Cuff shaping device

A technology of setting device and chassis, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problem of easy movement of control pedals, and achieve the effect of avoiding damage to electrical components and preventing line damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

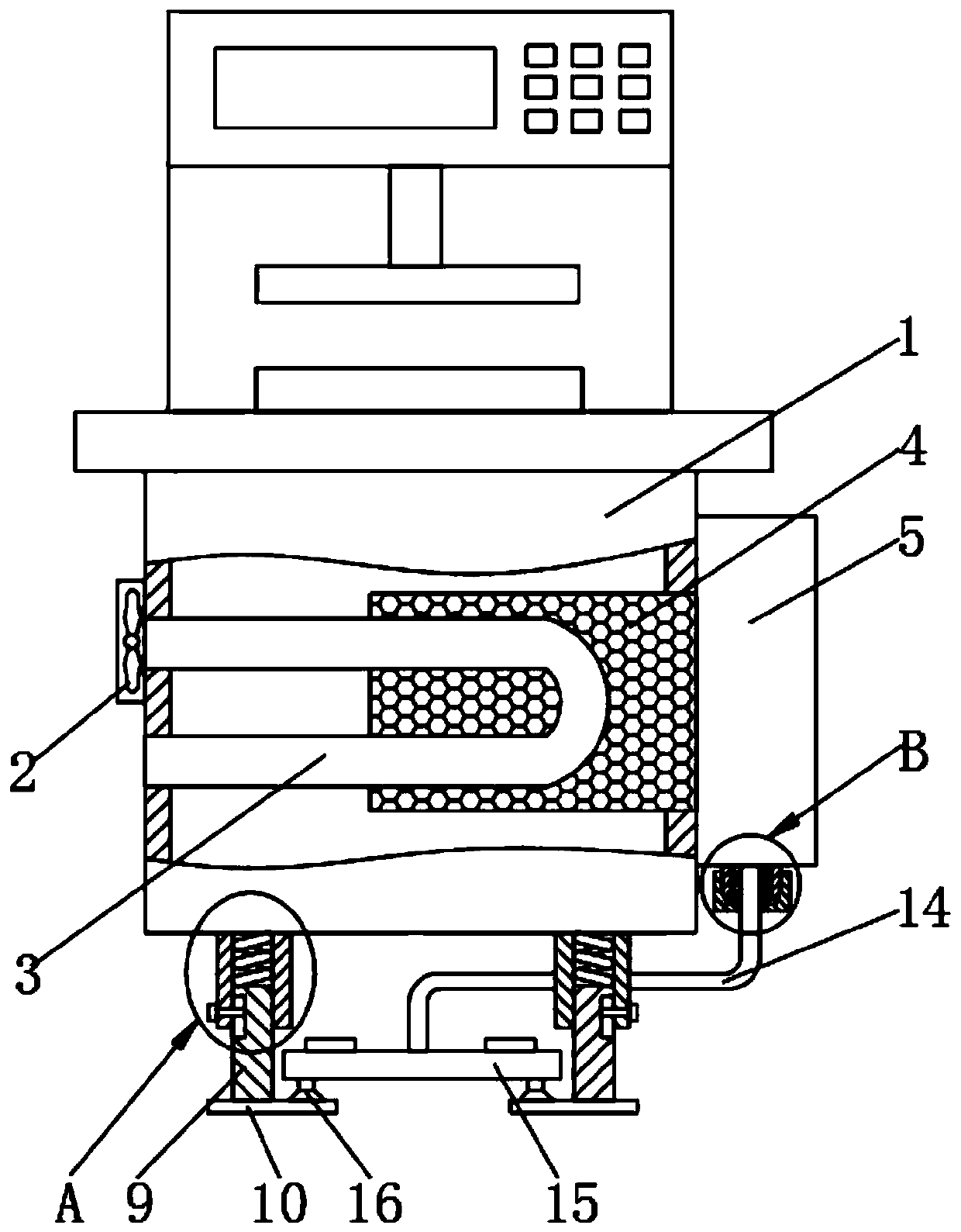

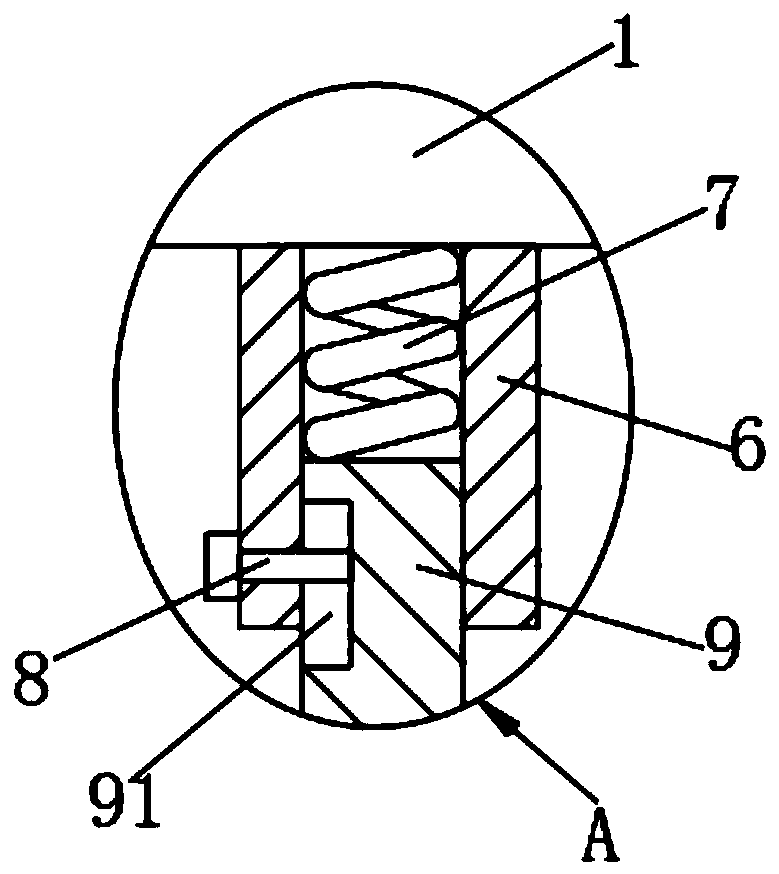

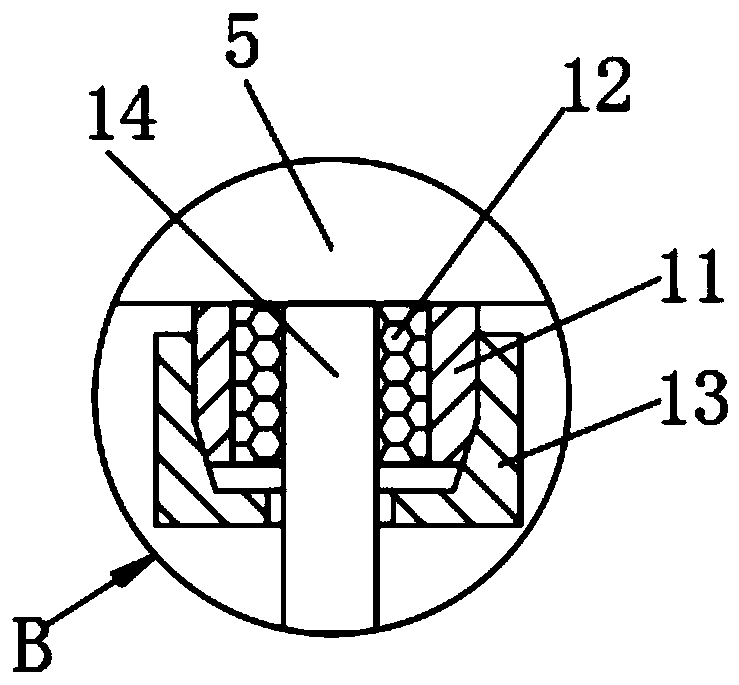

[0022] see Figure 1-5 , a cuff shaping device, comprising a case 1, a fan 2 is fixedly installed on the left end of the case 1, a heat dissipation pipe 3 is welded inside the case 1, a heat-conducting silica gel block 4 is attached to the outside of the heat dissipation pipe 3, and a right end of the case 1 is fixedly installed There is a control box 5, and various electrical components are installed in the control box 5, which belongs to the prior art. The lower end of the cabinet 1 is welded with a connecting sleeve 6, and a spring 7 is installed inside the connecting sleeve 6. The spring 7 has a shock-absorbing effect, and the connecting sleeve 6 The limit nail 8 is threaded inside, the guide column 9 is slidably connected to the connecting sleeve 6, the lower end of the guide column 9 is welded with a foot plate 10, the lower end of the control box 5 is welded with a threaded sleeve 11, and the control box 5 is led out with a wire 14. The outer side of 14 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com