Patents

Literature

100results about How to "Meet the needs of automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

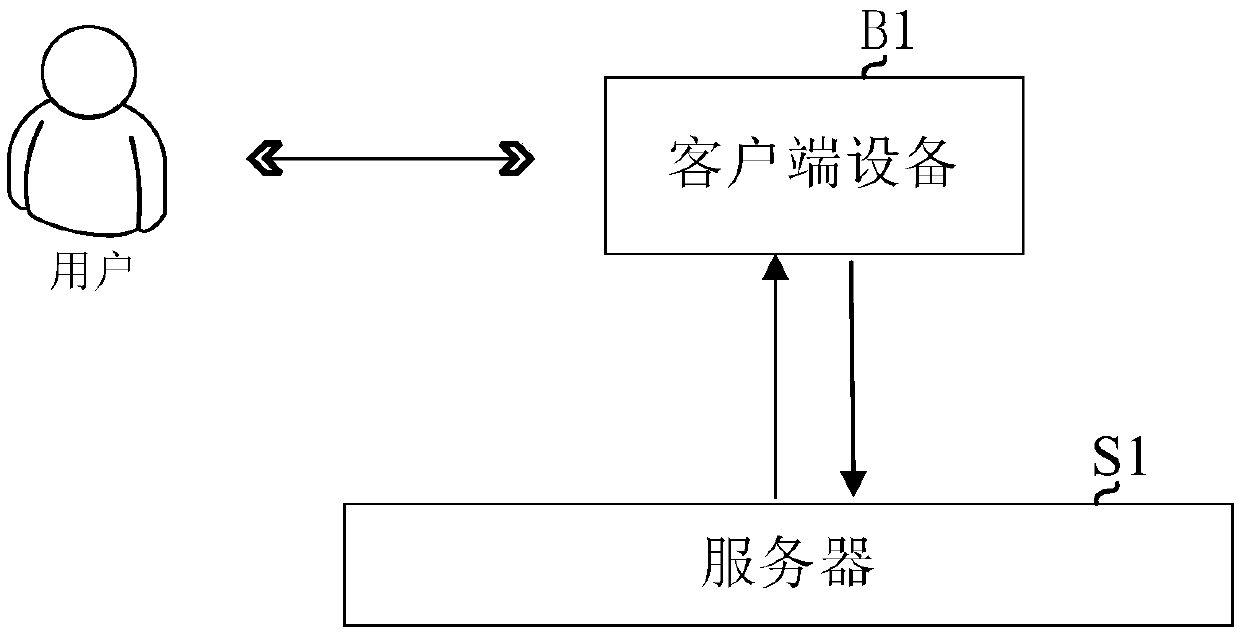

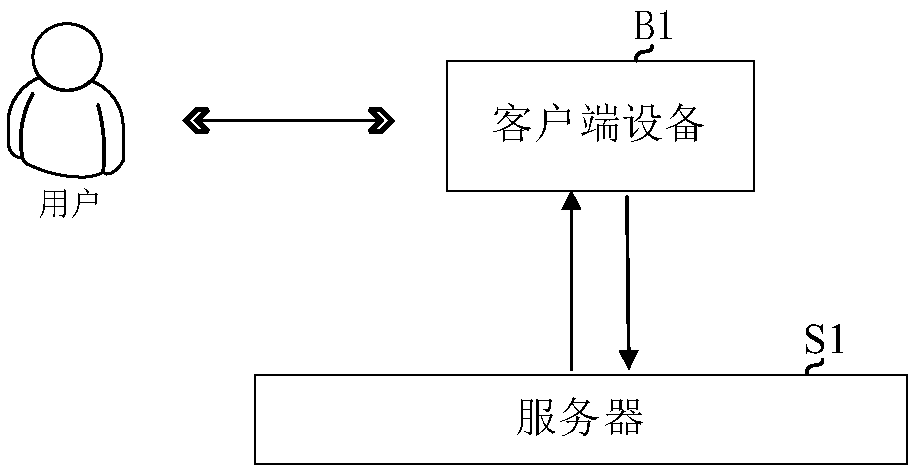

Method for automatically configuring distributed system, and server

InactiveCN102455915AFully functionalMeeting Automation NeedsProgram loading/initiatingBootingMetadata

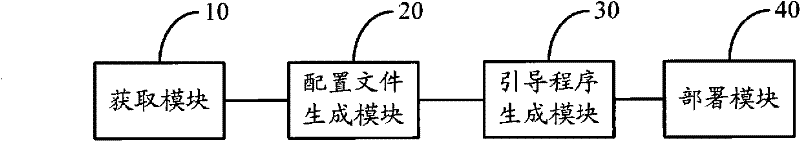

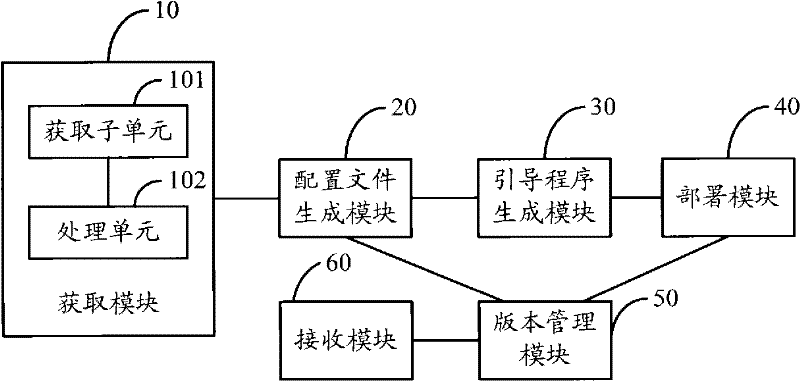

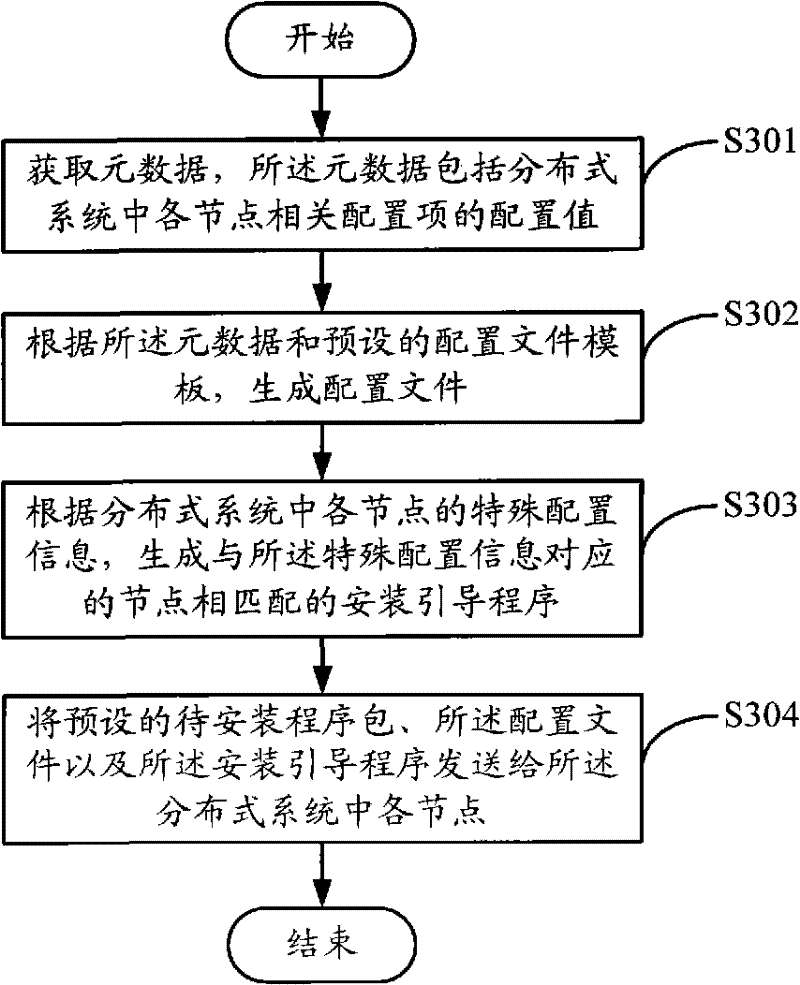

The embodiment of the invention discloses a method for automatically configuring a distributed system. The method comprises the following steps of: acquiring metadata which comprises the configuration information of each node in the distributed system; according to the metadata and a preset configuration file template, generating a configuration file; according to the special configuration information of each node in the distributed system, generating an installation boot program which is matched with a node corresponding to the special configuration information; and sending a preset program package to be installed, the configuration file and the installation boot program to each node in the distributed system. The embodiment of the invention also discloses a server. By the invention, the problems of high working load and high error rate caused by installation or modification of the programs of all nodes in the distributed system when the programs of a client are required to be installed or modified can be solved, and functions of each node in the distributed system can be fully realized by installing the programs according to the special configuration information of each node in the distributed system.

Owner:卓望数码技术(深圳)有限公司

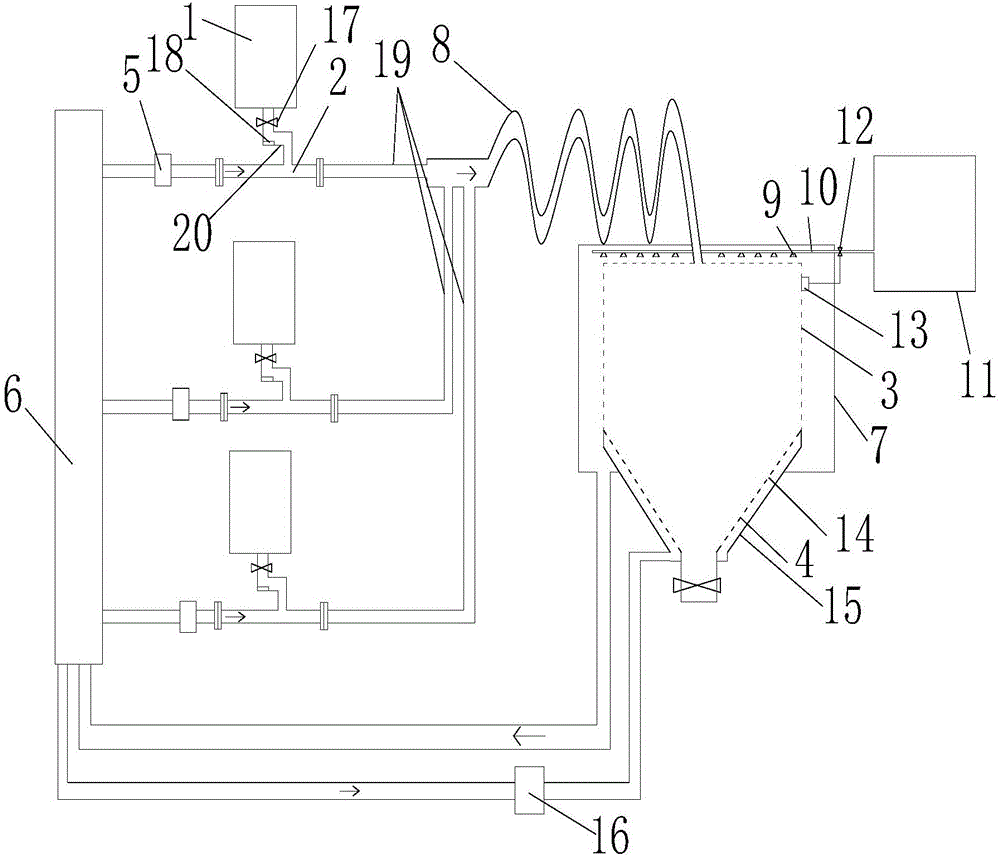

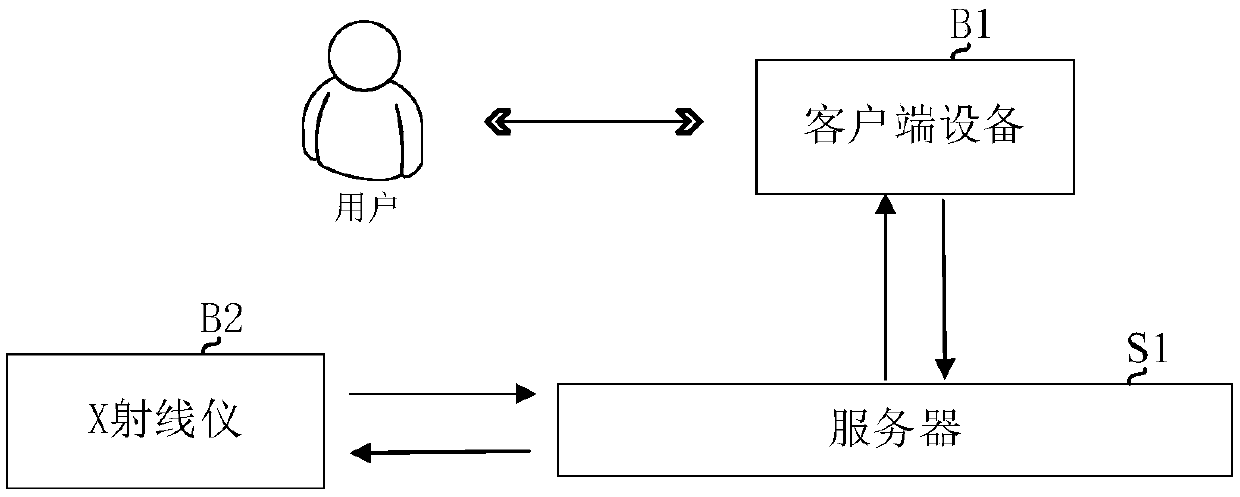

Control method and system for coke oven riser pipe

InactiveCN106753444ARealize safety interlockImprove working accuracyCoke oven safety devicesDistillation gas withdrawalTime deviationAutomatic control

