Novel meat duck breeding cage

A technology for breeding cages and cages, applied in the field of breeding, can solve the problems of rising labor costs, high capital investment, large labor volume, etc., and achieve the effects of saving equipment space, improving breeding efficiency, and reducing economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

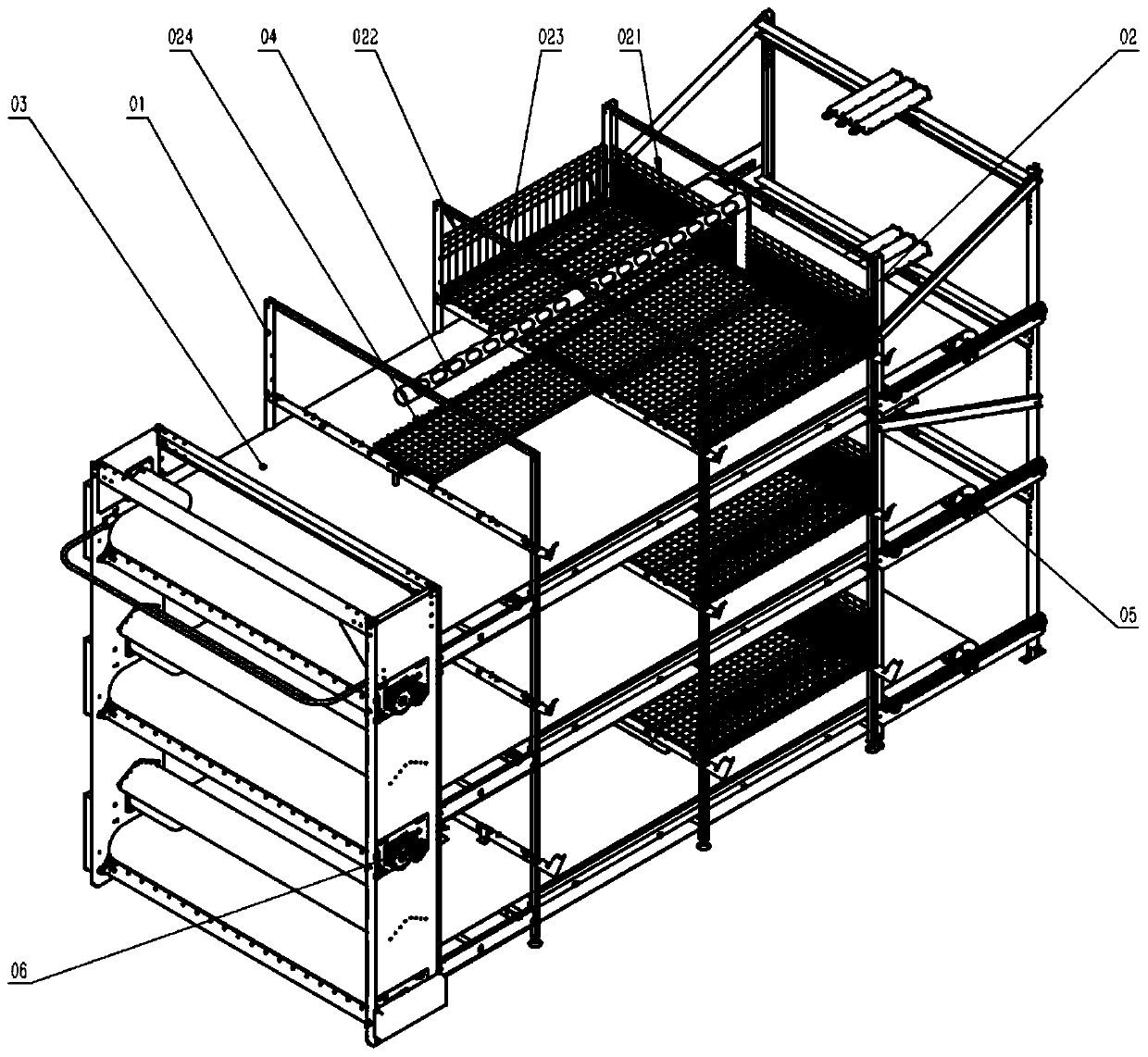

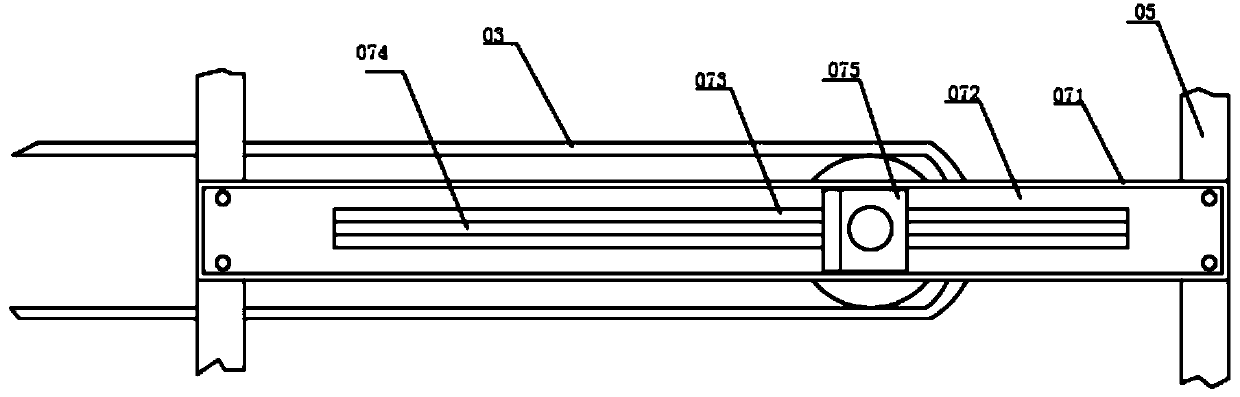

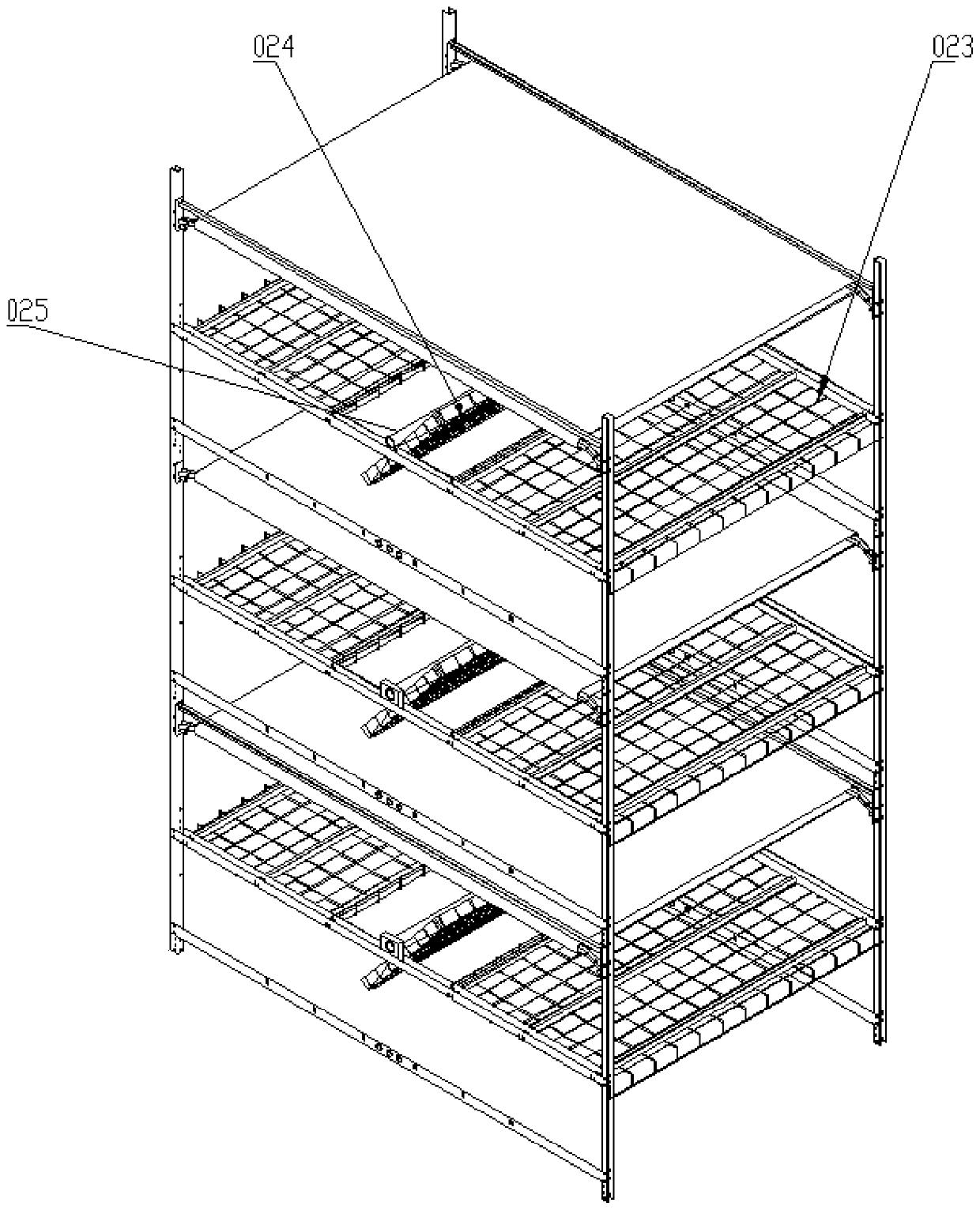

[0019] refer to Figure 1-Figure 4 As shown, the present invention provides a novel meat duck breeding cage, comprising a cage frame 01, a multi-layer excrement belt transmission mechanism 03 installed on the cage frame 01, a rearing frame installed on the cage frame 01, and mounted on the cage frame 01. The head end frame 05 on the front end of the cage frame 01, and the machine tail end frame 06 installed on the upper end of the cage frame 01, the feeding frame has the feeding assembly 02 with the same number of layers as the feces belt transmission mechanism 03, and the feeding assembly 02 is located at The meat duck drinking water assembly 04 is in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap