Method and device for predicting fatigue failure of drive shaft of horizontal conveying device

A device-driven, fatigue-failure technology, applied in the field of mechanical equipment and mechanical equipment data analysis, can solve problems such as inability to adapt to production site capacity adjustments and changes, and achieve low cost, improved accuracy and convenience, and simple implementation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

[0043] see figure 1 As shown, it is a flow chart of the steps of the method for predicting the fatigue failure of the driving shaft of the horizontal conveying equipment according to the present invention.

[0044] In one embodiment, the method for predicting fatigue failure of drive shafts of horizontal conveying equipment includes the following steps:

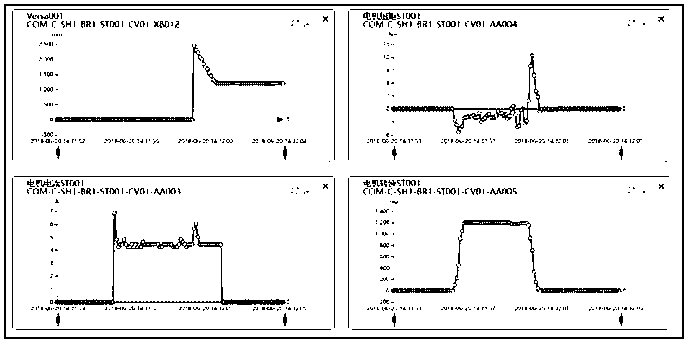

[0045] (1) According to the actual working condition of the drive shaft, periodically collect the stress data of the drive shaft through the sensor;

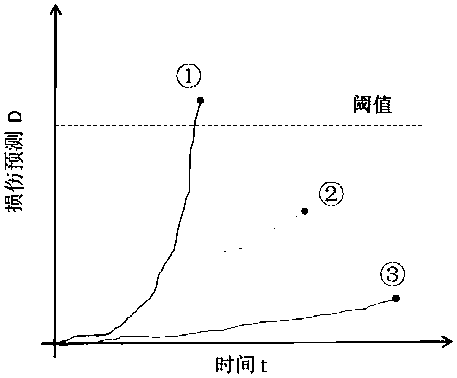

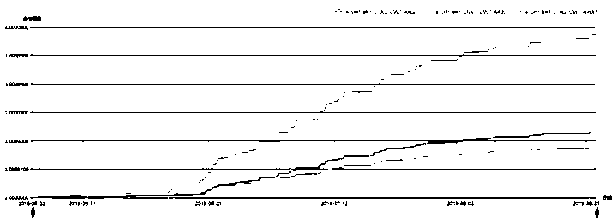

[0046] (2) Determine whether the stress data collected in each cycle exceeds the preset range, and if so, accumulate the damage value;

[0047] (3) Judging whether the damage value reaches the threshold, and if so, a warning is issued.

[0048] In a preferred embodiment, the step (1) specifically includes the following steps:

[0049] (11)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com