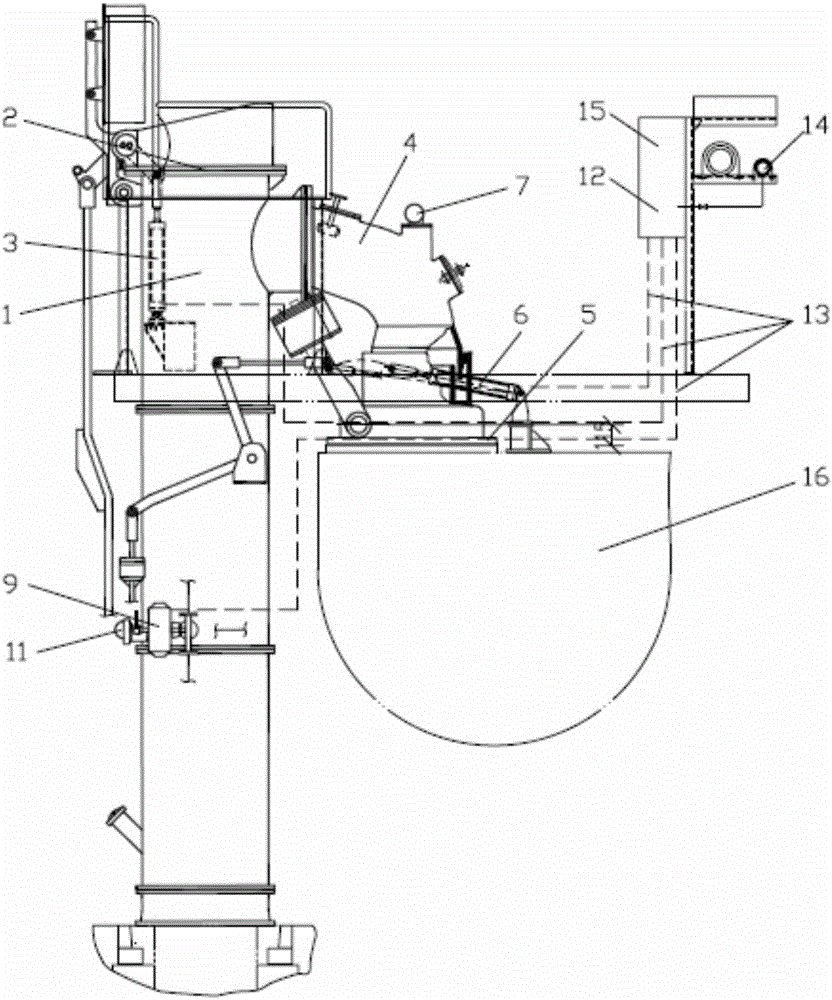

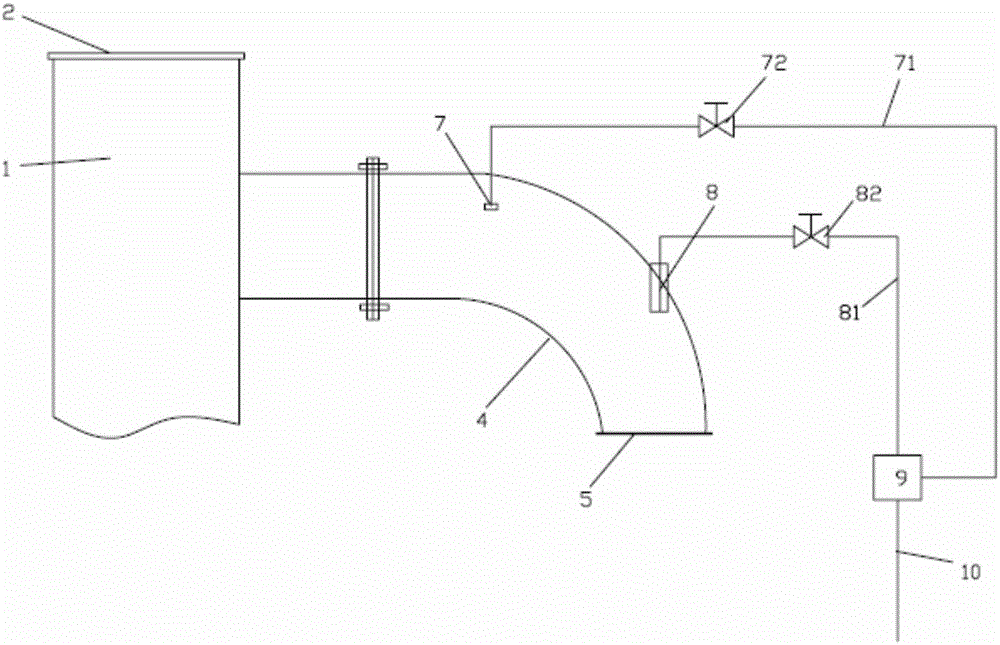

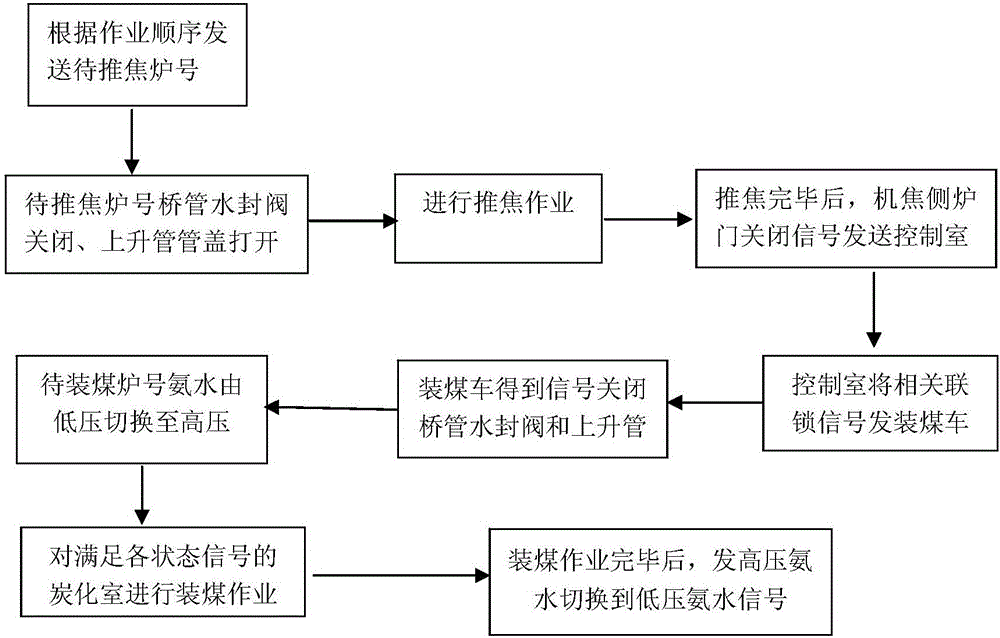

The invention discloses a control method and system for a coke oven riser pipe. The system comprises the riser pipe, a bridge pipe, a low pressure ammonia water spray nozzle, a high pressure ammonia water spray nozzle, a corresponding low pressure ammonia water pipeline, a corresponding high pressure ammonia water pipeline and a programmable controller, wherein a pipe cover capable of being opened and closed and a pipe cover driving cylinder are arranged on the riser pipe; the bridge pipe is connected to an end opening in one side of the riser pipe; a water seal valve and a water seal valve driving cylinder are arranged at the lower end of the bridge pipe; the low pressure ammonia water spray nozzle is arranged at a position, which is close to a riser pipe joint, in the bridge pipe; the high pressure ammonia water spray nozzle is arranged at a position, which is located below the low pressure ammonia water spray nozzle, in the bridge pipe; the low pressure ammonia water pipeline and the high pressure ammonia water pipeline are respectively connected to two end openings of a three-way ball valve; the three-way ball valve is connected with a three-way ball valve driving cylinder or an electromagnetic driving valve; an electromagnetic switching valve or / and the electromagnetic driving valve is / are electrically connected with the controller, and is / are electrically connected with a coke oven control system. According to the control system disclosed by the invention, safe interlocking between all facilities of the riser pipe and work of a coal charging car of the coke oven and a coke pusher is realized; by automatic control and replacement of unmanned work for manual work, the cooperation order of workers and the time deviation of the manual work are eliminated, and the safety and environmental protection risk during work of the coke oven riser pipe is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

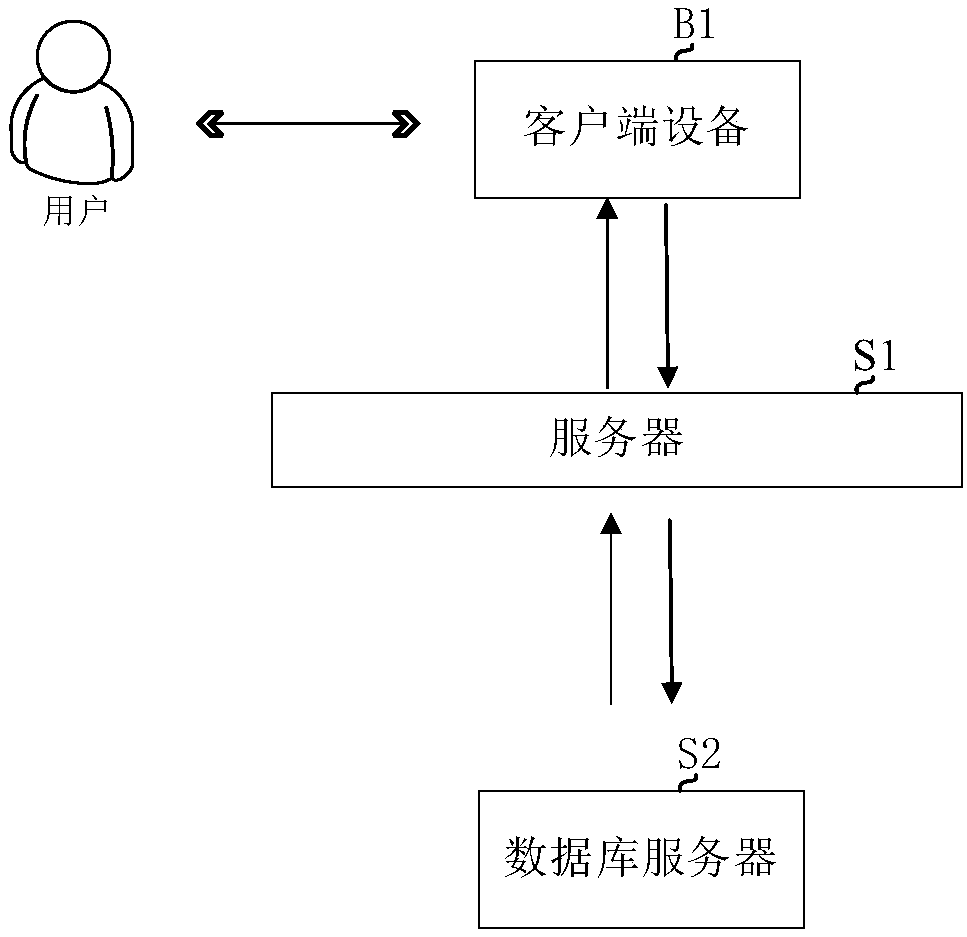

Printing production control and early-warning system

InactiveCN104240406AMeeting Automation NeedsAvoid defectsComplete banking machinesDelivery timingData preservation

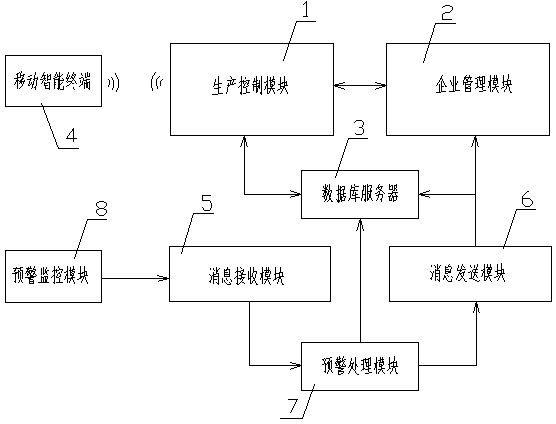

The invention discloses a printing production control and early-warning system. The data of a production control module and an enterprise management module of the system are synchronized in real time. A mobile intelligent terminal is used for acquiring workload and progress information in real time, and transmitting the information to the production control module through a wireless network. The production control module is used for storing the data, and performing information sharing through a database server. An early-warning monitoring module is used for monitoring a production process, and transmitting information to a message receiving module in real time. An early-warning processing module is used for receiving and transmitting early-warning information, monitoring production progresses of all order, comparing current production time with predicted order delivery time in real time, and transmitting the early-warning information to the enterprise management module in case of delay. The enterprise management module is used for changing and regulating a production plan. The mobile intelligent terminal and the production control module are used for implementing the production plan according to a changed production instruction. According to the system, each link of a printing production flow is controlled and early-warned to realize accurate control and real-time alarming, and the production management requirements of an enterprise are met.

Owner:上海技亨信息科技有限公司

Configurable industrial bus interface supporting protocol

InactiveCN102789210AImprove compatibilityIncrease flexibilityTotal factory controlProgramme total factory controlFpga implementationsMaster station

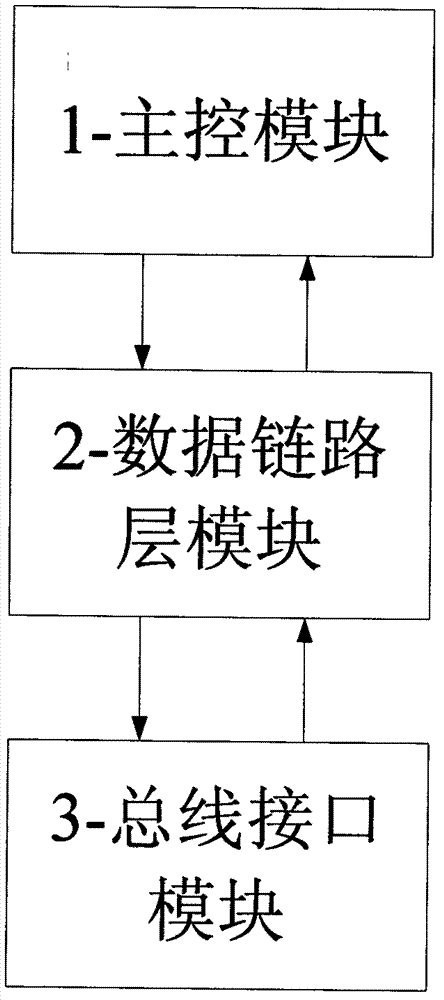

The invention relates to a configurable industrial bus interface supporting protocols. A main control module is realized based on control of a CPU, the main control module operates according to a user configuration mode, and the main control module realizes application layer logic of protocol specifications. A data link layer module is realized based on FPGA which can be programmed to configure and operates in a hardware mode. The data link layer module can be flexibly configured to be a data link layer of a master station or slave stations with a ProfiBus specification, and also can be configured to be a data link layer of a master station or slave stations with a ModeBus specification. The industrial bus interface makes instruments be advantaged by good compatibility, high flexibility, low cost, fast speed, high automation degree, good security, and convenient field application.

Owner:SHANGHAI HUAJIAN ELECTRICAL EQUIP

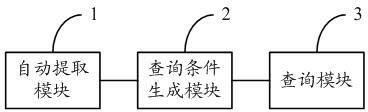

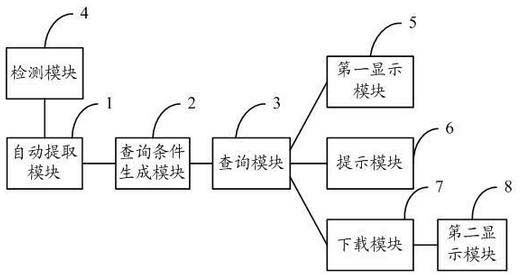

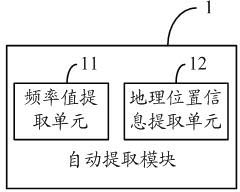

Method for inquiring program play messages and mobile terminal

InactiveCN102111676AMeeting Automation NeedsMeet the needs of automationSelective content distributionSpecial data processing applicationsComputer terminalBroadcasting

The embodiment of the invention discloses a method for inquiring program play messages, comprising the following steps: extracting channel identifying information on a program which is played currently; and generating inquiring conditions in accordance with the channel identifying information and preset inquiring type information, and inquiring program play information of the channel corresponding to the program which is played currently in accordance with the inquiring conditions. Accordingly, the embodiment of the invention also provides a mobile terminal. By using the method and the mobile terminal, related key words which are used for inquiring the program play information can be automatically extracted so as to accurately inquire the program play information, and then an inquiring result can be provided for a user, thus simply and conveniently realizing a program parade function and the like. The user can reasonably schedule to watch television programs at the mobile terminal or programs at a broadcasting station, thereby being convenient for the user and meeting automation demands of the user.

