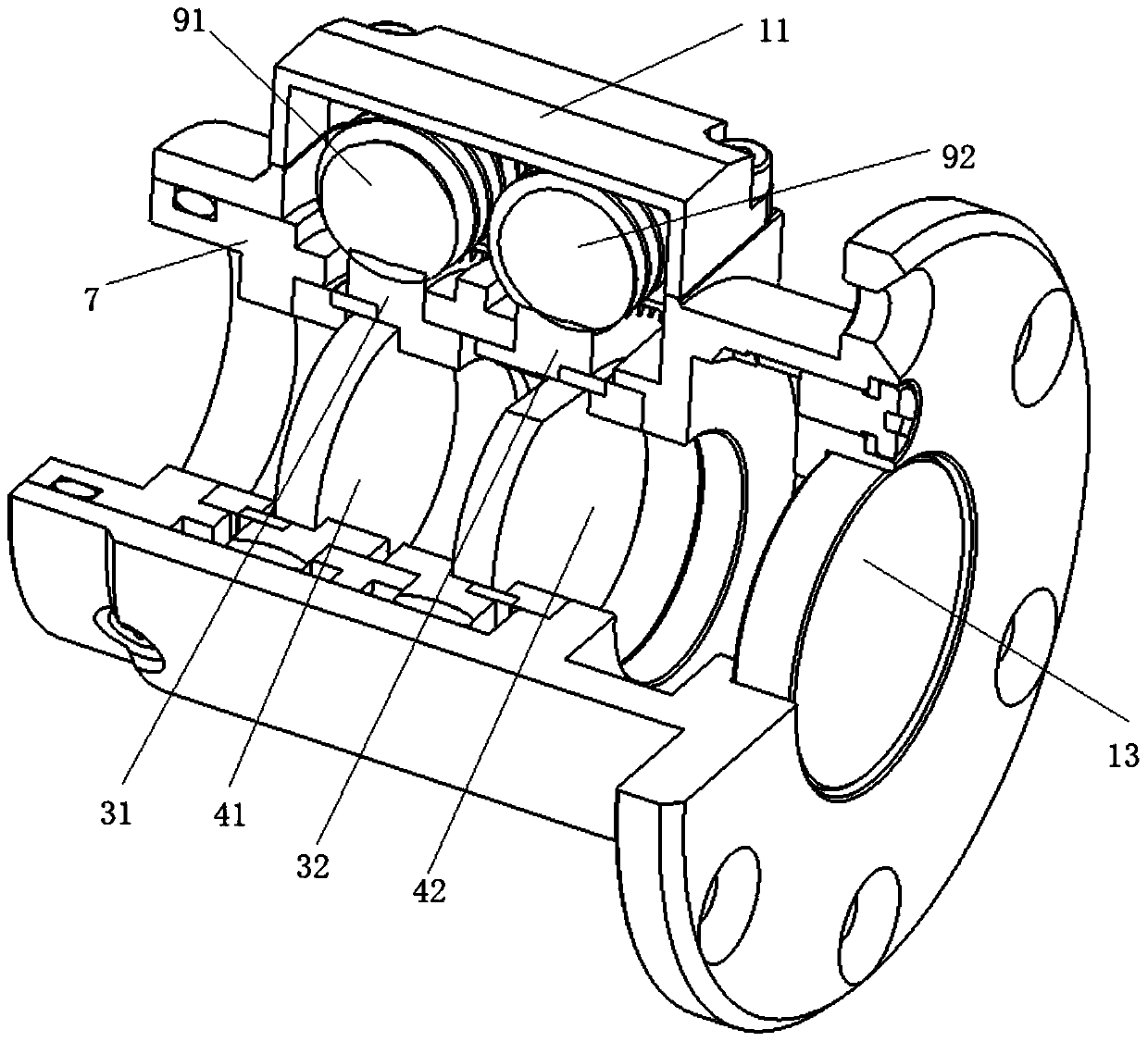

[0018] combine figure 1 , an optical axis adjustment assembly for adjusting the optical path of the present invention, including an optical wedge mount 1, a first worm wheel pressure ring 21, a second worm wheel pressure ring 22, a first worm wheel 31, a second worm wheel 32, a first wedge mirror 41. Second wedge mirror 42, worm wheel spacer 5, worm wheel pressing plate 7, first worm 91, second worm 92, worm pressing plate 11, sealing screw 12, dustproof mirror 13;

[0019] The first wedge mirror 41 is fixed in the center hole of the first turbine 31, and the second wedge mirror 42 is fixed in the center hole of the second turbine 32; between the first wedge mirror 41 and the first turbine 31, the second wedge A ventilation hole is provided between the mirror 42 and the second turbine 32; the first turbine 31 and the second turbine 32 are coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com