Construction method for controlling integral position of column reinforcement

A construction method and column reinforcement technology, which is applied in the processing of building materials, construction, building reinforcements, etc., can solve problems such as column reinforcement deviation, and achieve the effects of controlling the position of column reinforcement, easy operation, and simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] process flow

[0012] Preparation of butterfly positioning card → installation of floor formwork → binding of beam reinforcement in place → nailing of butterfly pads → binding of floor reinforcement → pouring concrete → setting out wires to check the position of column reinforcement.

[0013] Butterfly positioning card preparation

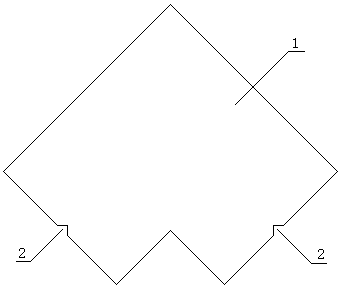

[0014] Select 0.5mm thick galvanized steel plate or stainless steel plate, adopt laser cutting method to press figure 1 The shapes shown are cut and fabricated.

[0015] Floor formwork installation

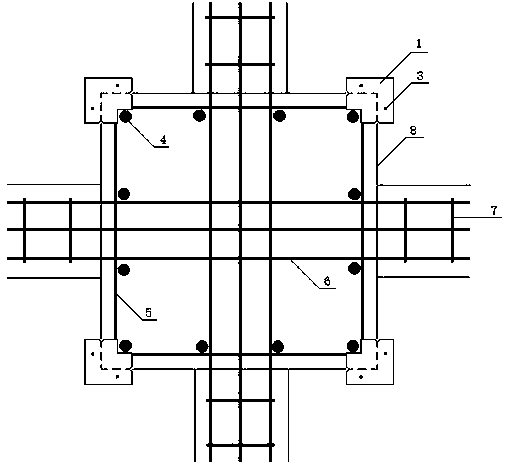

[0016] Set up the floor formwork support frame, place the beam bottom formwork, correct the position of the beam bottom formwork with the hanging wire, install the beam side formwork after fixing, and then install the flat formwork. The key point of this procedure is to guarantee the correctness and the squareness of the post mouth (8) position.

[0017] Beam reinforcement binding in place

[0018] The beam bars (6) are erected on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com