Owner:DONGGUAN YULONG COMM TECH +1

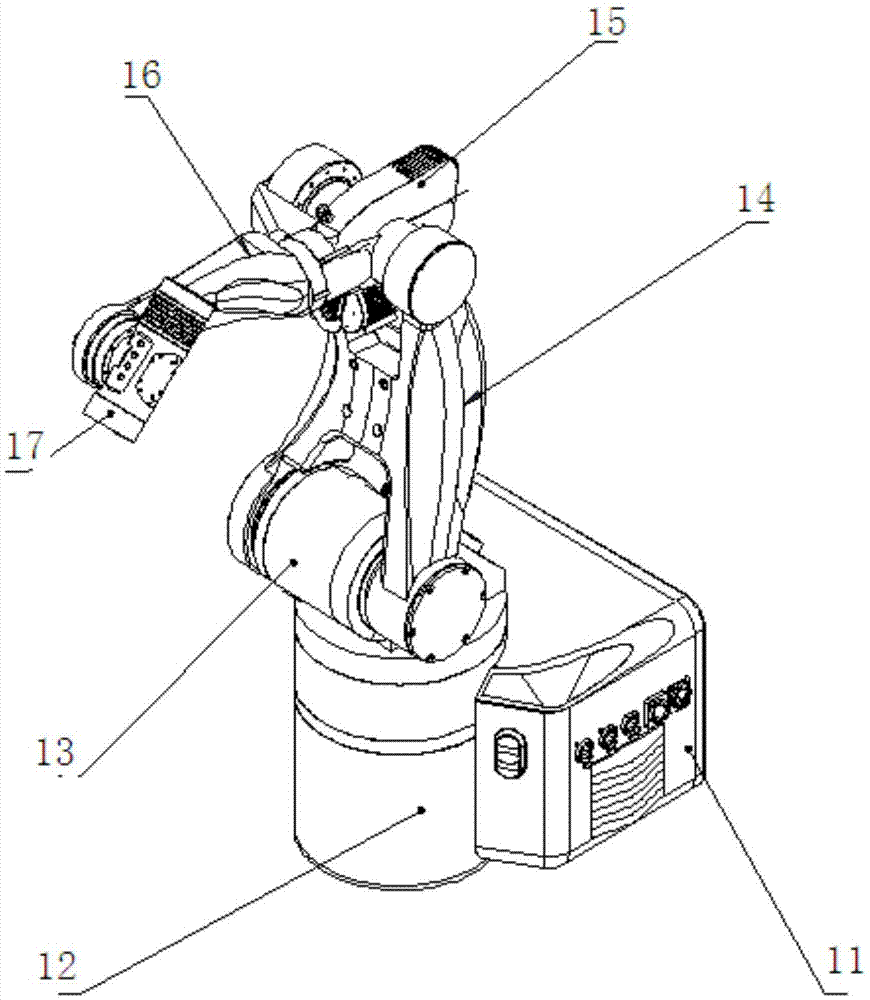

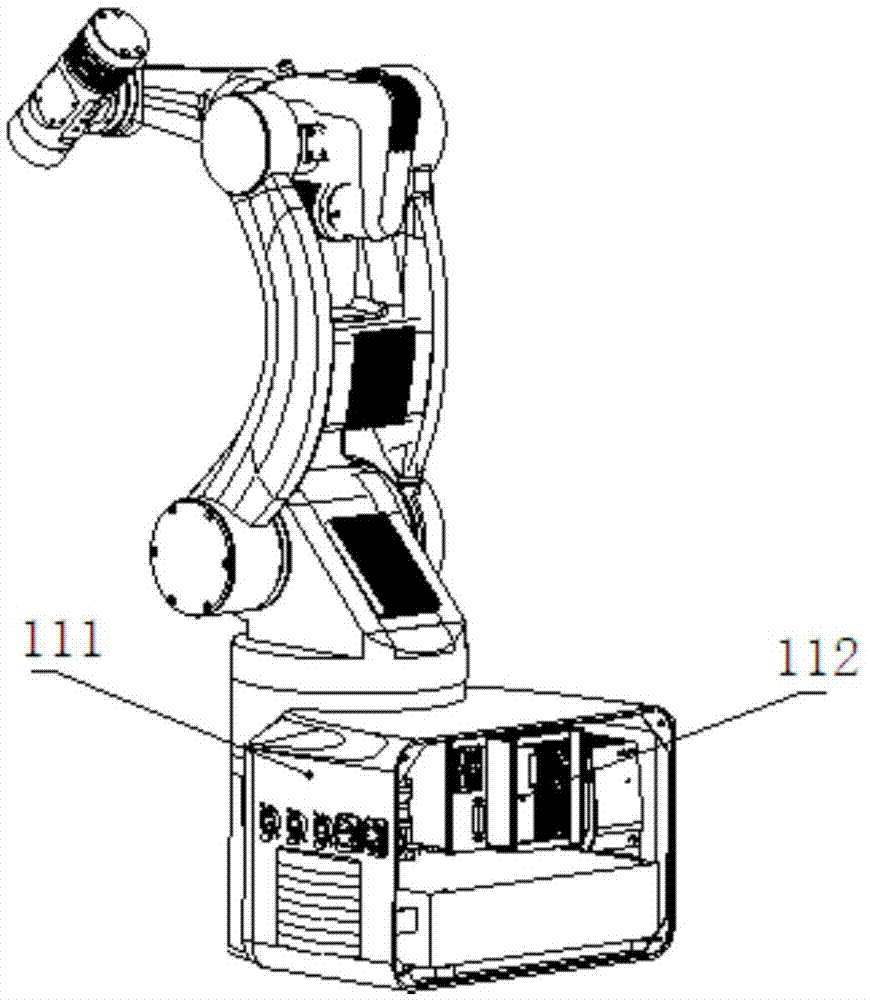

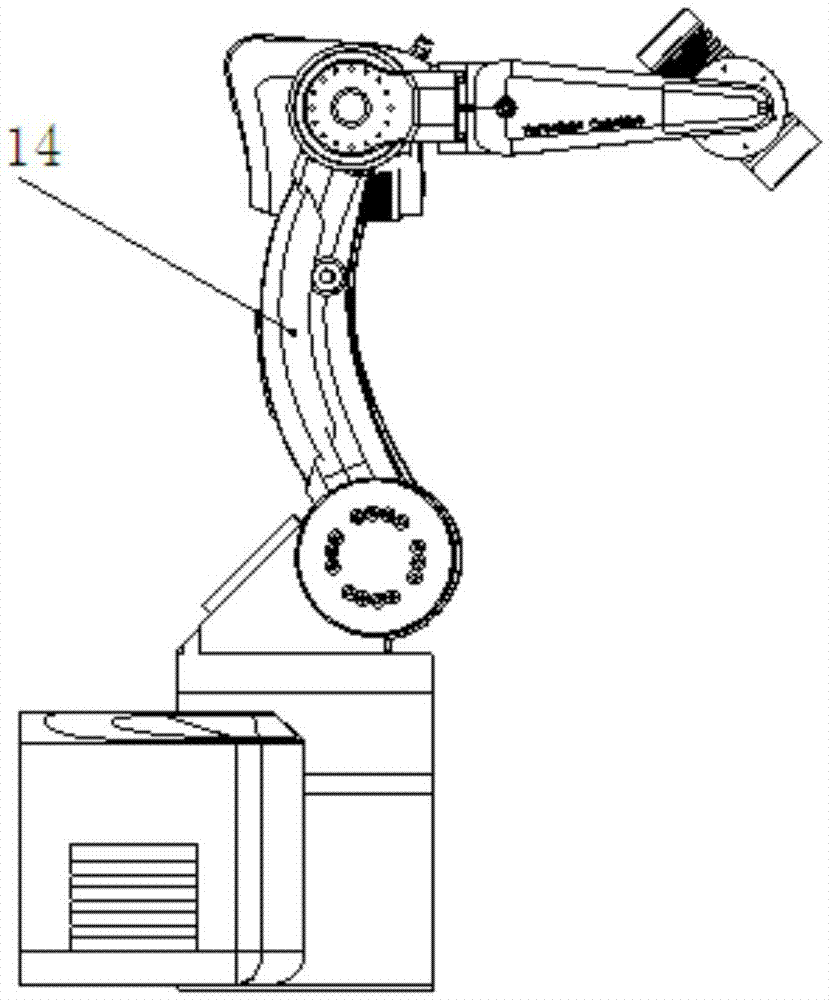

Desk type high-speed high-precision robot

PendingCN107186694AHigh load-to-weight ratioCompact structureProgramme-controlled manipulatorElbow blockControl engineering

The invention provides a desk type high-speed high-precision robot comprising an integrated control cabinet, a base body, a rotary seat, a large arm, an elbow joint seat, a small arm and a wrist body. The integrated control cabinet comprises a control cabinet box and a drive-control integrated controller. The base body and the integrated control cabinet are integrated. The rotary seat is arranged on the base body and is used for achieving rotation of the robot in the horizontal direction. The bottom end of the large arm is arranged on the rotary seat and is used for rotating around a joint connected with the rotary seat. The elbow joint seat is arranged at the top end of the large arm. One end of the small arm is connected to the elbow joint seat. The wrist body is connected to the other end of the small arm. The desk type high-speed high-precision robot has the advantages of being high in load ratio, compact in structure, and high in speed, precision and flexibility and the like, and the requirements of automation operation of 3G and other industries can be met.

Owner:AGILEBOT ROBOTICS CO LTD

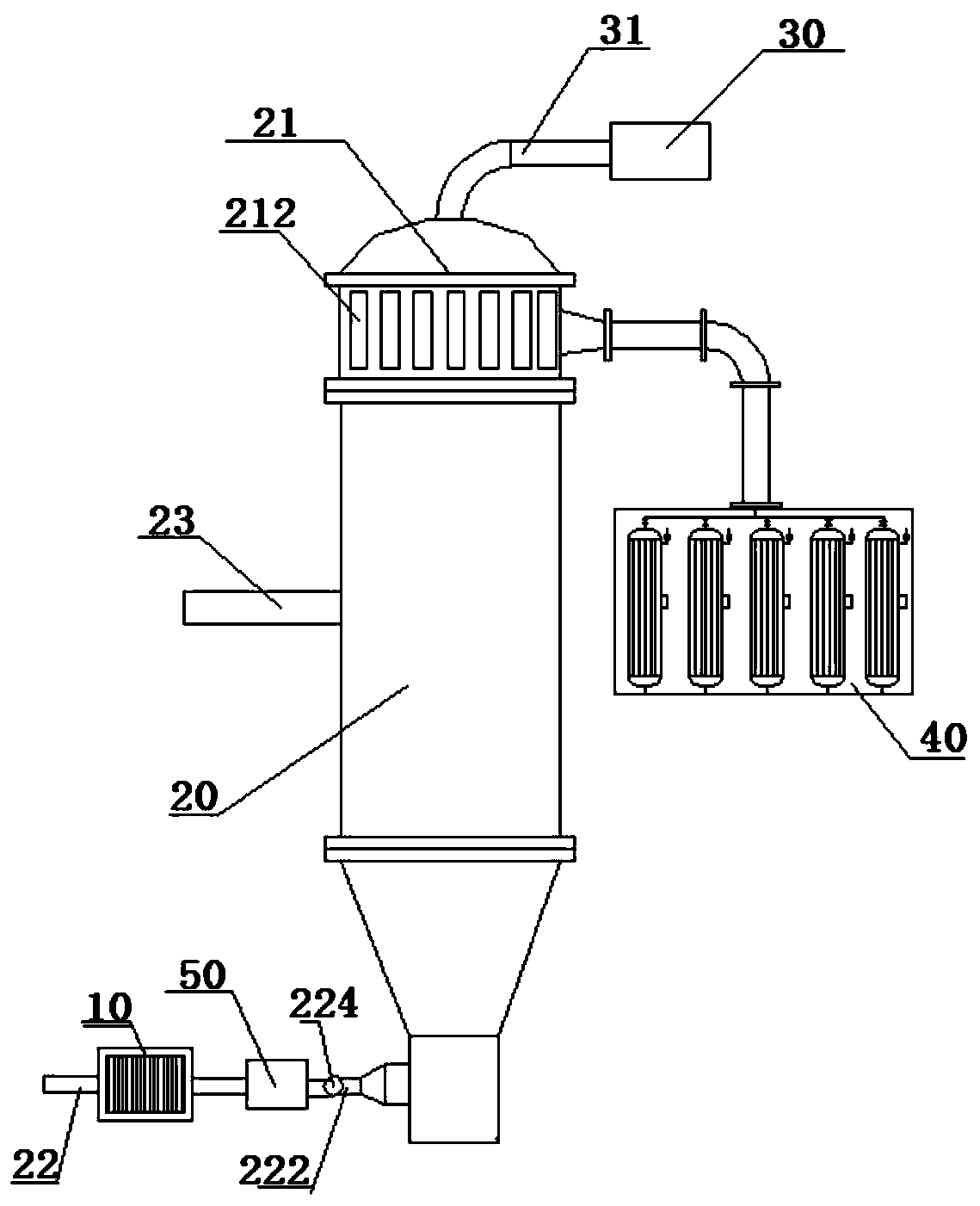

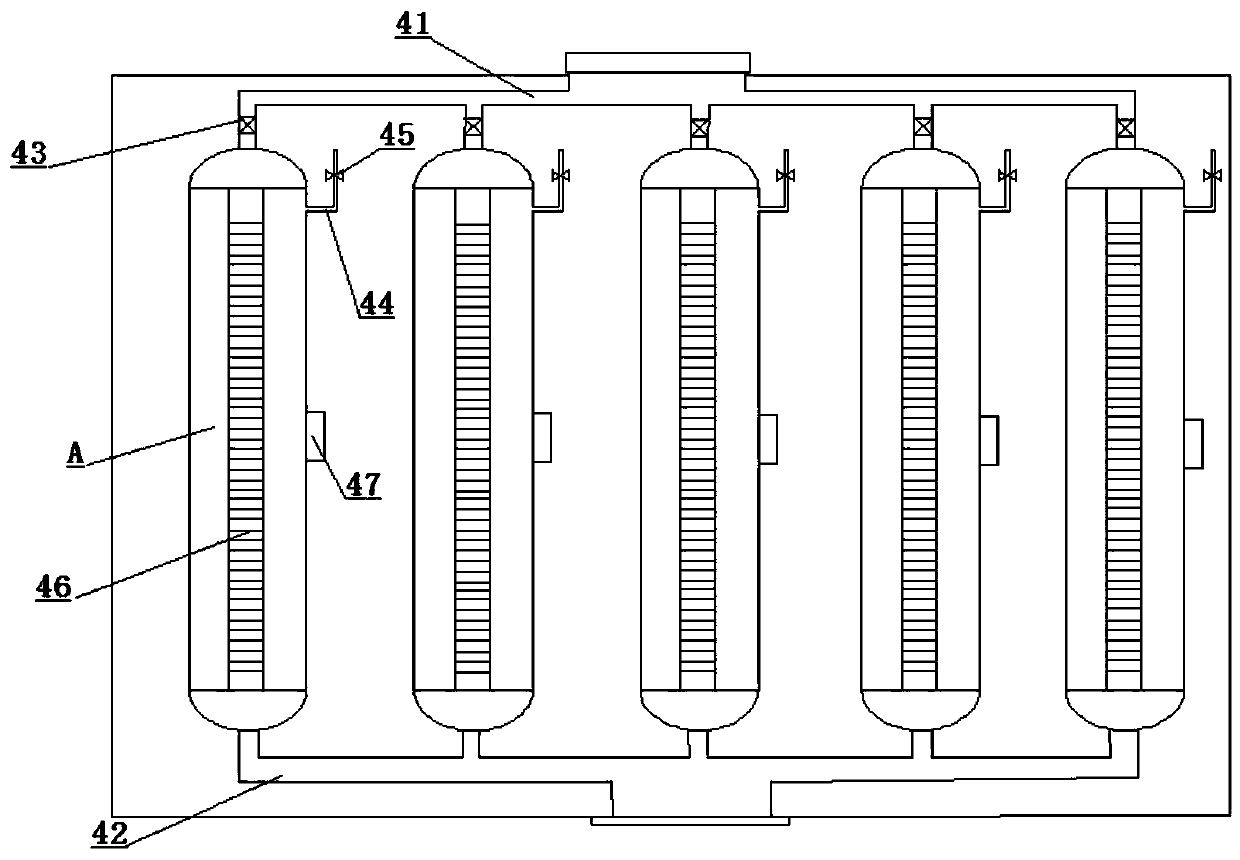

Granulating equipment for preparing hydrotalcite chewable tablets and production process of hydrotalcite chewable tablets

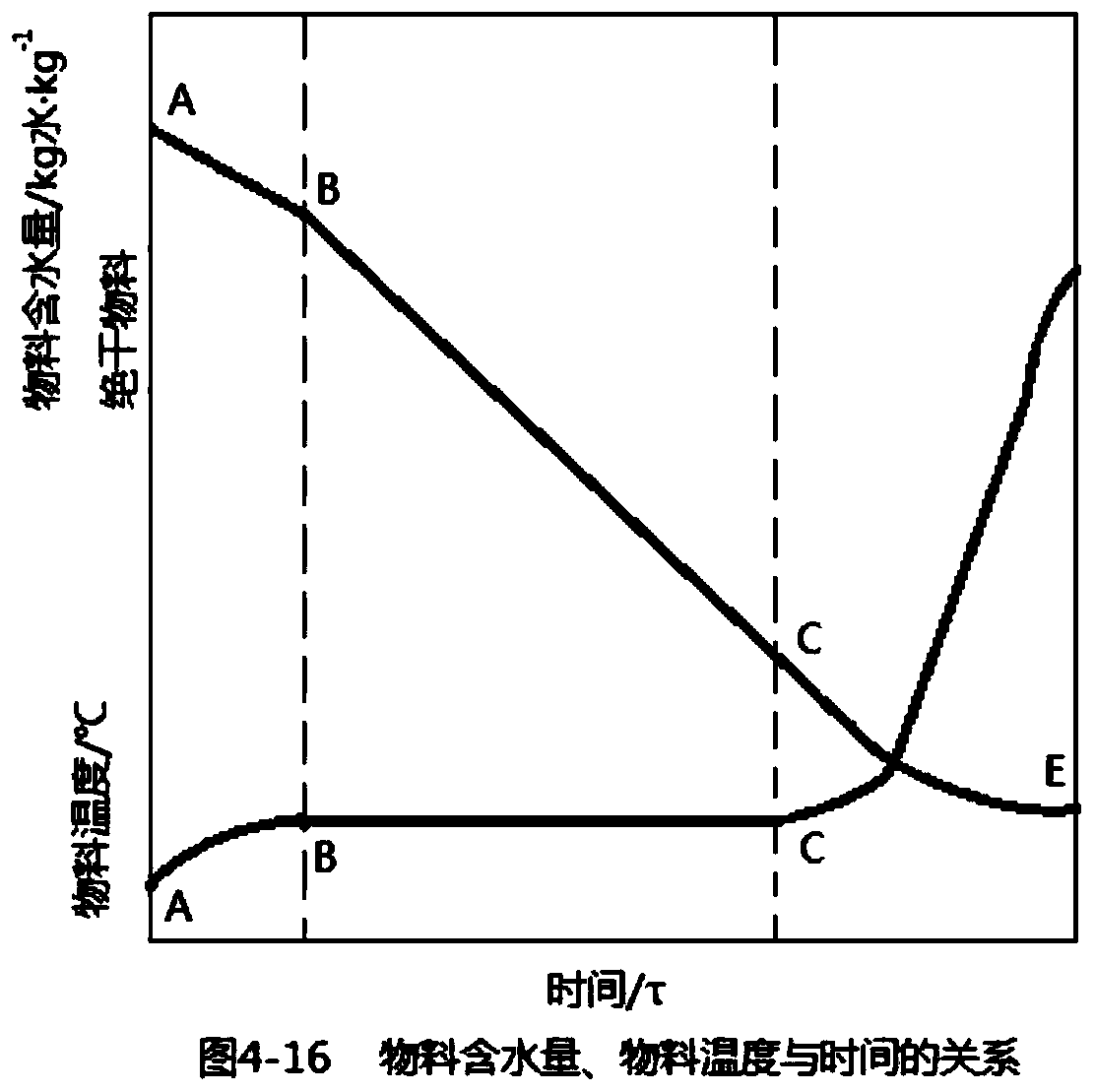

ActiveCN110131965ALow costAccurate detectionDrying solid materials with heatMaterial analysis by observing effect on chemical indicatorModern medicineBiochemical engineering

The invention discloses an ebullated dryer for preparing hydrotalcite chewable tablets and a production process of hydrotalcite chewable tablets. The production process of the hydrotalcite chewable tablets comprises the following steps of weighing, mixing, wet granulation, drying and tabletting. The production process of the hydrotalcite chewable tablets is simple and convenient, and has simple operation. The ebullated dryer for preparing the hydrotalcite chewable tablets has the function of automatically controlling a drying endpoint, is simple in device, low in cost, accurate in detection and high in automation degree, and meets the requirement of modern drug production on automation.

