Method for predicting gap between model tail cavity and supporting rod for wind tunnel test

A prediction method and model technology, applied in the field of experimental fluid mechanics, can solve the problems of unavailable collision prediction, unpredictability, and no real effect, etc., and achieve the effect of convenient implementation, improvement of experimental accuracy and efficiency, and saving experimental resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below. Those who do not indicate the specific conditions in the examples are carried out according to the conventional conditions or the conditions suggested by the manufacturer.

[0015] The method for predicting the gap between the model tail cavity and the strut used in the wind tunnel test provided by the embodiment of the present invention will be described in detail below.

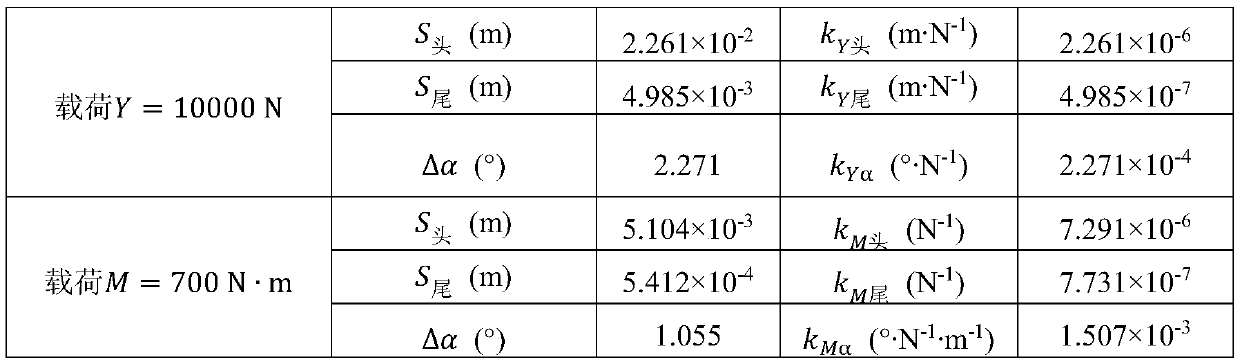

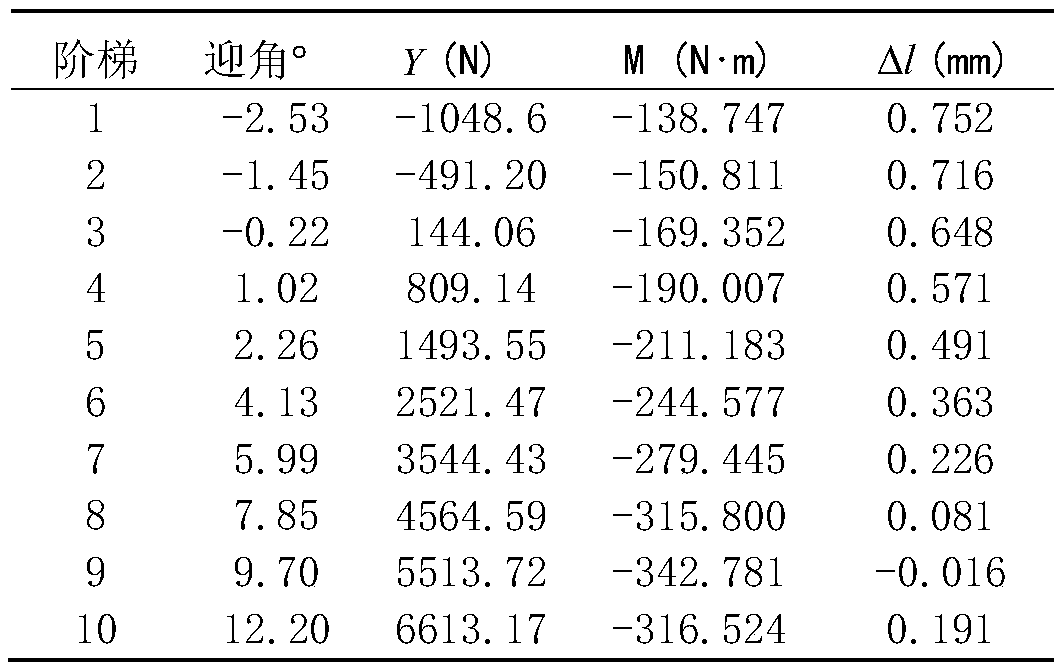

[0016] The embodiment of the present invention provides a method for predicting the gap between the model tail cavity and the strut for wind tunnel tests, which includes: using the difference between the physical data and the characteristic data to characterize the gap between the model tail cavity and the strut gap.

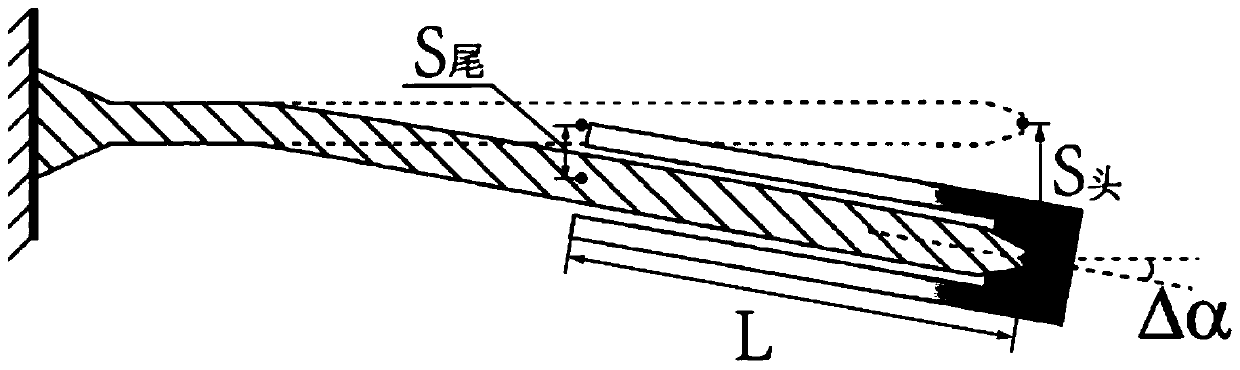

[0017] can be combined figure 1 , the physical dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com