Assembled gypsum board ceiling system and lifting method

A gypsum board and prefabricated technology, applied in the direction of ceilings, building components, buildings, etc., can solve the problems of many construction procedures and long construction period, and achieve the effect of simple fixing method, improved structural stability and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

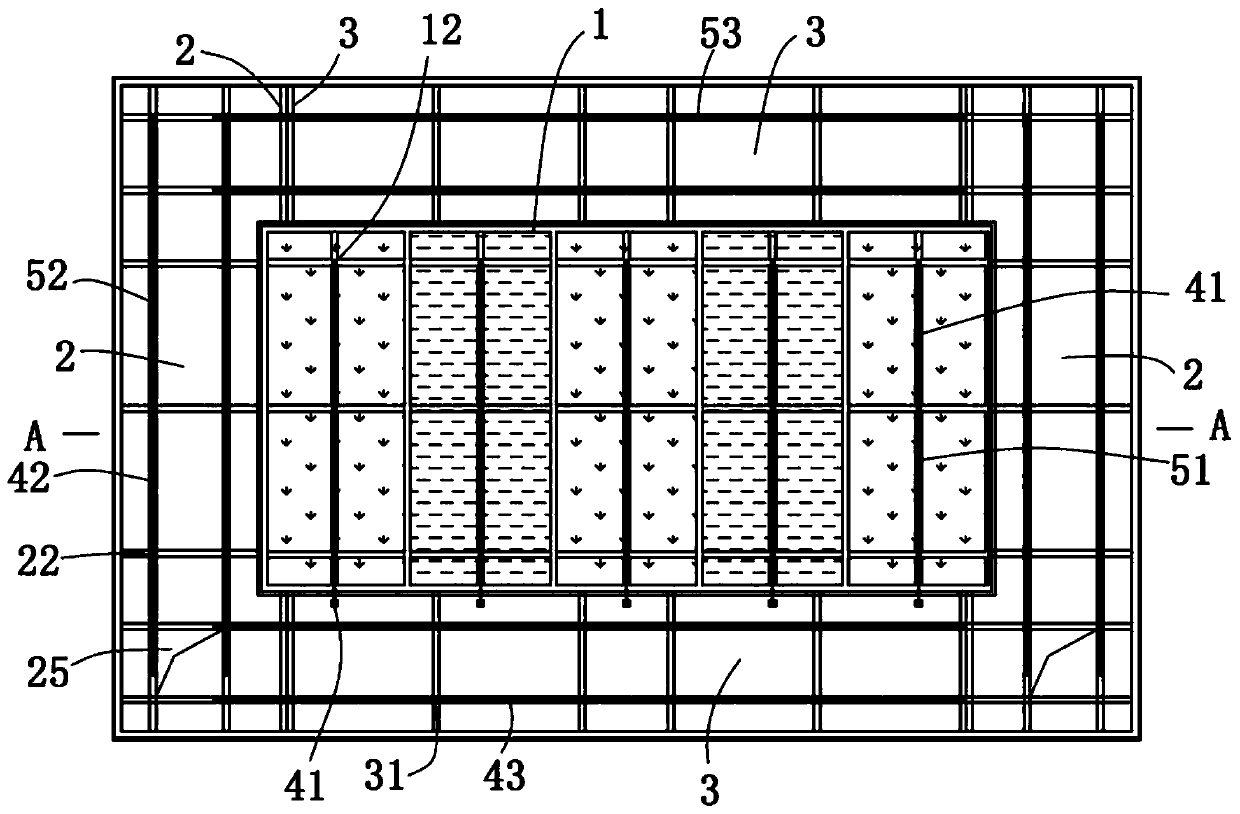

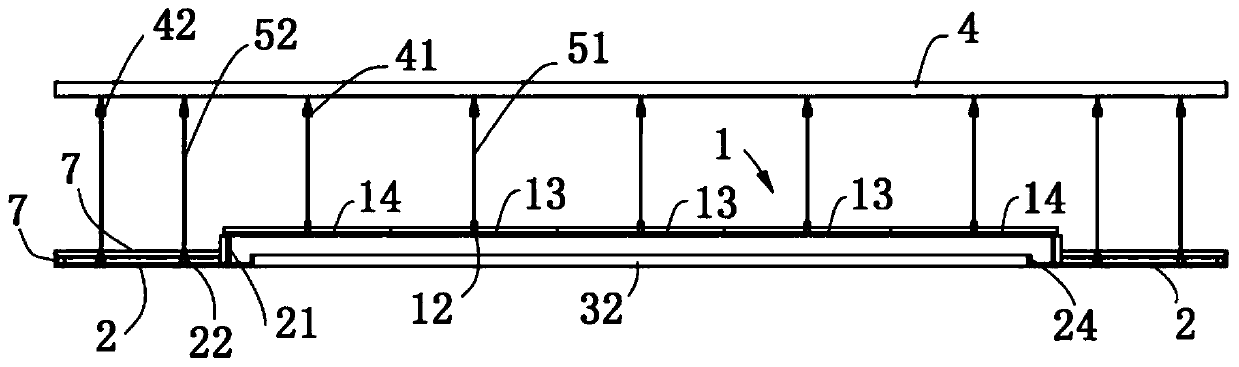

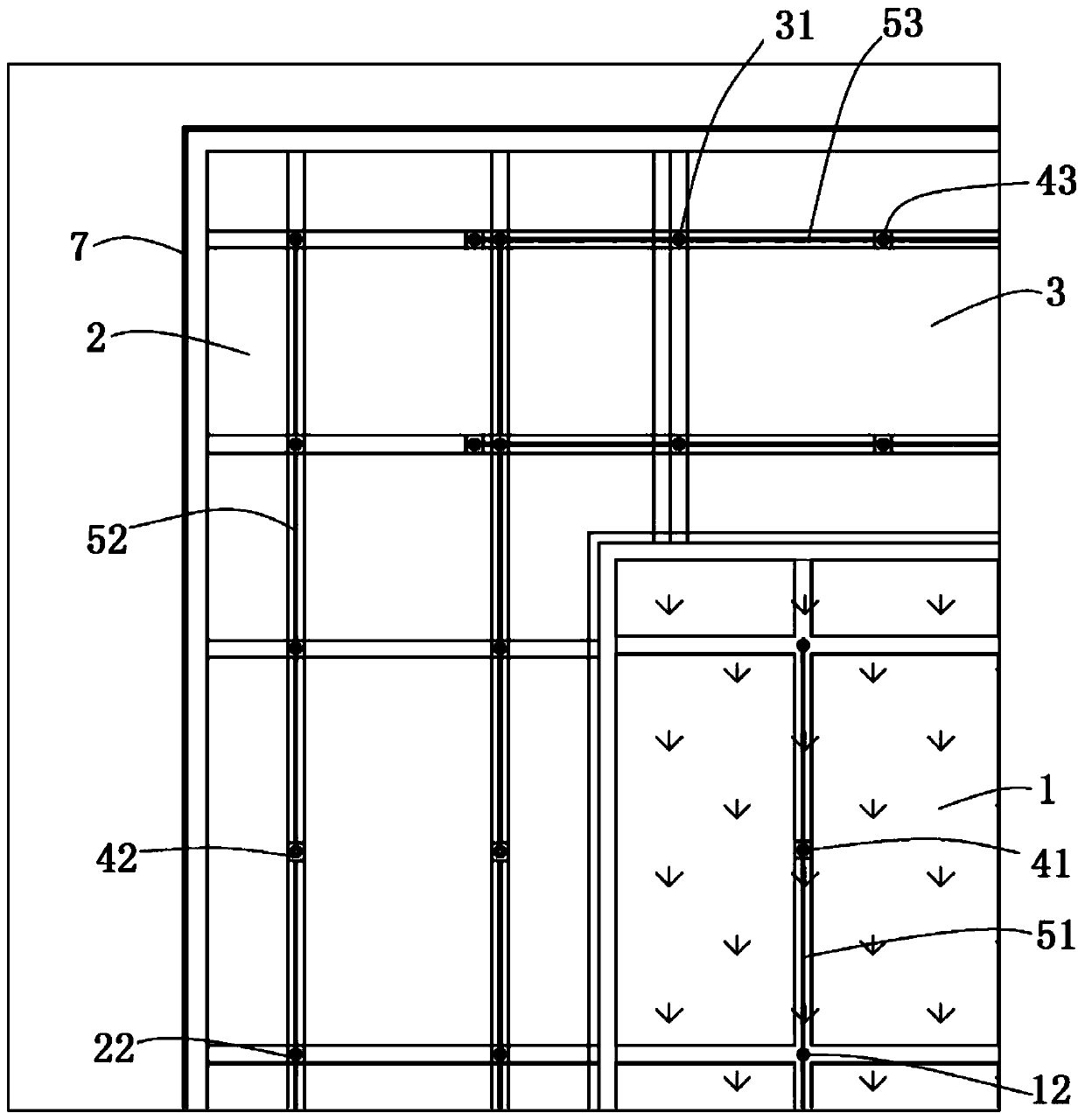

[0035] see figure 1 , figure 2 As shown, the present invention provides an integrated assembled gypsum board ceiling system, including: a first unit panel 1 , a second unit panel 2 and a third unit panel 3 , which are used to form an integrated assembled ceiling system at the bottom of the structural floor 4 .

[0036] Specifically, as figure 2 , Figure 4 As shown, the first unit panel 1 is hoisted at the bottom of the structural floor 4, and grooves 11 are provided on the opposite first side and the bottom surface of the second side of the first unit panel 1; The board 2 is suspended below the first side and the second side of the first unit board 1, and the side of the second unit board 2 close to the first unit board 1 extends to the adjacent side The bottom of the groove 11 is provided with a verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com