Owner:TEYI PHARMACEUTICAL GROUP CO LTD

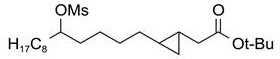

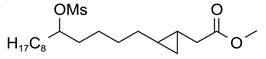

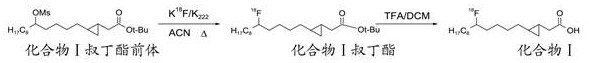

Preparation method and application of myocardial metabolism PET imaging agent

PendingCN114736112AIncreased radioactivityHigh labeling rateOrganic compound preparationCarboxylic acid esters preparationAcetic acidTridecane

The invention provides a preparation method and application of a myocardial metabolism PET imaging agent trans-2-(2-(5-(fluorine [18F]) tridecyl) cyclopropyl) acetic acid (a compound I for short). Comprising the following steps: a nucleophilic substitution reaction: mixing activated < 18 > F ions with a solution containing a compound I tert-butyl ester precursor, and carrying out the nucleophilic substitution reaction to obtain an intermediate product solution containing the compound I tert-butyl ester; and a tert-butyl ester group removal reaction: adding an acidic solvent into the intermediate product solution of the tert-butyl ester of the compound I, and carrying out the tert-butyl ester group removal reaction to obtain a product containing the compound I. The yield and the labeling rate are improved, and the radiochemical purity is high.

Owner:BEIJING SINOTAU INT PHARMA TECH CO LTD

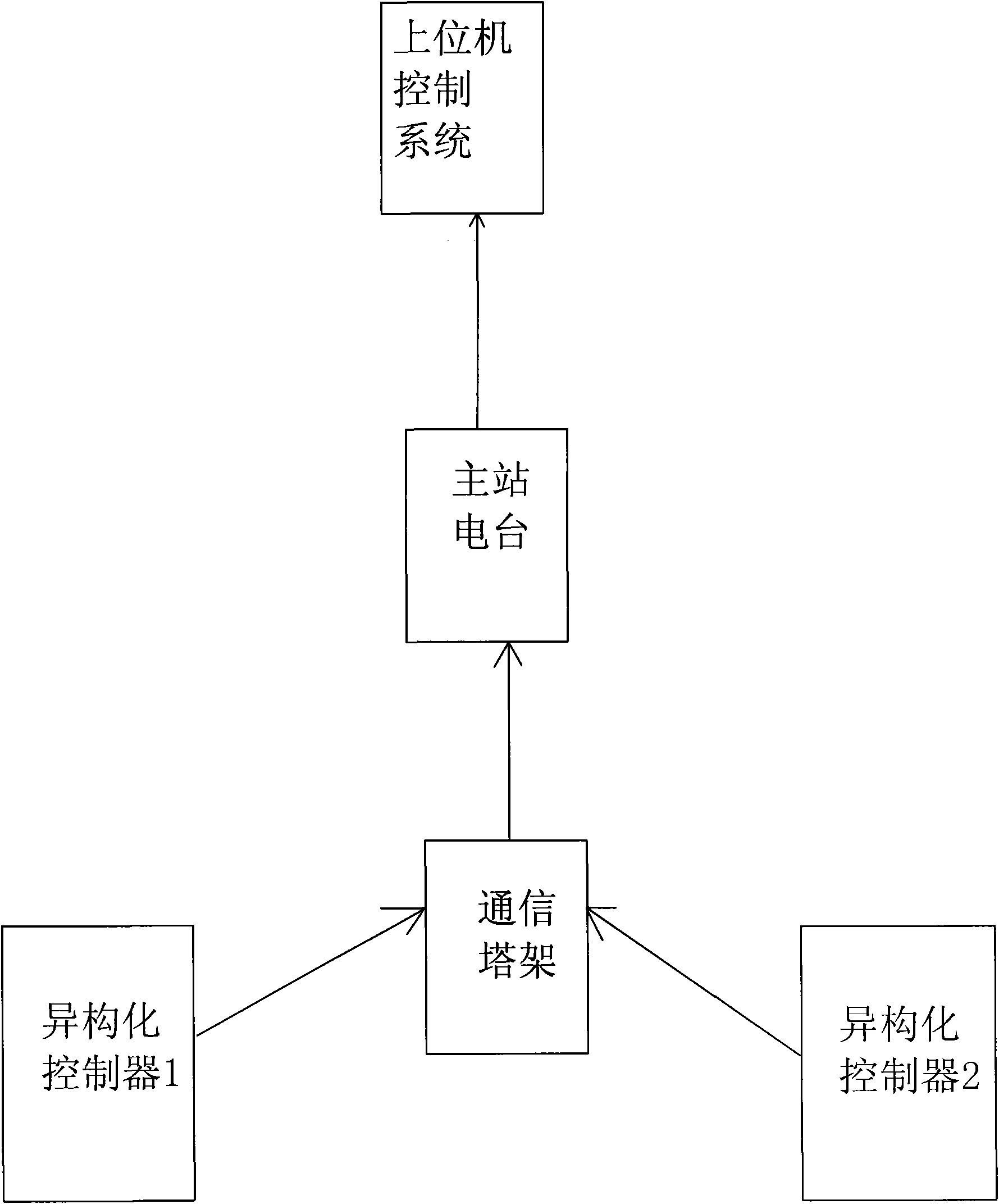

Automatic control system accessed to automatic heteroid controller and application thereof

InactiveCN101592940ALow construction costMeet industrial automationTransmissionTotal factory controlModbusAutomatic control

The invention relates to an automatic control system accessed to an automatic isomerous controller. The automatic control system is characterized by comprising an isomerous controller terminal and a central control room, wherein the isomerous controller terminal is provided with a client driver based on an OPC agreement, a communication channel is arranged between the isomerous controller terminal and the central control room, the isomerous controller terminal is provided with an interface which is connected with the communication channel, the data communication of the isomerous controller terminal and the central control room is carried out as an Modbus agreement which is Modbus agreement expansion, and 16 bit device addresses are arranged in the Modbus agreement. The system solves the problem of insufficient quantity of the device addresses in the same Modbus communication network and realizes that isomerous controllers supplied by different manufacturers carry out data communication with the central control room by the same communication channel. The invention also relates to the application of the automatic control system in oilfield automation.

Owner:张建华 +2

Firework gunpowder mixing device

ActiveCN106748586AMeet the needs of automationPrecise continuous production effectExplosive working-up apparatusMulti materialProduction line

The invention discloses a firework gunpowder mixing device which comprises a storage device, a control module, a feeding system and a mixing device, wherein the feeding system is composed of an air amplifier and a conveying pipeline, the storage device communicates with an air-permeable mixing device by the air amplifier of the feeding system and feeds the material to the gas-permeable mixing device, and air holes are formed in the mixing device. The multi-material synchronous, quantity-controllable and continuous material conveying can be realized through the air amplifier, gas mixing is performed so as to achieve continuous gunpowder dispensing, and the precise and continuous production effect of the firework gunpowder that the gunpowder can be dispensed as required can be achieved by the firework gunpowder mixing device and an automatic filling downstream production line, and the safety of the gunpowder mixing process is further guaranteed through the protection gas, the spraying system and the like.

Owner:浏阳市源泰烟花制造有限公司

Incubation chamber and wrapped moving incubation device

InactiveCN101745440AAvoid heat lossGuaranteed stabilityHeating or cooling apparatusEnclosures/chambersThermal insulationElectric heating

The invention relates to an incubation chamber and a wrapped moving incubation device, belonging to the field of full-automatic medical detection instrument. The incubation chamber comprises an incubation disc for holding a reaction cup, an electric heating membrane arranged below the incubation disc, a cover board arranged on the reaction cup and an external insulation layer. The incubation chamber is characterized in that the incubation disc and the cover board are aluminium plates provided with a plurality of long grooves; the incubation disc and the cover board are buckled with each other in a reverse direction so that the grooves can correspond with each other and the edges of the grooves can contact with each other; and the reaction cup is arranged in an incubation channel formed by the two grooves. The temperature of each part of the incubation chamber is similar, thus ensuring stability of the temperature and ensuring detection accuracy. The space of the whole incubation chamber is divided into a plurality of relatively independent incubation channels by the wrapped moving incubation device; reaction cups with different incubation time can be placed in different incubation channels so that the reaction cups can get in and out of the incubation chamber through the inlet and the outlet of a thermal insulation baffle, and the reaction cups on the same incubation channel can be controlled seperately.

