Automatic conveying, detecting and outputting method for rubber shell of through-beam photoelectric switch

A photoelectric switch and automatic conveying technology, applied in electrical switches, conveyors, conveyor objects, etc., can solve the problems of high production cost, low production efficiency and poor quality, and achieve low production cost, high production efficiency and good quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

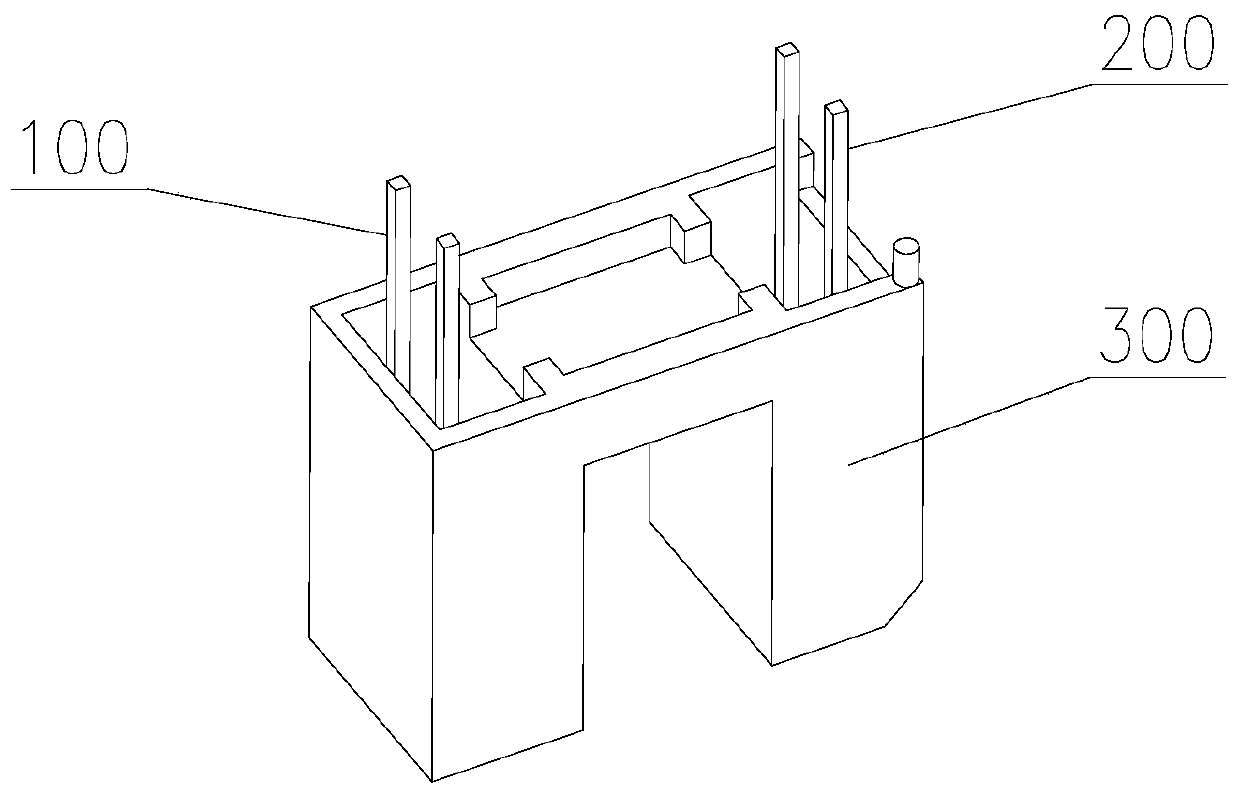

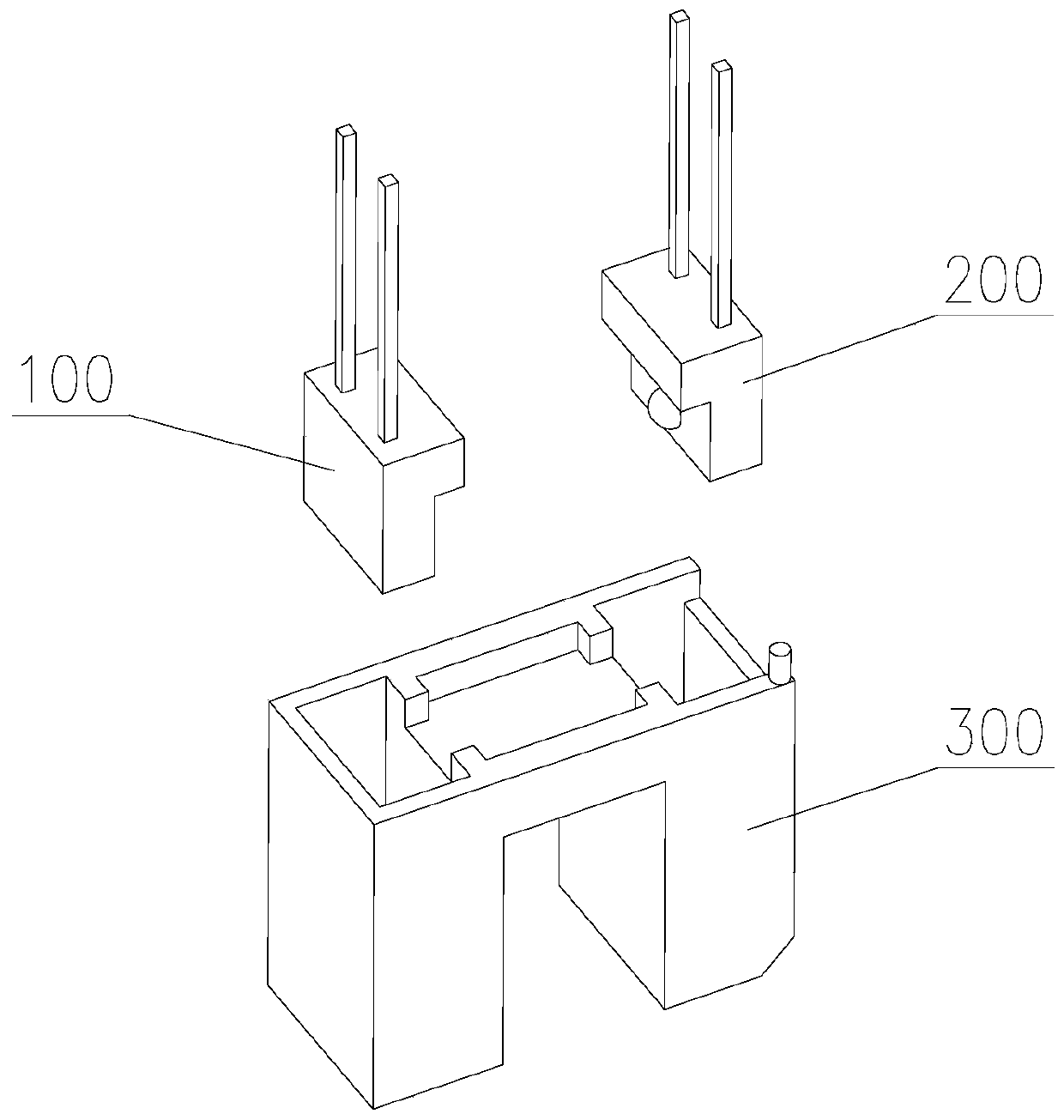

[0104] Such as figure 1 As shown, the through-beam photoelectric switch is made by installing the emitting LED100 and the receiving LED200 in the plastic case 300 . The emitting LED 100 and receiving LED 200 are manufactured separately. When assembling, the emitting LED 100 and the receiving LED 200 are inserted into the plastic case 300 and fixed. The plastic case 300 is also provided with protrusions for identifying directions. At present, the assembly of reflective photoelectric switches is carried out manually, and manual inspection is required for inspection. Manual feeding is still used for emitting LED100, receiving LED200 and plastic shell 300, and has not realized automatic transportation, inspection, assembly, output, and low production efficiency. , high production cost and poor quality.

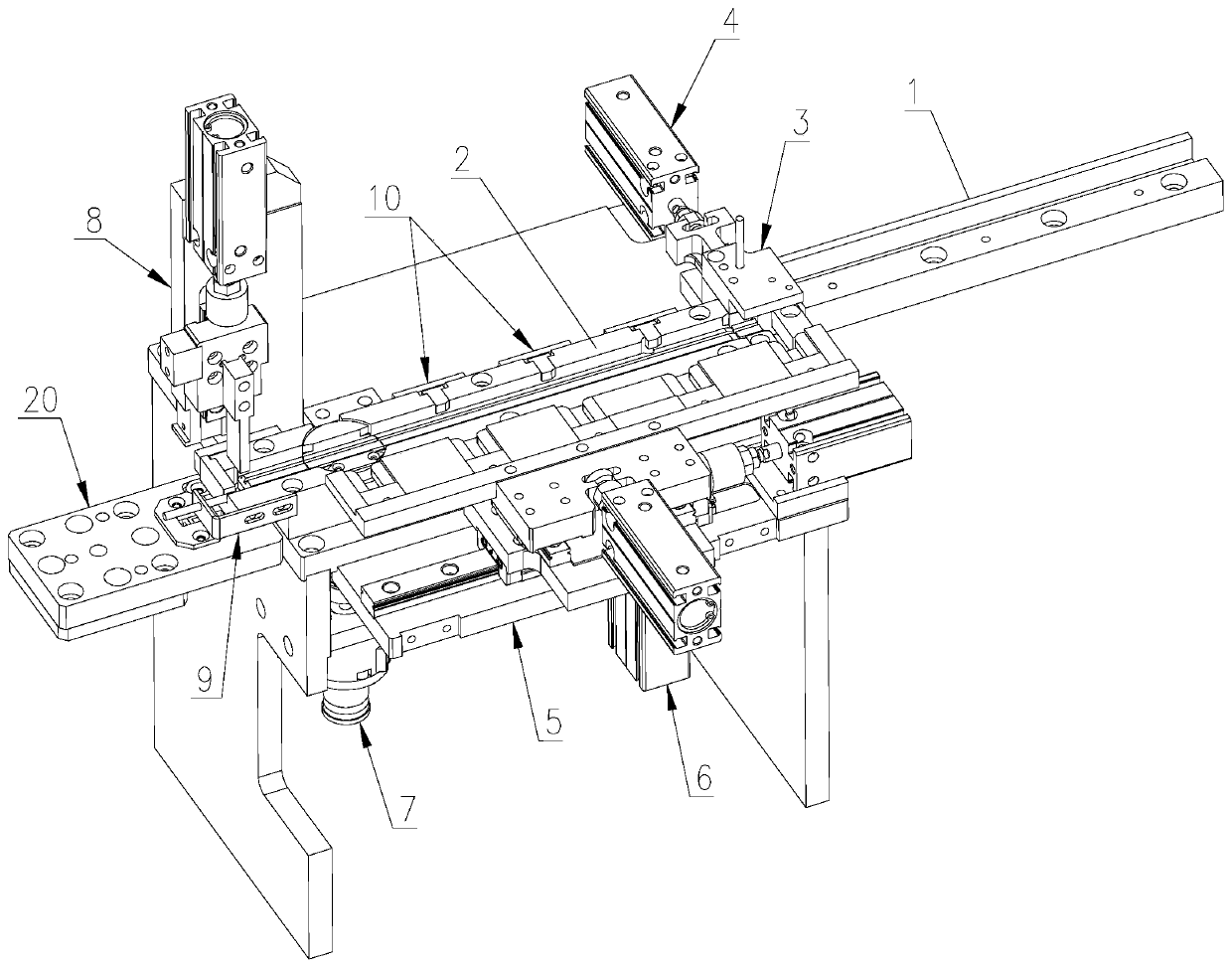

[0105] Such as image 3 , Figure 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com