Deformable nail frame for carpet forming die

A molding die and nail frame technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of increasing the size of carpet waste, unfavorable automated production, and increased carpet costs, and achieves a simple structure, satisfying The need for automation, the effect of reducing carpet costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

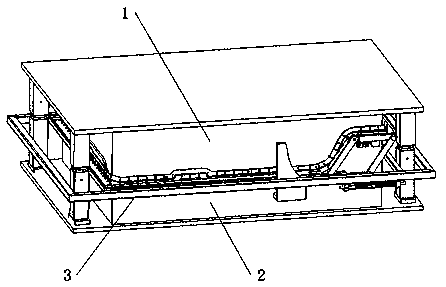

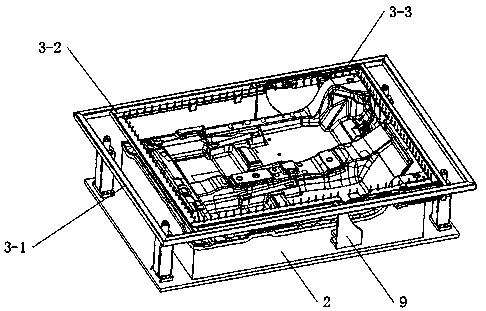

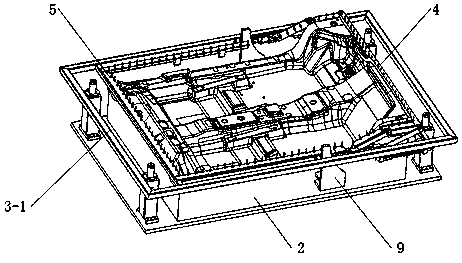

[0019] Such as Figure 1-7 As shown, a carpet forming mold deforms a nail frame. The carpet forming mold includes an upper mold 1 and a lower mold 2. The nail frame 3 is nailed with a face blanket, and the nail frame 3 is placed between the upper mold 1 and the lower mold 2. During mold closing, the nail frame 3 is pressed down by the upper mold 1, and the nail frame 3 and the lower mold 1 move relatively; the nail frame 3 includes an outer frame 3-1, an inner frame 3-2, and the inner frame 3-2 is set Inside the outer frame 3-1, several pegs 3-1 are evenly distributed on it, and the blanket is nailed on the nail frame 3 through the pegs 3-3; the inner frame 3-2 is divided into two halves, wherein One half is the deformed inner frame 4, and the other half is the fixed inner frame 5; the deformed inner frame 4 and the fixed inner frame 5 are both composed of two transverse side bars and a longitudinal side bar; the transverse side bars constituting the deformed inner frame 4 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com