Owner:河北质康医疗器械科技有限公司

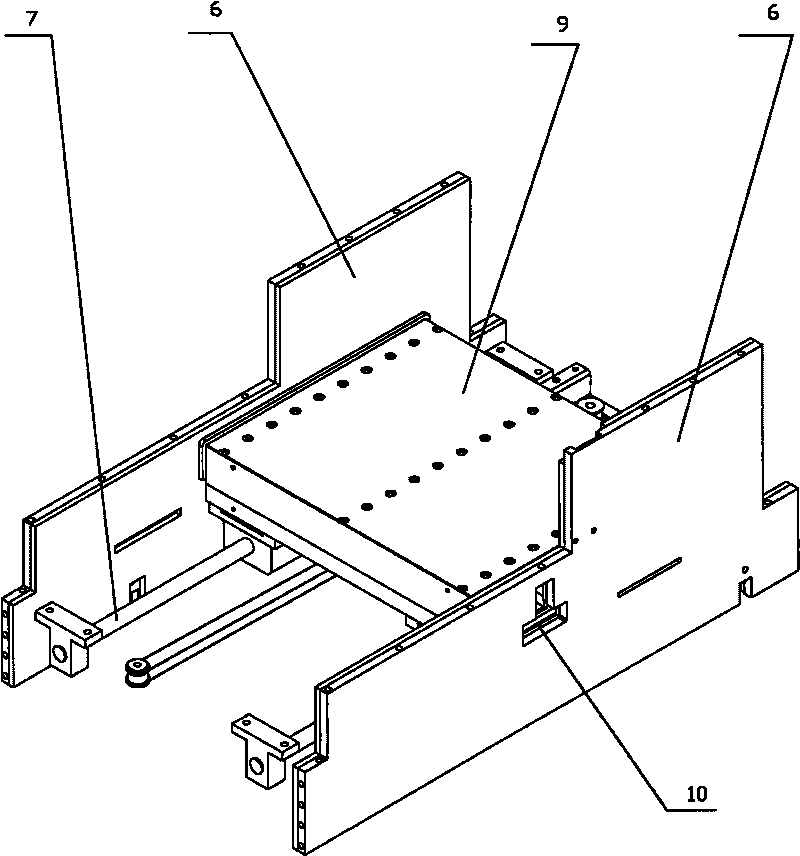

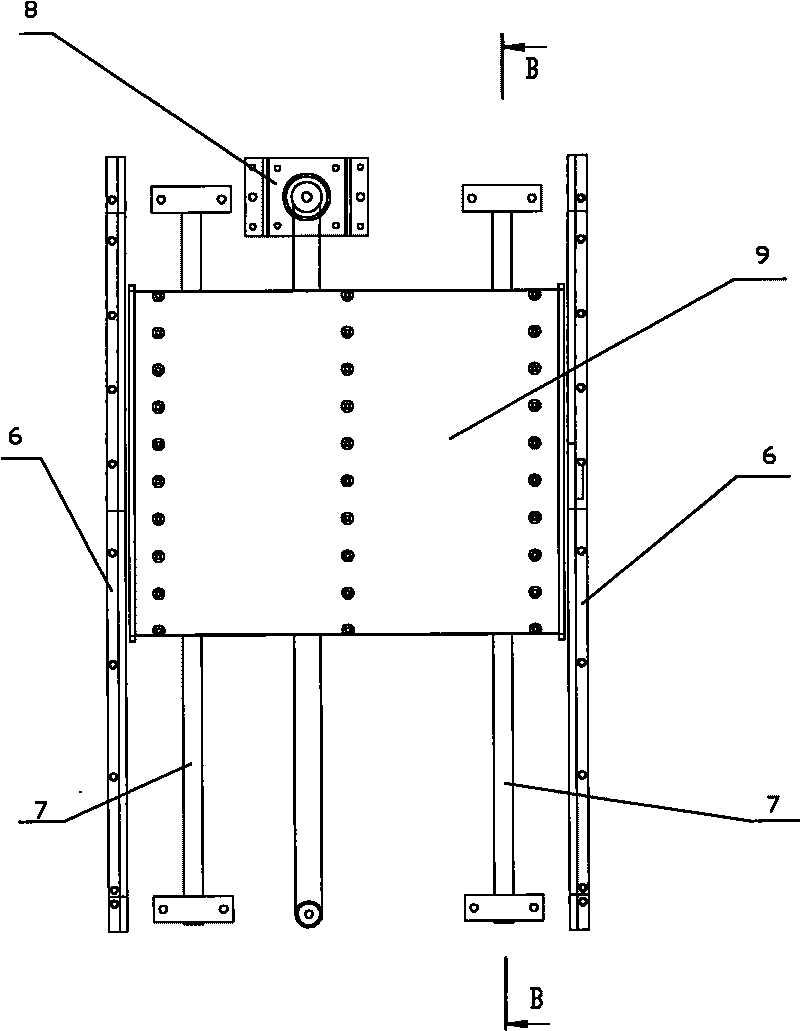

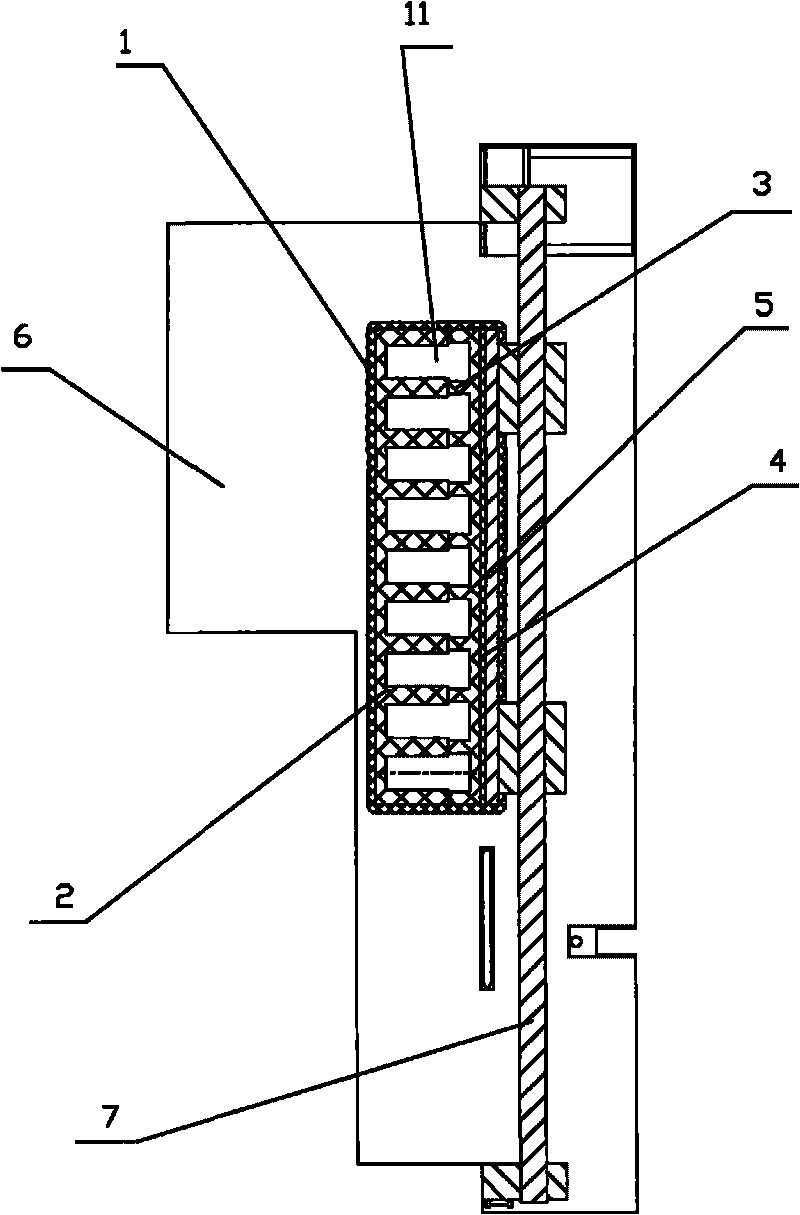

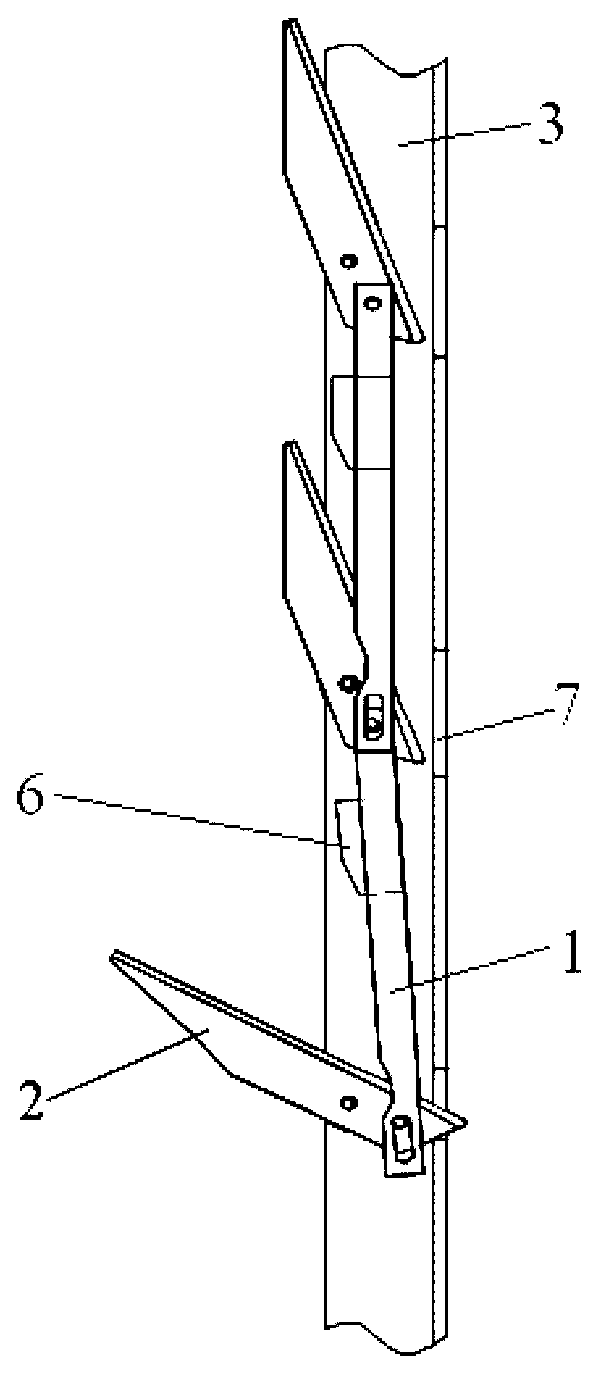

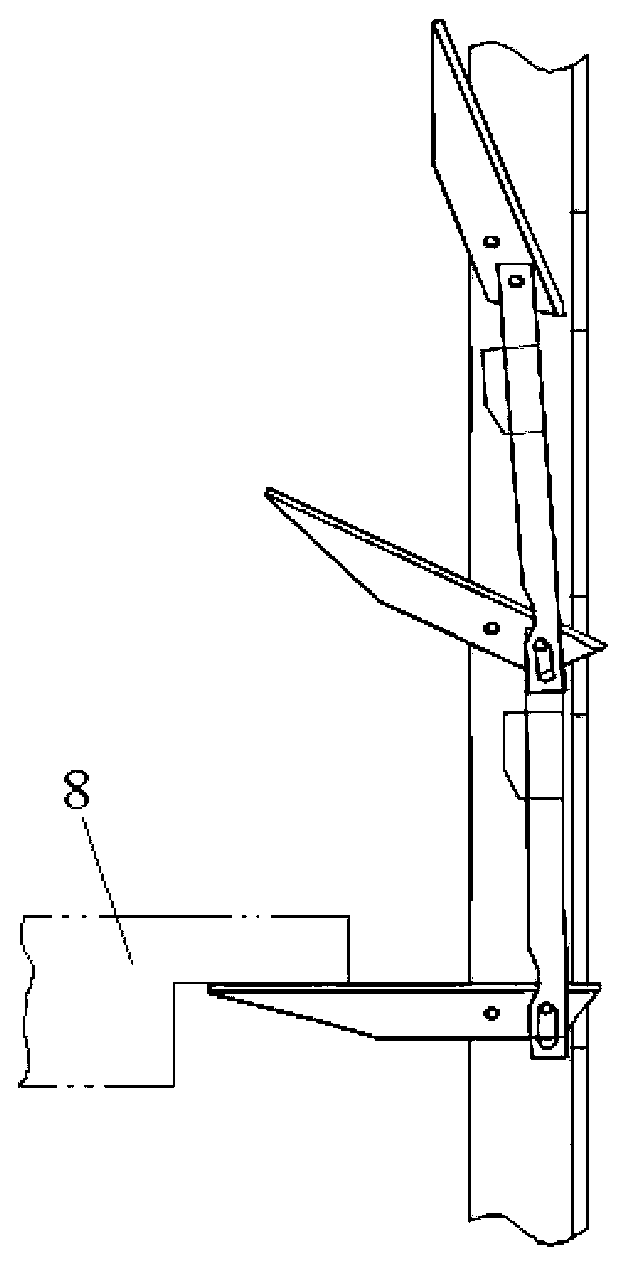

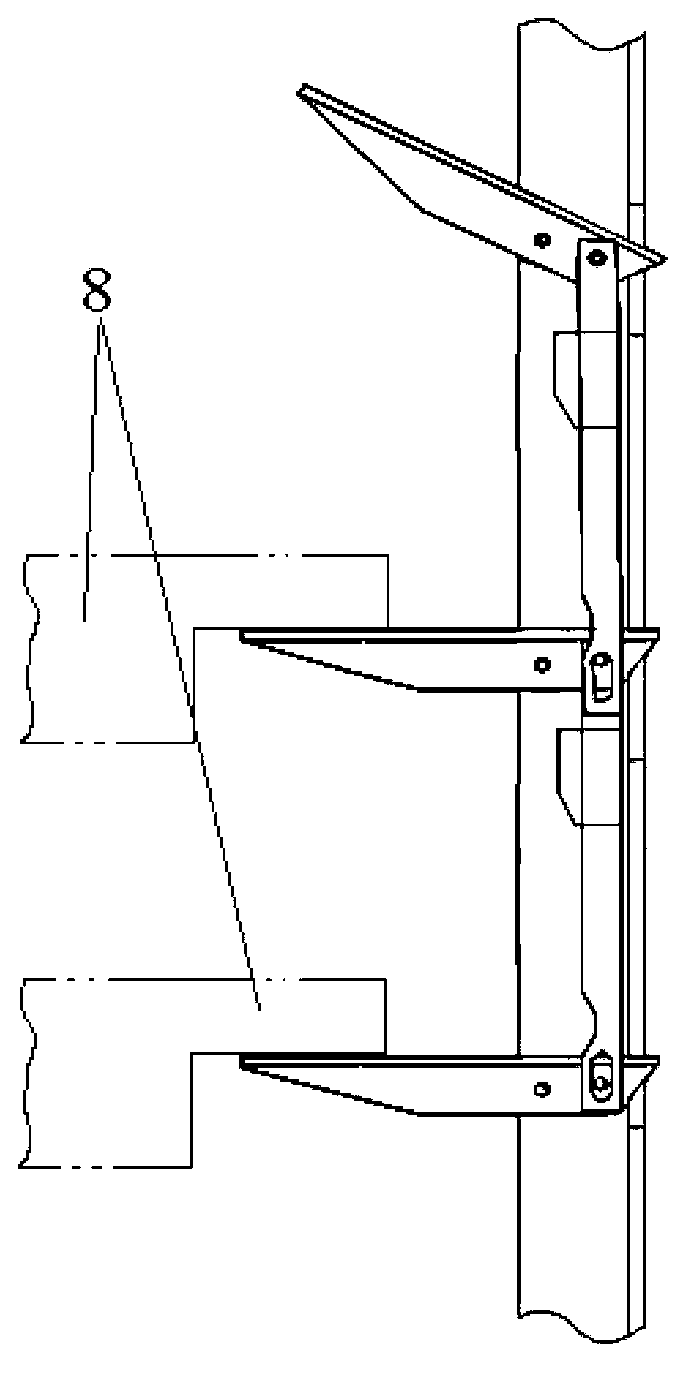

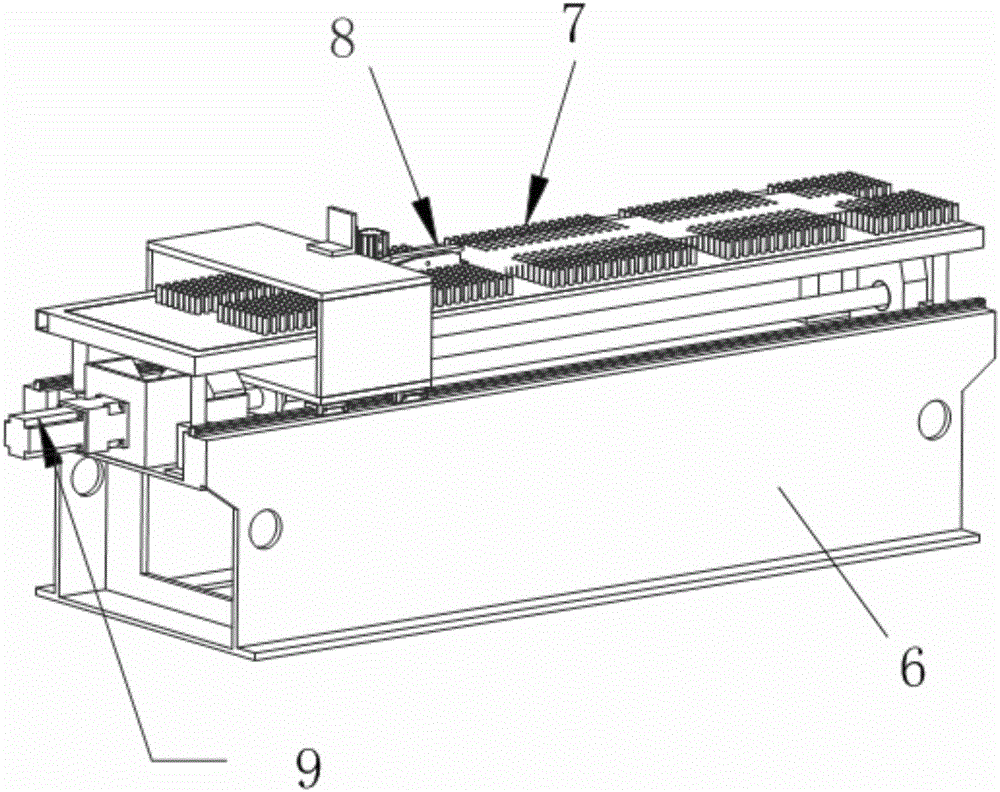

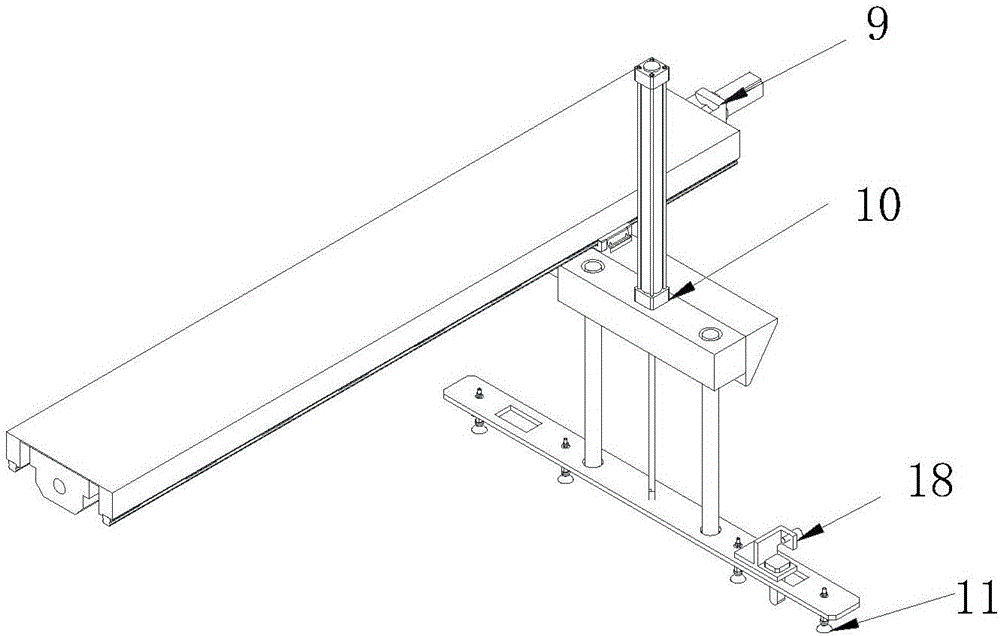

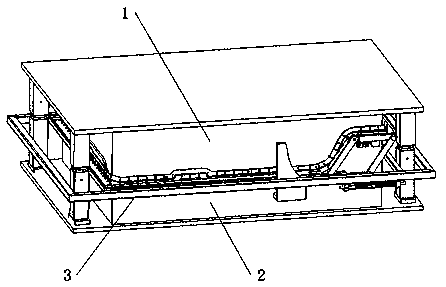

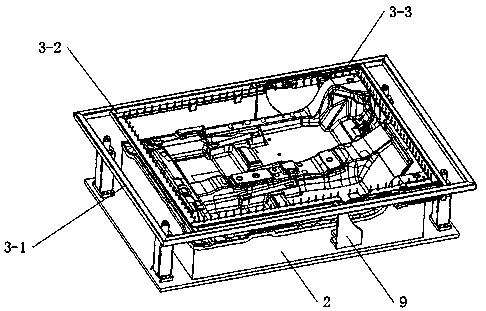

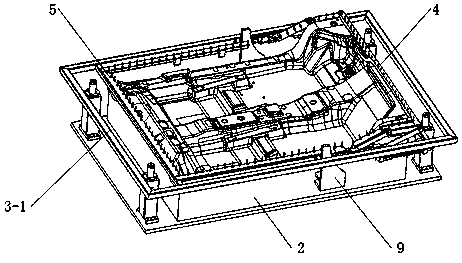

Multi-layer material-storing frame and using method thereof

ActiveCN102744721AHigh degree of automationImprove loading and unloading efficiencyWork tools storageAutomationSupport materials

The invention discloses a multi-layer material-storing frame. The multi-layer material-storing frame comprises supporting discs which are arranged on upper and lower layers and are arranged on upright posts of the multi-layer material-storing frame, wherein the upright posts are steel channels; the supporting discs are arranged on the two side surfaces of the steel channels through pin shafts; the pin shafts divide the supporting discs into two parts with different lengths; supporting disc limit holes corresponding to the supporting discs are formed in the bottom surfaces of the steel channels; when the supporting discs are in a horizontal state, the ends of the longer parts of the supporting discs extend to support materials, and the ends of the shorter parts of the supporting discs are contacted with the upper sides of the supporting disc limit holes; two adjacent upper and lower supporting discs are connected through a supporting disc connecting component; the connecting parts are arranged on the shorter parts of the supporting discs; and load blocks are arranged on the supporting discs connection. Due to the adoption of the technical scheme, the multi-layer material-storing frame is low in manufacturing and using cost and simple and convenient to use; the application range is widened; the limitation to the traditional pneumatic device is avoided; the requirement on automation of a machine is met; and the unloading and loading efficiency of a logistic device is obviously improved.

