Cross-over pipeline structure

A technology for bridging pipes and pipes, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc. It can solve the problems of increased thermal expansion displacement, restrictions, and high pressure of external transportation pipelines, so as to save engineering costs and avoid pipelines. The effect of damaging or improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

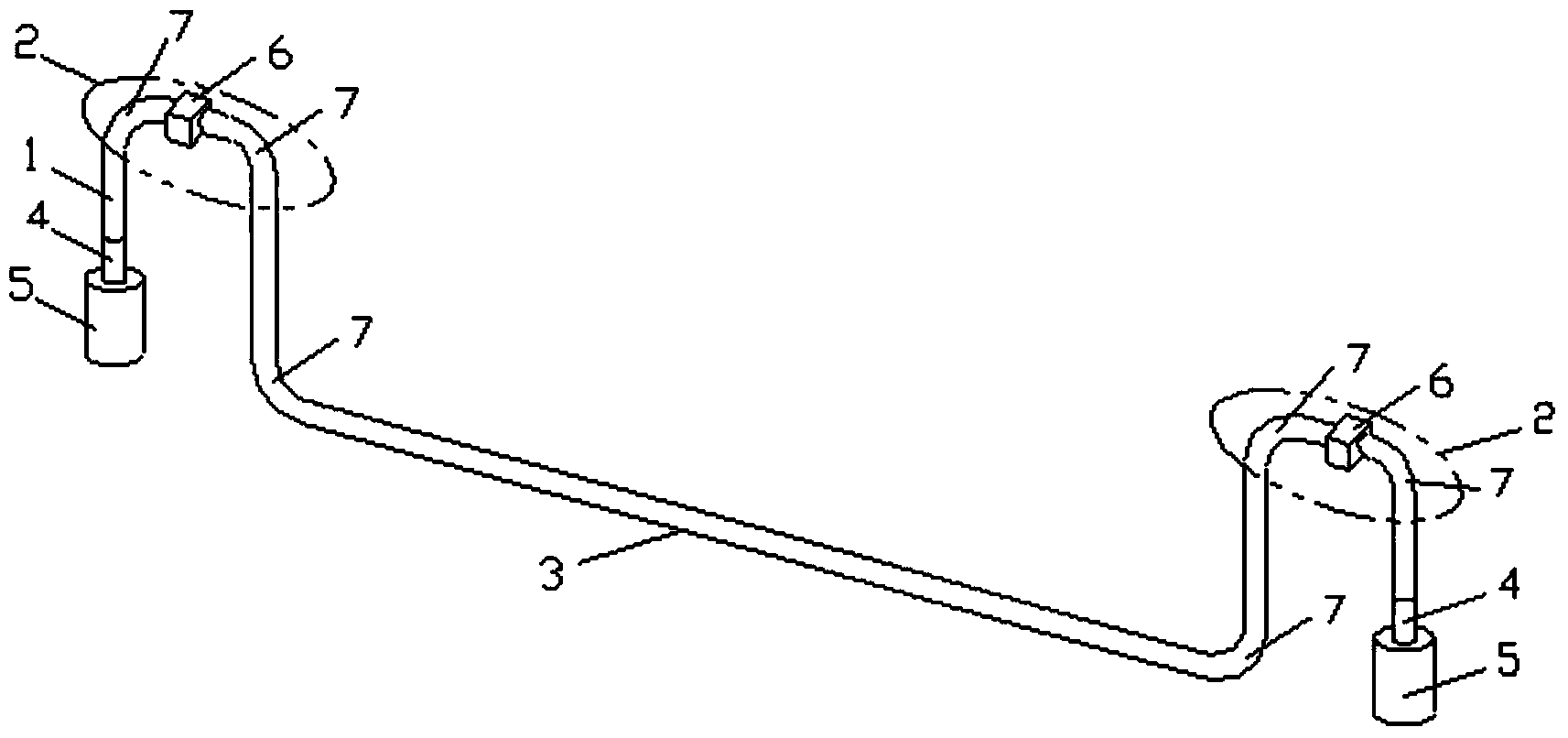

[0012] Such as figure 1 Shown, the present invention is provided with a pipeline 1, and this pipeline is The shape includes: a Π-shaped pipe section 2 arranged at both ends, an inverted Π-shaped pipe section 3 arranged in the middle, wherein the ends of the Π-shaped pipe section 2 at both ends are installed with a sleeve 4 for connecting with the submarine pipeline, A connector 5 for connecting the underwater pipeline to the wellhead or terminal is installed on the sleeve 4 , and the vertical part of the pipeline and the horizontal connection part are connected by an elbow 7 .

[0013] Above-mentioned pipeline 1 installs the operation panel 6 of ROV.

[0014] When in use, the present invention is lowered through the ship crane or winch installed on the sea, and installed on the underwater base plate and the wellhead or the pipeline terminal to connect the oil and gas resource transmission pipeline, and utilize the flexibility and structural strength of the structure itself t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com