Method for packaging cadmium zinc telluride pixel detector module

A packaging method, cadmium zinc telluride technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of pixel electrode mechanical damage, large glue spots, poor bonding force of solder joints, etc., to reduce the external environment And the influence of external force, the effect of overcoming the open circuit problem and overcoming the short circuit problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

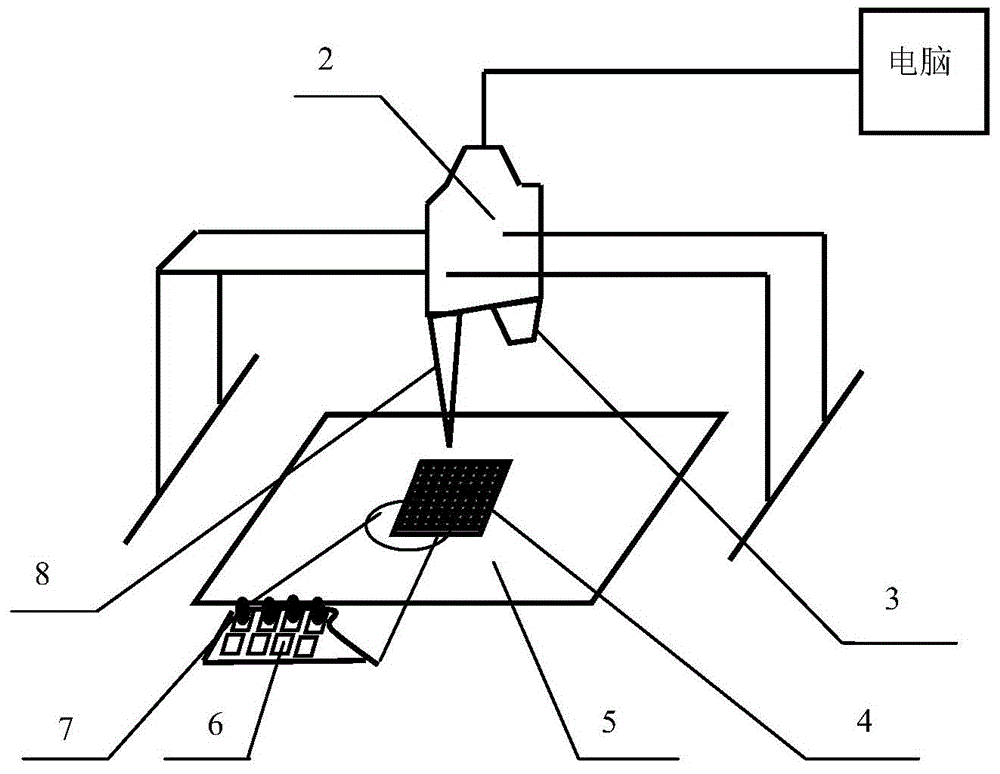

[0020] Step 1, using a CdZnTe single wafer to prepare an 8×8 array of CdZnTe pixel detector elements 1 . The substrate 4 for flip-chip connection corresponding to the size of the pixel electrode is designed. Then fix the substrate 4 made of PCB on the base 5 of the three-dimensional automatic dispensing machine, observe the position information of the substrate 4 through the CCD3 and transmit it to the computer, select the 8×8 matrix dispensing mode, and select the X-axis step to 1mm, The step of the Y axis is 1 mm, and input to the computer, the computer completes the matrix dispensing by controlling the movement of the three-dimensional translation platform 2, uniformly coats the silver conductive glue 7 on the metal electrode 6 of the substrate 4, and controls the single flow through the flow controller 8 The amount of dispensing.

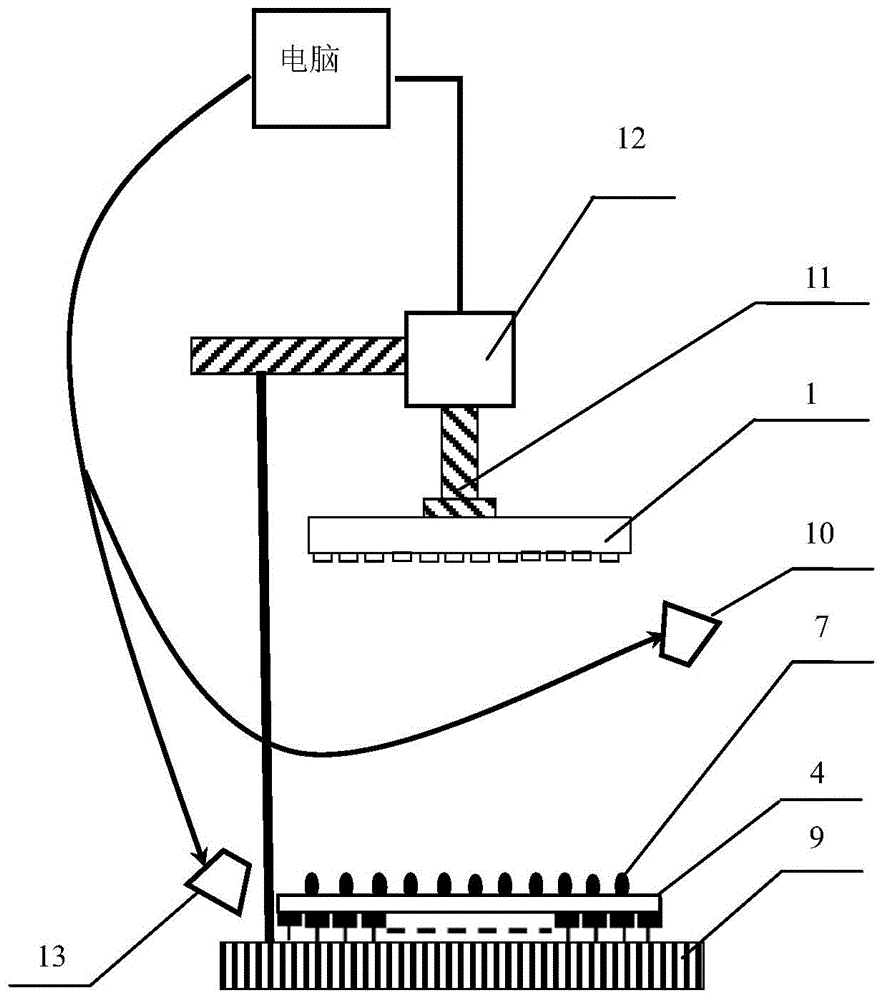

[0021] Step 2: Place the glued substrate 4 on the reference table 9 of the flip-chip bonding apparatus, record the image information on the su...

Embodiment 2

[0027] Step 1, using a CdZnTe single wafer to prepare a 20×20 array of CdZnTe pixel detector elements 1 . The substrate 4 for flip-chip connection corresponding to the size of the pixel electrode is designed. Then fix the ceramic substrate 4 on the base 5 of the three-dimensional automatic dispensing machine, observe the position information of the substrate 4 through the CCD3 and transmit it to the computer, select the 20×20 matrix dispensing mode, and select the X-axis step to 350 μm, The Y-axis step is 350 μm, and the step parameters are input into the computer. The computer completes the matrix dispensing by controlling the movement of the three-dimensional translation platform 2, and uniformly coats the silver conductive glue 7 on the metal electrode 6 of the substrate 4, and passes through the flow controller. 8 Control the amount of single dispensing.

[0028] Step 2: Place the glued substrate 4 on the reference table 9 of the flip-chip bonding apparatus, record the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com