Owner:芜湖中山科技有限公司

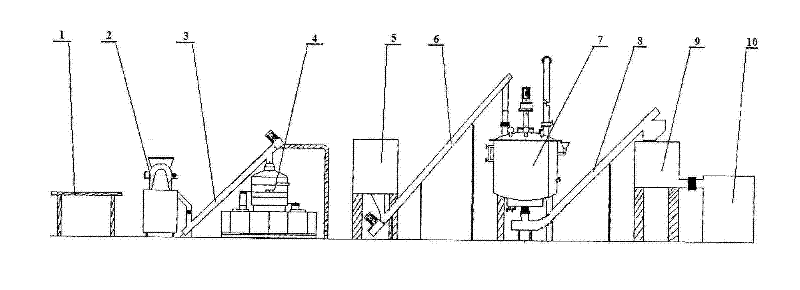

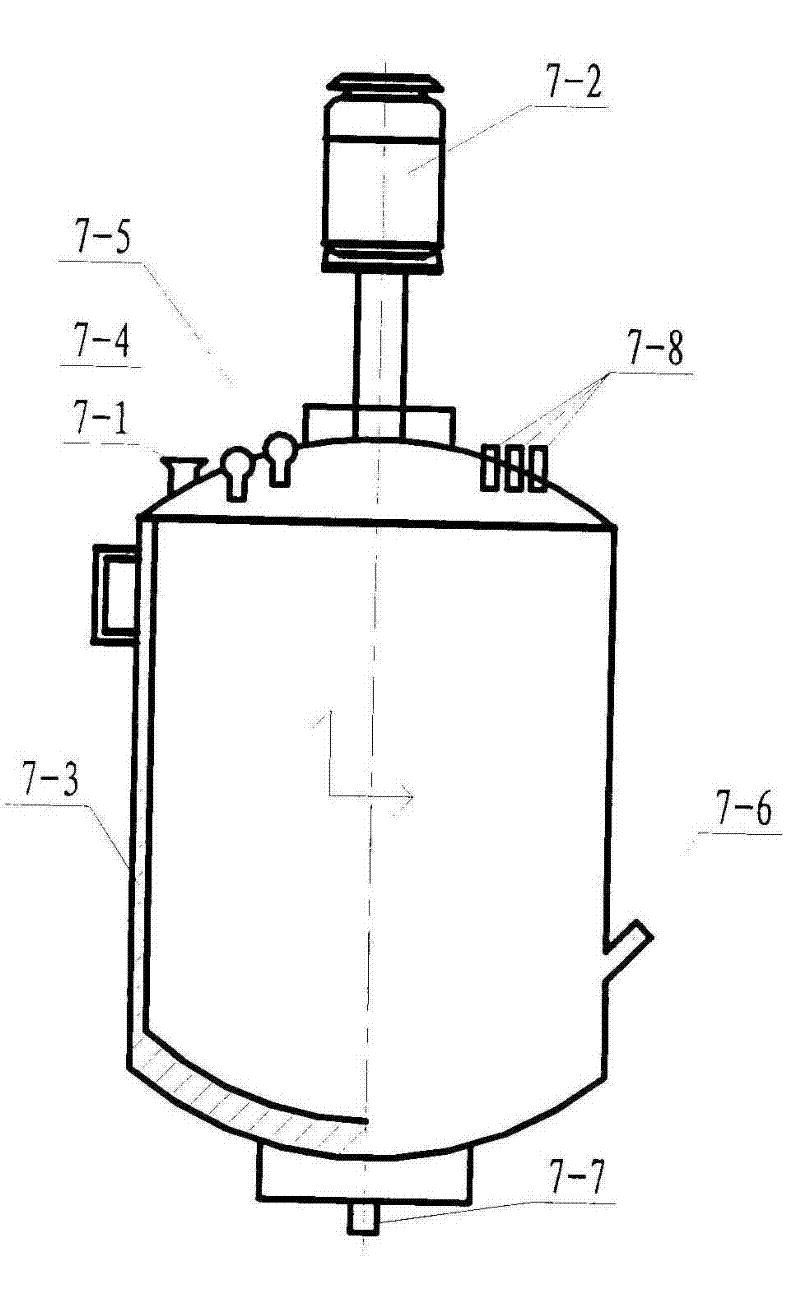

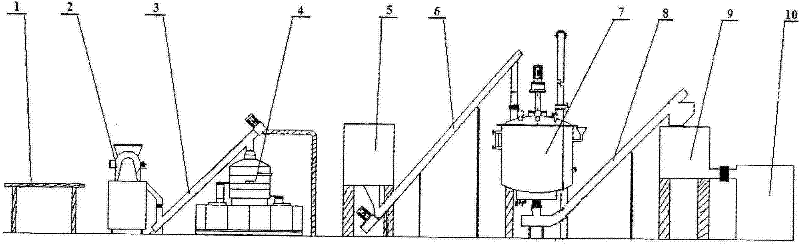

Production line for bagged buccal smokeless tobacco product preparation

ActiveCN102499448AReasonable designOrderly structureTobacco preparationTobacco treatmentProcess engineeringAssembly line

The invention provides a production line for bagged buccal smokeless tobacco product preparation. The production line is characterized by sequentially comprising a tobacco slice loosing table, a crushing device, multi-stage vibration screening equipment, a raw material tobacco powder storage cabinet, tobacco powder treatment equipment, a finished tobacco powder storage cabinet and an automatic package machine, wherein closed conveying belts are connected between the crushing device and the screening equipment, between the raw material tobacco powder storage cabinet and the tobacco powder treatment equipment and between the tobacco powder treatment equipment and the finished product tobacco powder storage cabinet. The production line can realize assembly line work of preparation, treatment, feeding and packaging of tobacco powder, can meet the automatic requirement in laboratory preparation and industrial production process, and the tobacco powder is basically in a closed environment in the processing and conveying process, little dust is generated in the production process; and the production line has the advantages of reasonable design and orderly structure, can be used in assembly line work and product optimization research of a certain step.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

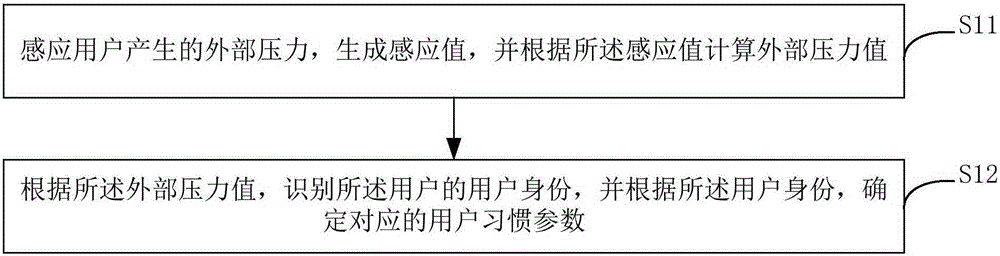

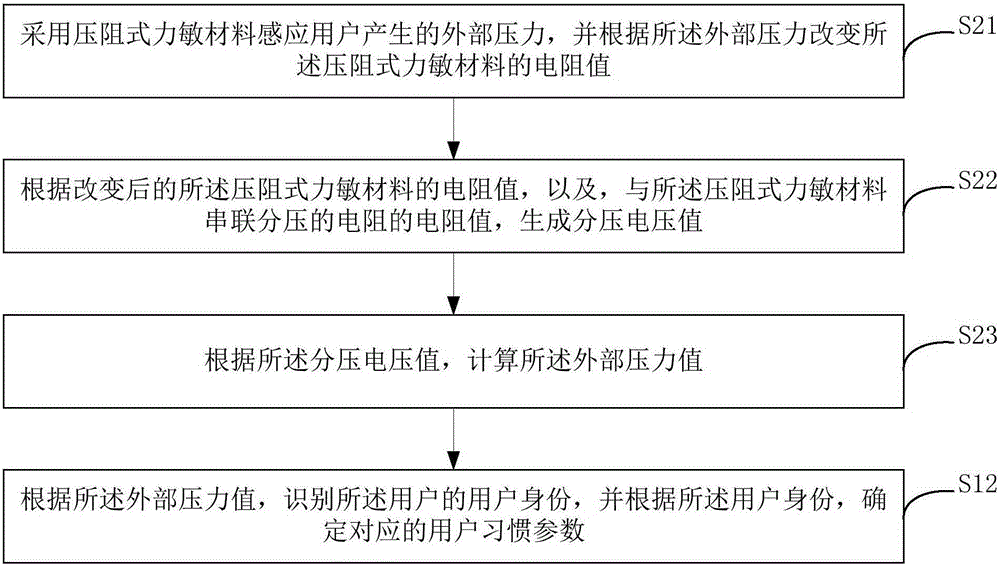

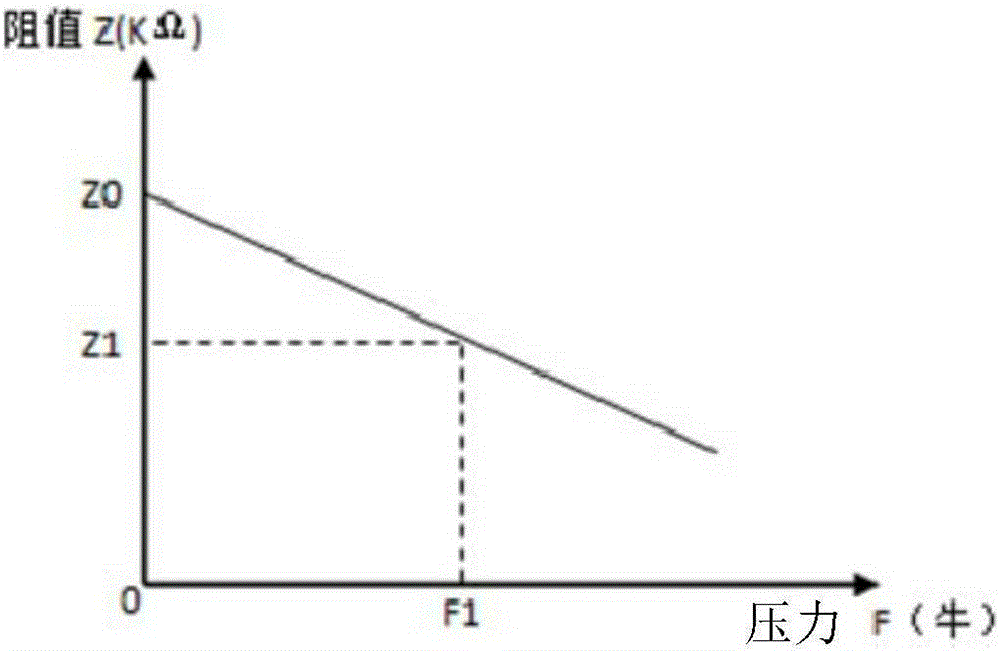

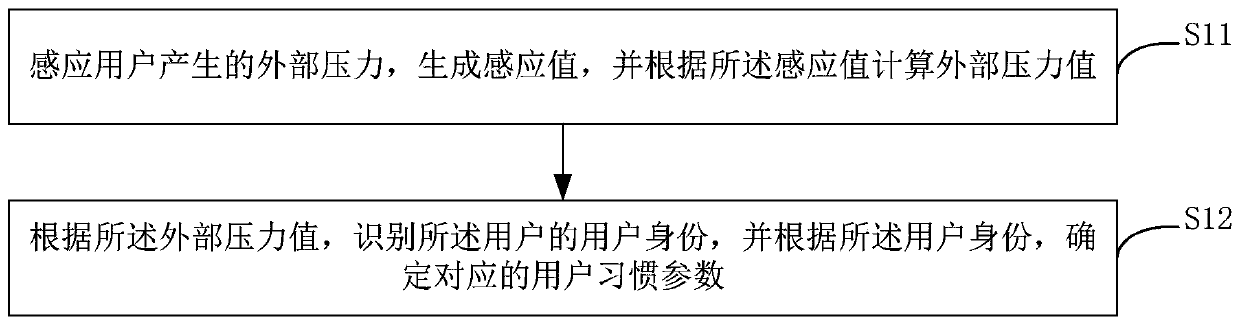

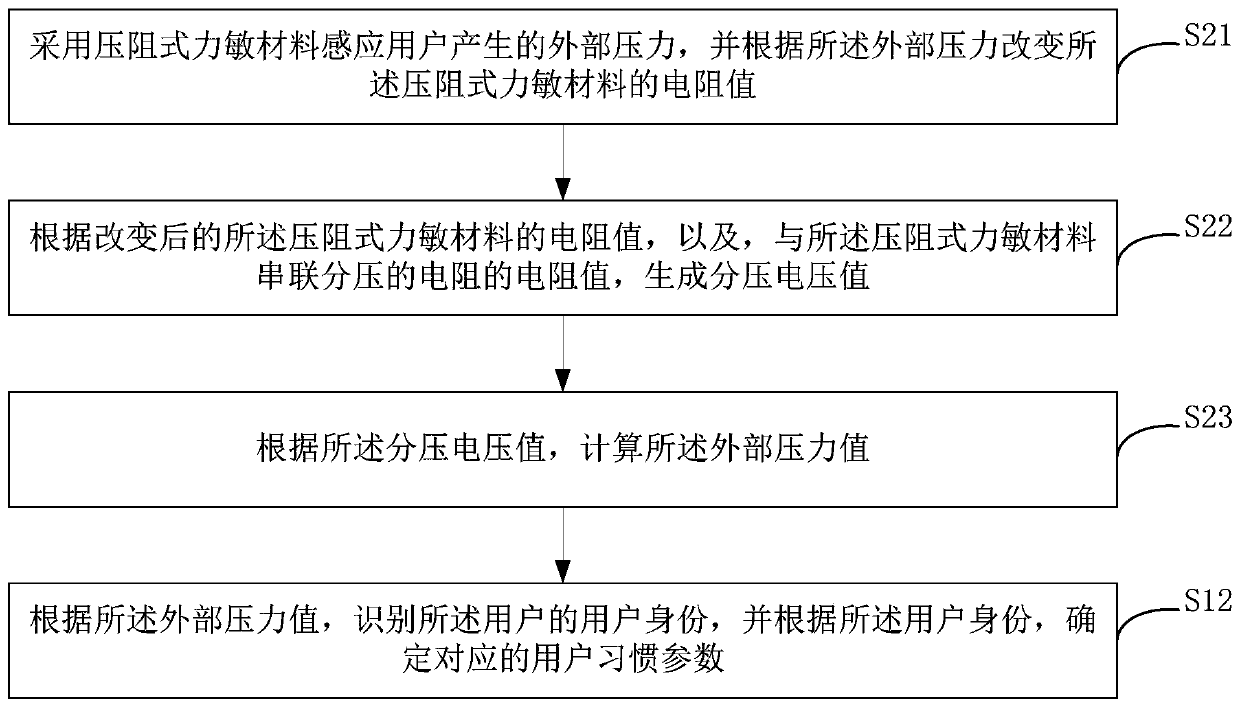

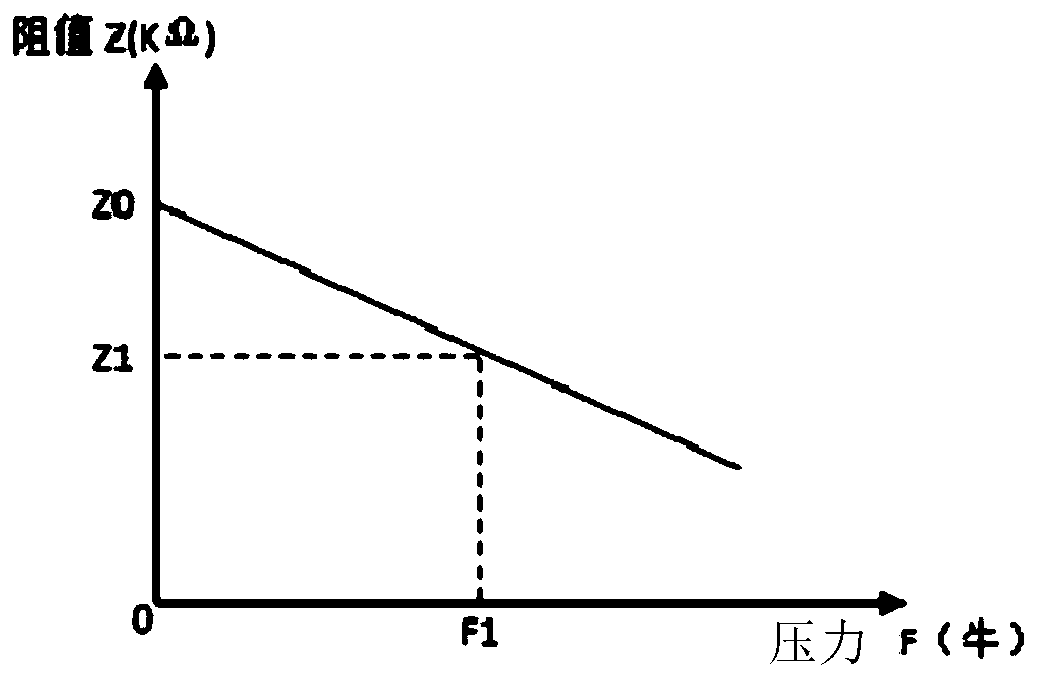

User habit parameter determination method and system

The present invention proposes a user habit parameter determination method and system. The user habit parameter determination method comprises: sensing an external pressure caused by a user, generating a sensing value, and calculating an external pressure value according to the sensing value; and according to the external pressure value, identifying a user identity of the user, and according to the user identity, determining a corresponding user habit parameter. According to the method provided by the present invention, the user identity can be identified, so that the corresponding user habit parameter can be determined, thereby satisfying automation needs.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD +1

