Surfactant bubble dust removal device and dust removal method

A technology of surfactant and dust removal device, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of insufficient dust removal efficiency and large water consumption, and achieve reduced dust control costs, less water consumption, and surface low tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

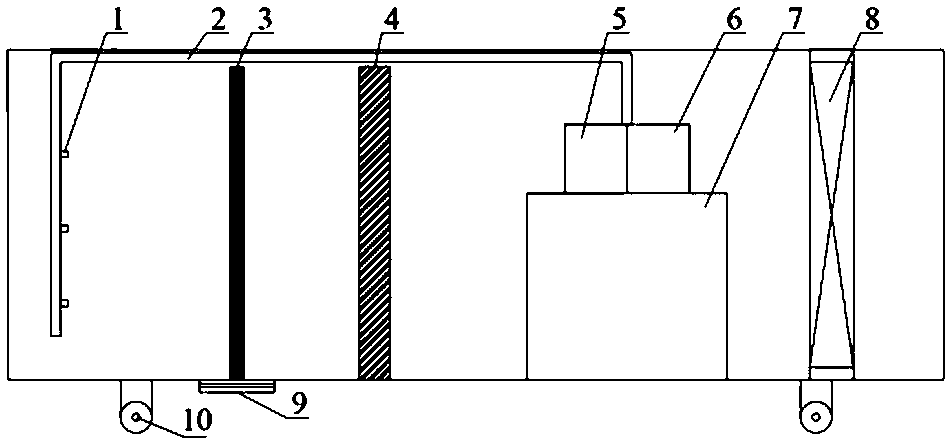

[0027] like figure 1 As shown, the present invention includes a housing, a bubble generating assembly 1 , a filter plate 3 , a water baffle 4 , a liquid storage tank 4 , a blower fan 5 , a water pump 6 , a liquid storage tank 7 and a blower fan 8 . The housing is a cylindrical structure with two ends open, the cross-section of the housing is square, and the bottom of the housing is provided with a universal wheel 10 . The air bubble generating assembly 1, the filter plate 3, the water retaining plate 4 and the fan 8 are arranged in the casing, and the fan 8 is an axial flow fan.

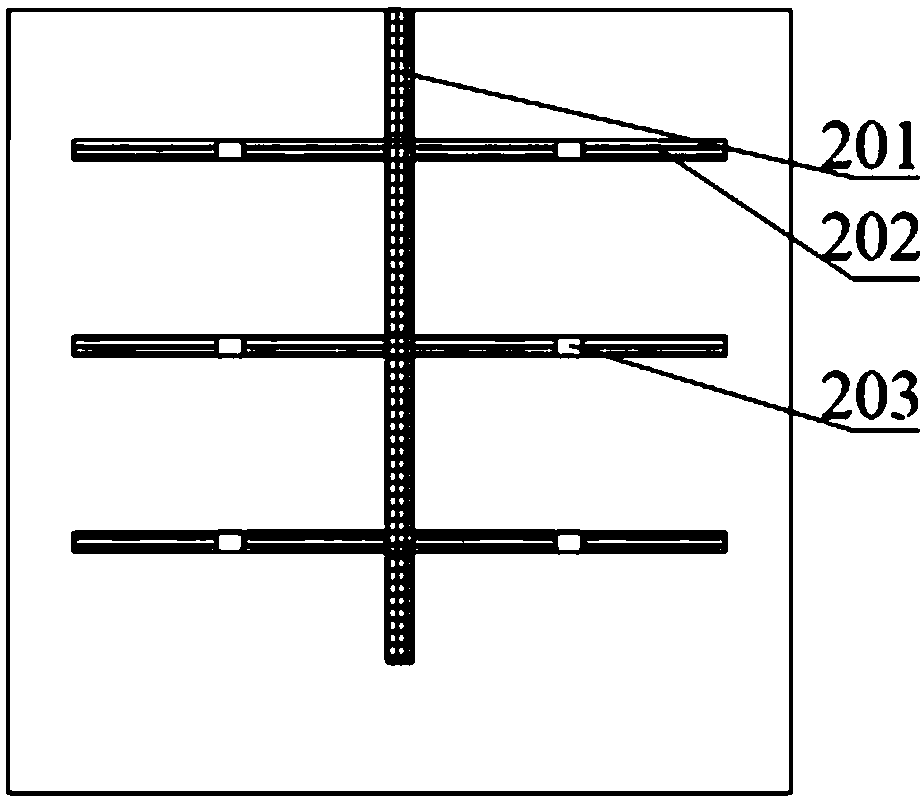

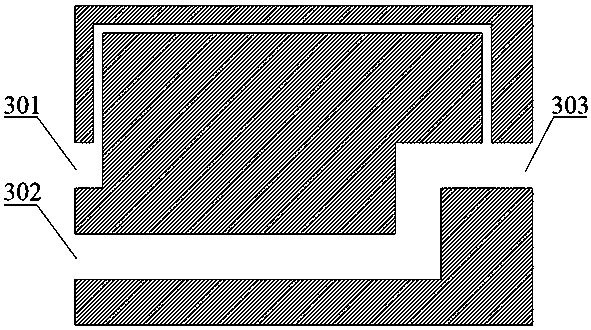

[0028] like figure 2 As shown, the air bubble generating assembly 1 includes a plurality of air bubble nozzles, an air inlet pipe and a water inlet pipe; A main pipe and a plurality of intake branch pipes connected in parallel on the air intake main pipe. like image 3 As shown, the bub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com