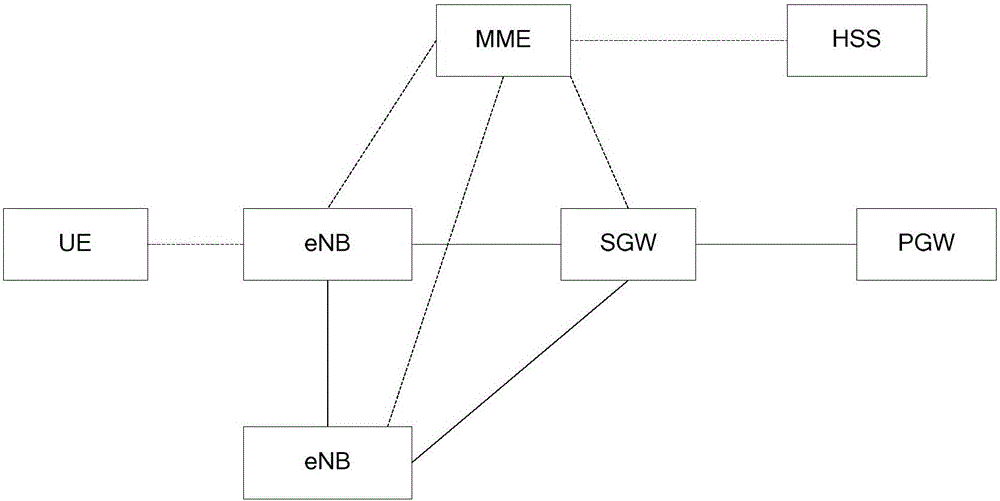

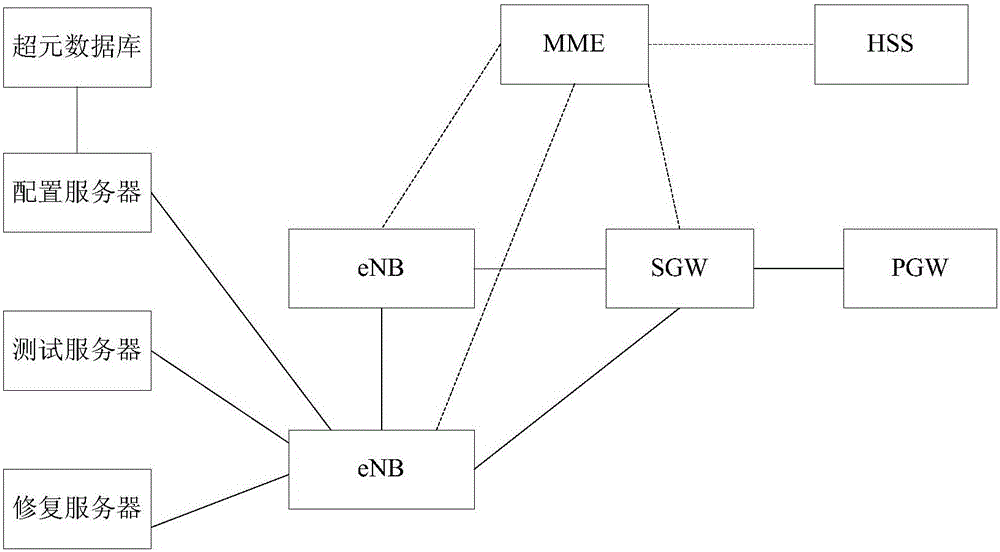

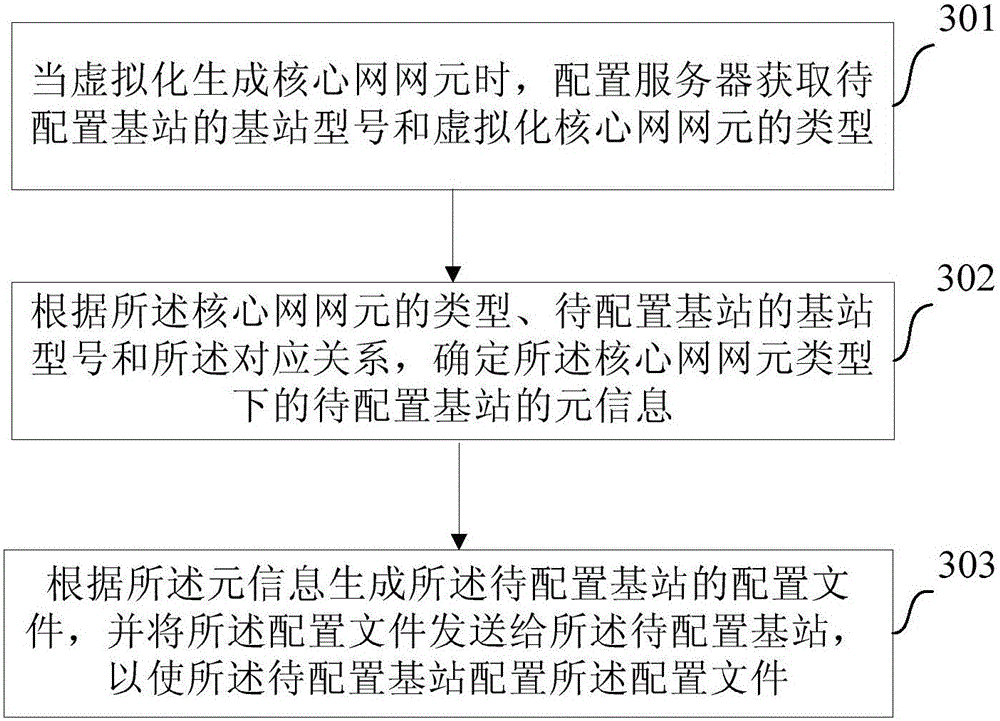

NFV network element configuration method and system

ActiveCN105791018AImplement automatic configurationImprove access capabilitiesData switching networksVirtualizationAuto-configuration

The invention provides a network-function-virtualization (NFV) network element configuration method and system. A corresponding relation between meta information and super meta information of base station types under various core network elements is established; correspondence between meta information and super meta information of various manufactures and base stations with different types is carried out; when a core network element is generated in a virtualized mode, the correspondence relation is queried according to the type of the core network element and a base station type of a to-be-configured base station, so that meta information of the to-be-configured base station is obtained; and thus a configuration file that can be identified by the to-be-configured base station is generated and is sent to the to-be-configured base station, so that automatic configuration of the base station is realized. Therefore, a configuration server can generate a configuration file of a to-be-configured base station with a needed type automatically without hand-operated configuration by the technical staff of the corresponding manufacturer, so that the labor cost is saved, the access capability of the base station equipment is improved, and the automatic demand of elastic capability expansion of the NFV system is satisfied.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

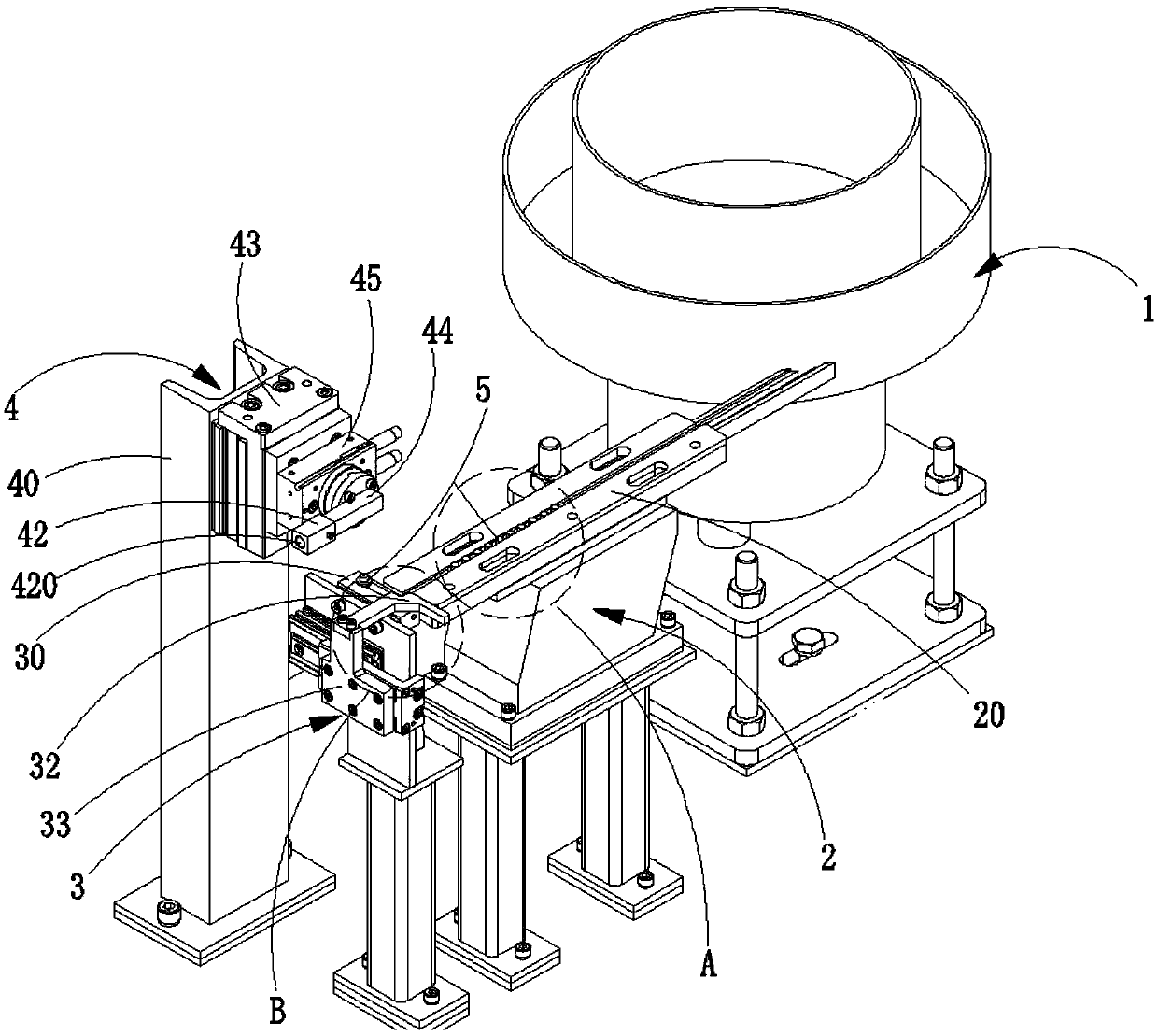

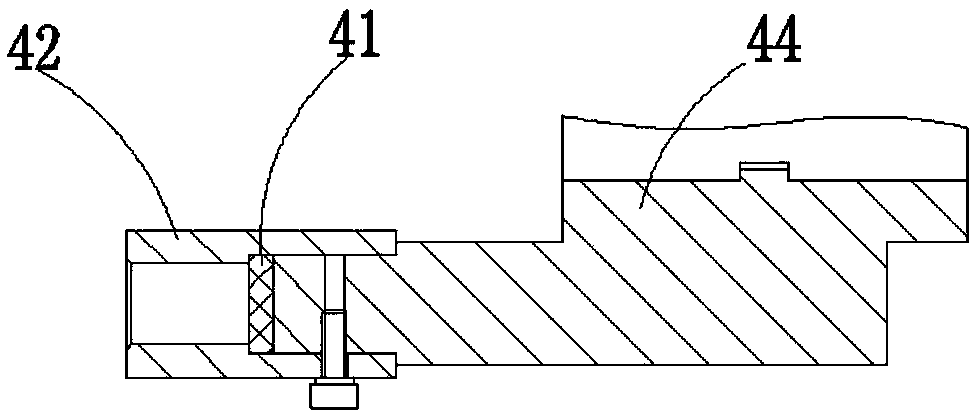

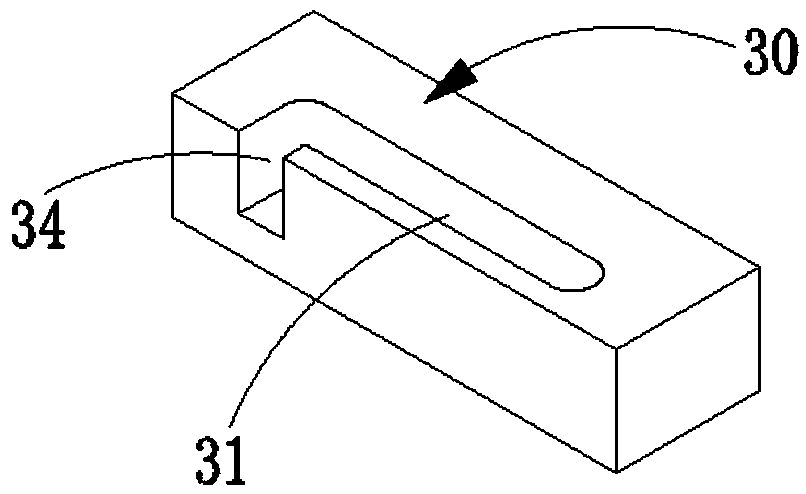

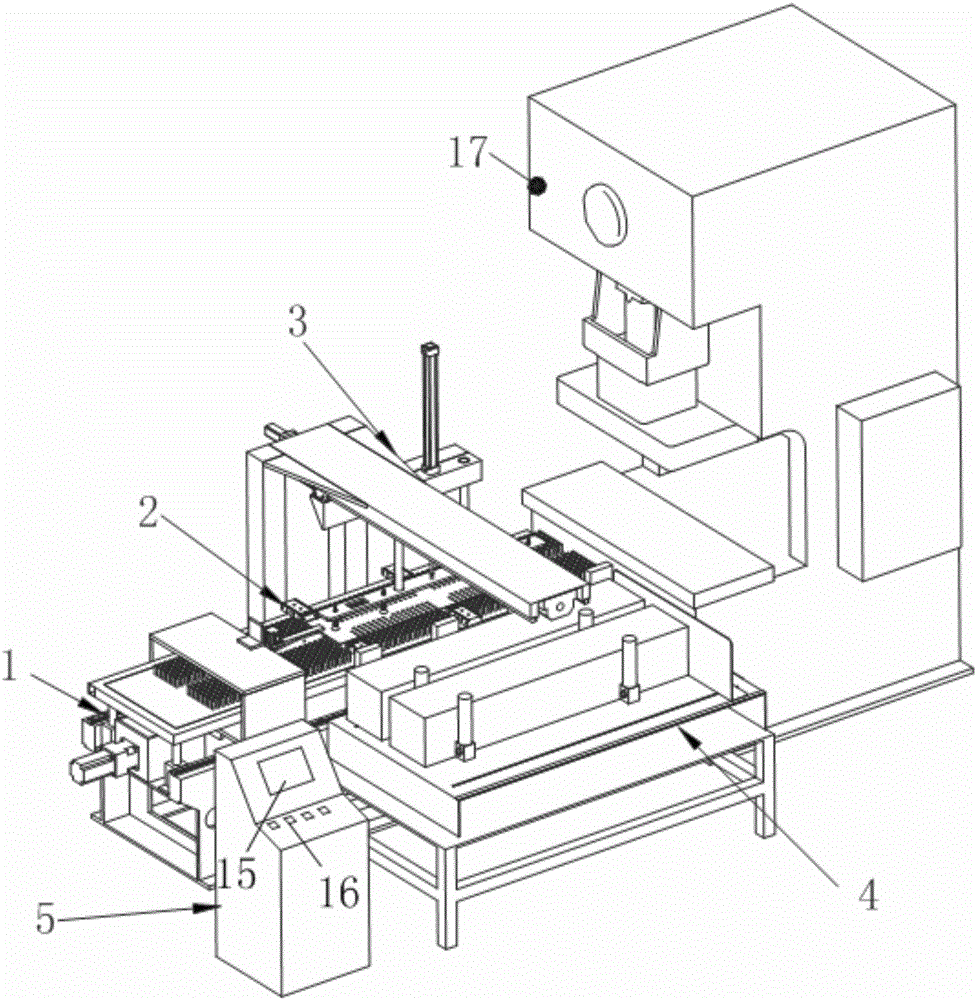

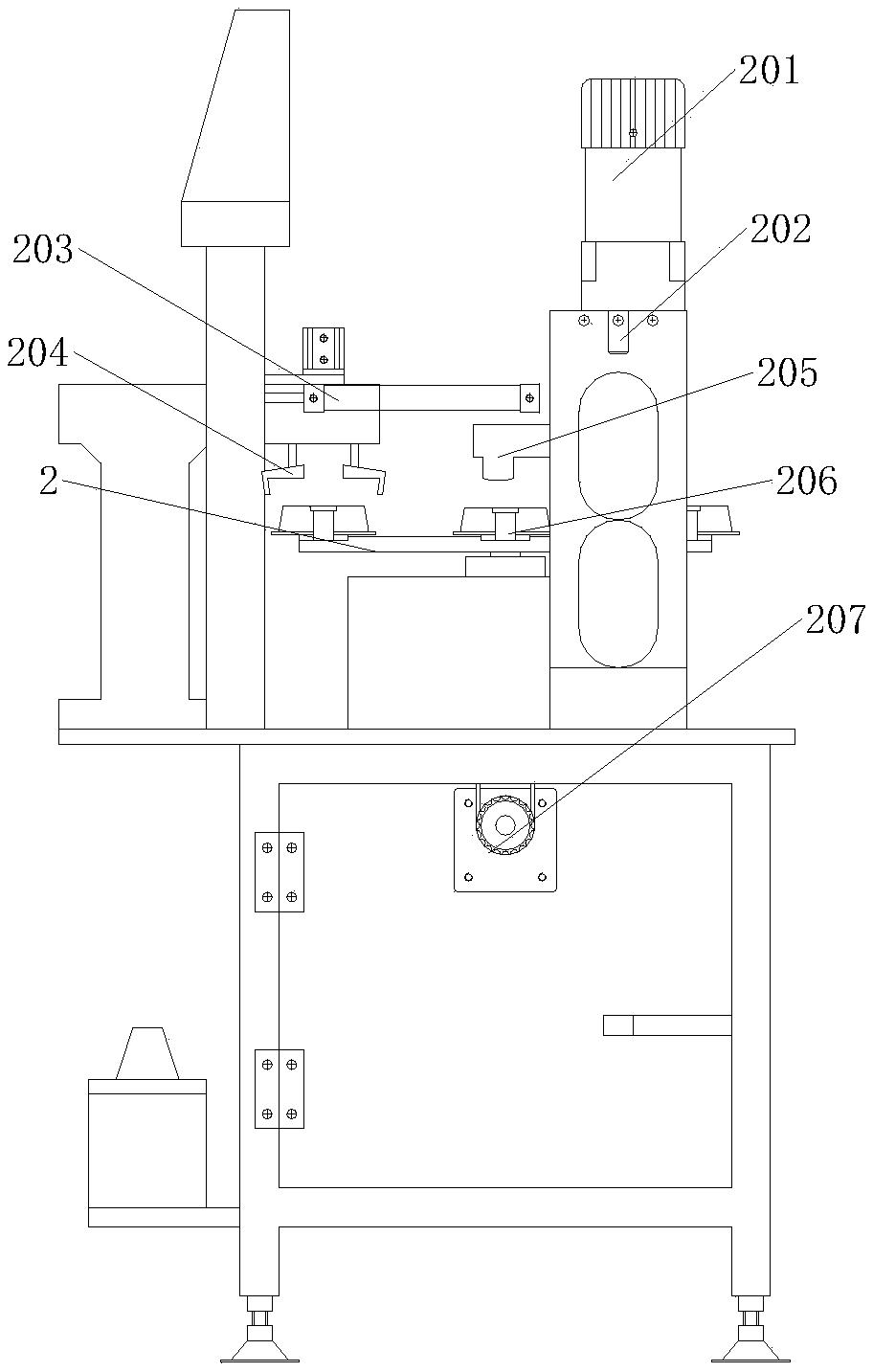

Welding nail feeding system

PendingCN109623251ARealize automatic feedingMeeting Automation NeedsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to the technical field of welding nail feeding, and provides a welding nail feeding system. The welding nail feeding system comprises a feeding end and a discharging end, and further comprises a vibrating disc, a feeding mechanism, a material distributing mechanism and a material taking mechanism, wherein the vibrating disk is used for arranging scattered welding nails, the feeding mechanism is used for conveying the arranged welded nails, the material distributing mechanism is used for outputting the welding nails conveyed by the feeding mechanism one by one, and the material taking mechanism is used for taking away the welding nails in the material distributing mechanism, wherein the vibrating disc, the feeding mechanism, the material distributing mechanism and thematerial taking mechanism are sequentially arranged in the direction from the feeding end to the discharging end. According to the welding nail feeding system, the vibrating disc, the feeding mechanism, the material distributing mechanism and the material taking mechanism are matched with each other, so that automatic feeding of the welding nails is realized, the automatic requirements of the label welding process can be met.

Owner:WISDRI ENG & RES INC LTD

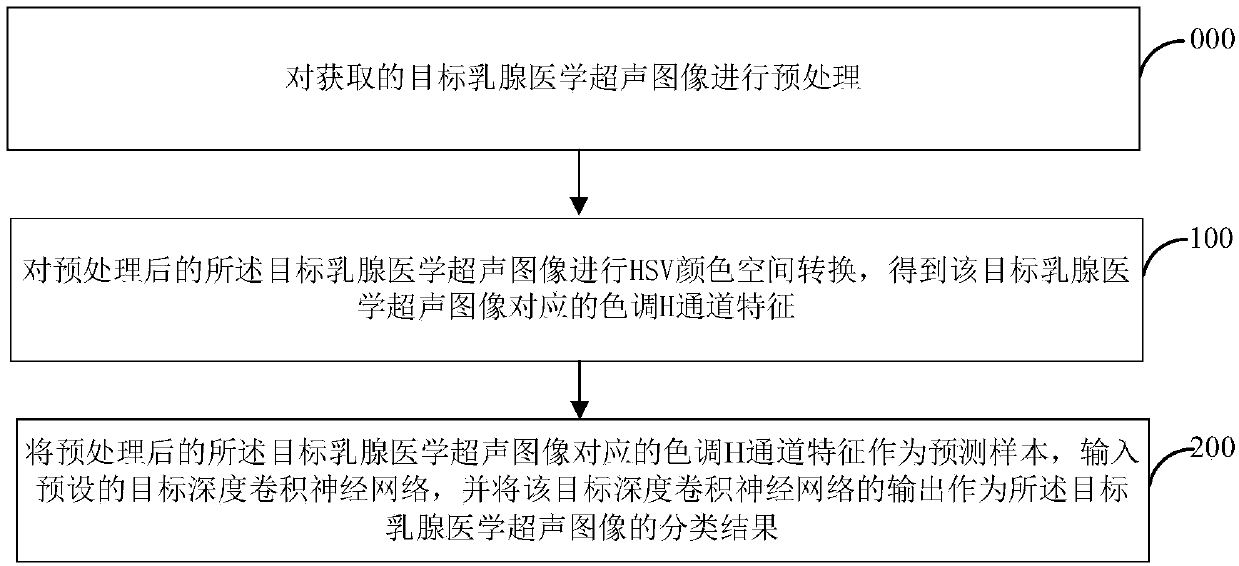

Automatic classification method and device for mammary gland medical ultrasonic images

InactiveCN109614993AImprove accuracyImprove efficiencyRecognition of medical/anatomical patternsRadiologyClassification methods

The invention provides an automatic classification method and device for mammary gland medical ultrasonic images. The method comprises the steps of preprocessing an obtained target mammary gland medical ultrasonic image; performing HSV color space conversion on the preprocessed target breast medical ultrasonic image to obtain a hue H channel feature corresponding to the target breast medical ultrasonic image; and taking the hue H channel feature corresponding to the preprocessed target breast medical ultrasonic image as a prediction sample, inputting the prediction sample into a preset targetdeep convolutional neural network, and taking the output of the target deep convolutional neural network as a classification result of the target breast medical ultrasonic image. The breast medical ultrasonic image classification method and device can effectively improve the accuracy and efficiency of feature recognition of the breast medical ultrasonic image, can effectively and reliably improvethe high efficiency and intelligent degree of the classification process of the breast medical ultrasonic image, and can improve the accuracy of the classification result of the breast medical ultrasonic image.

Owner:SHENZHEN INST OF ADVANCED TECH

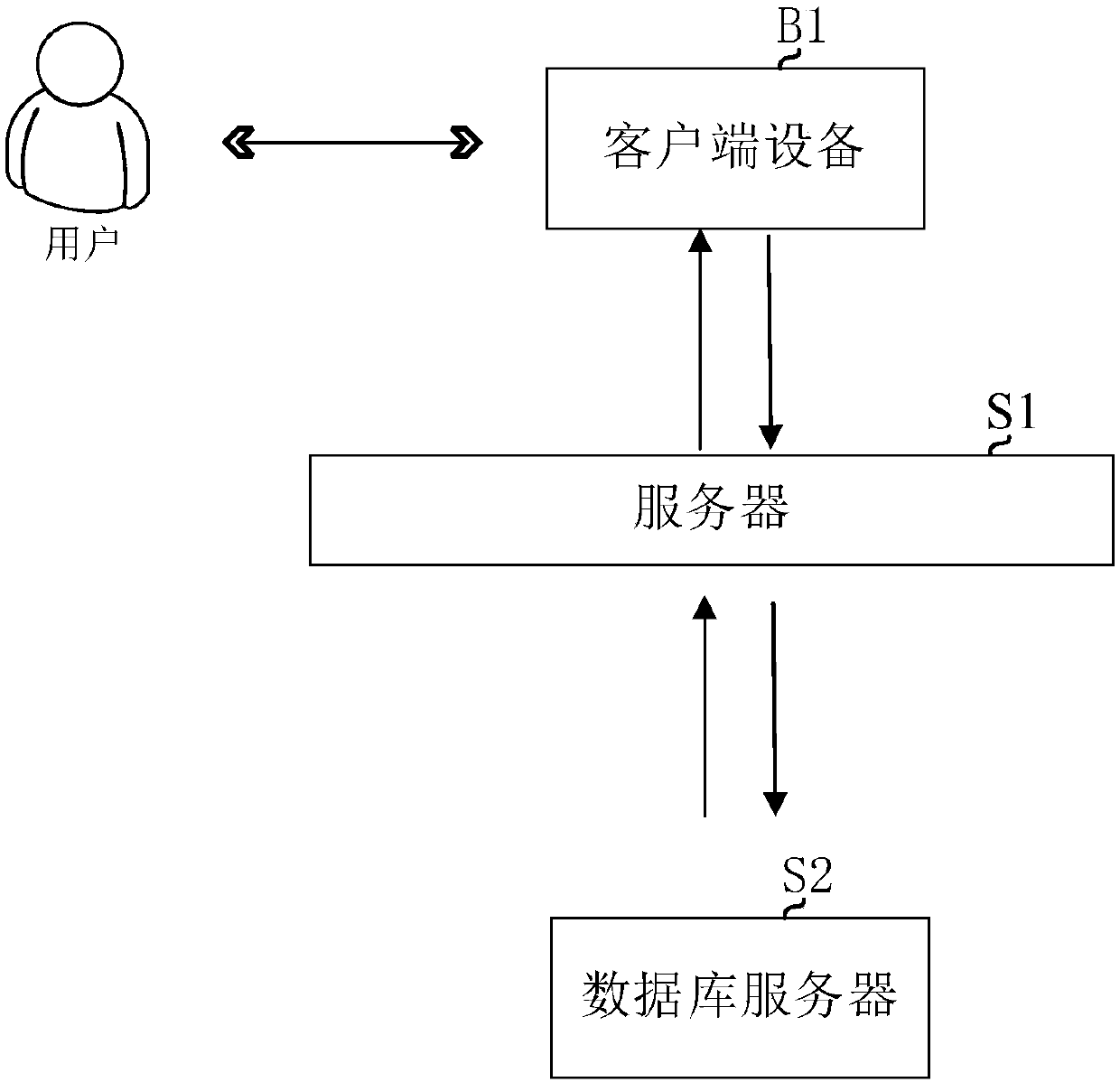

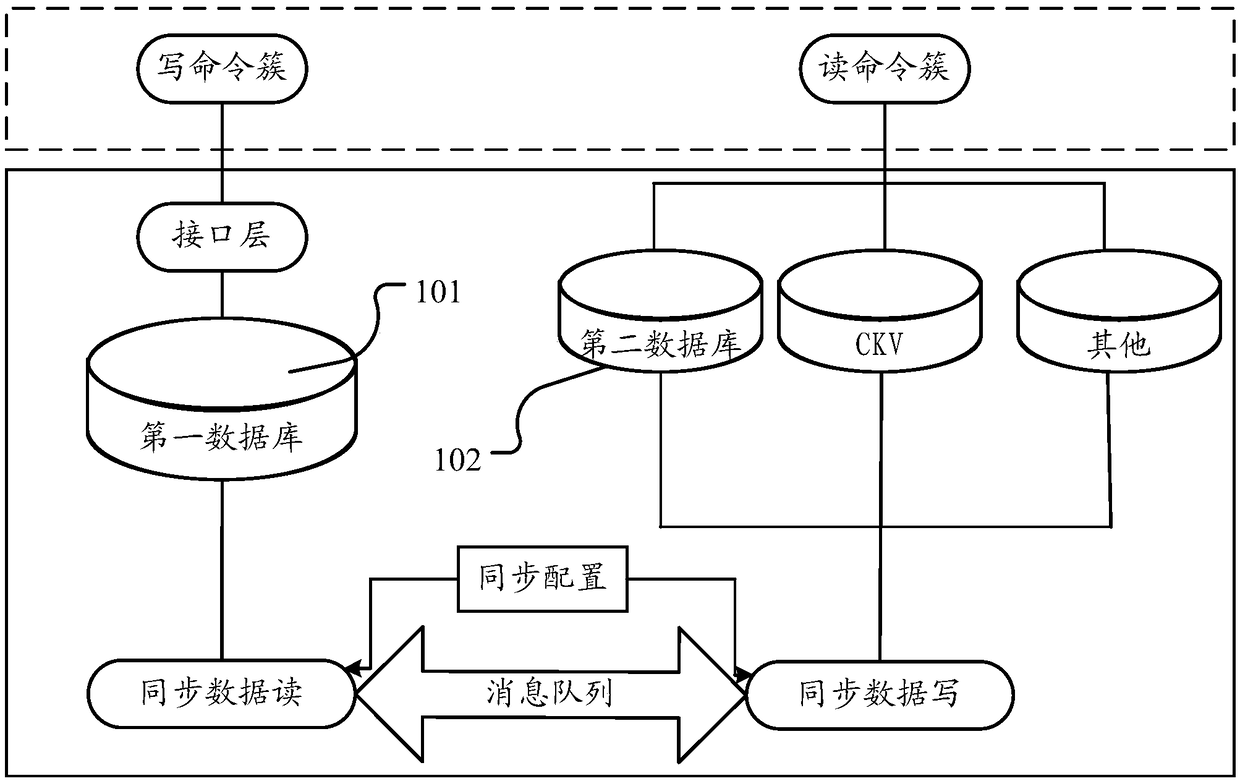

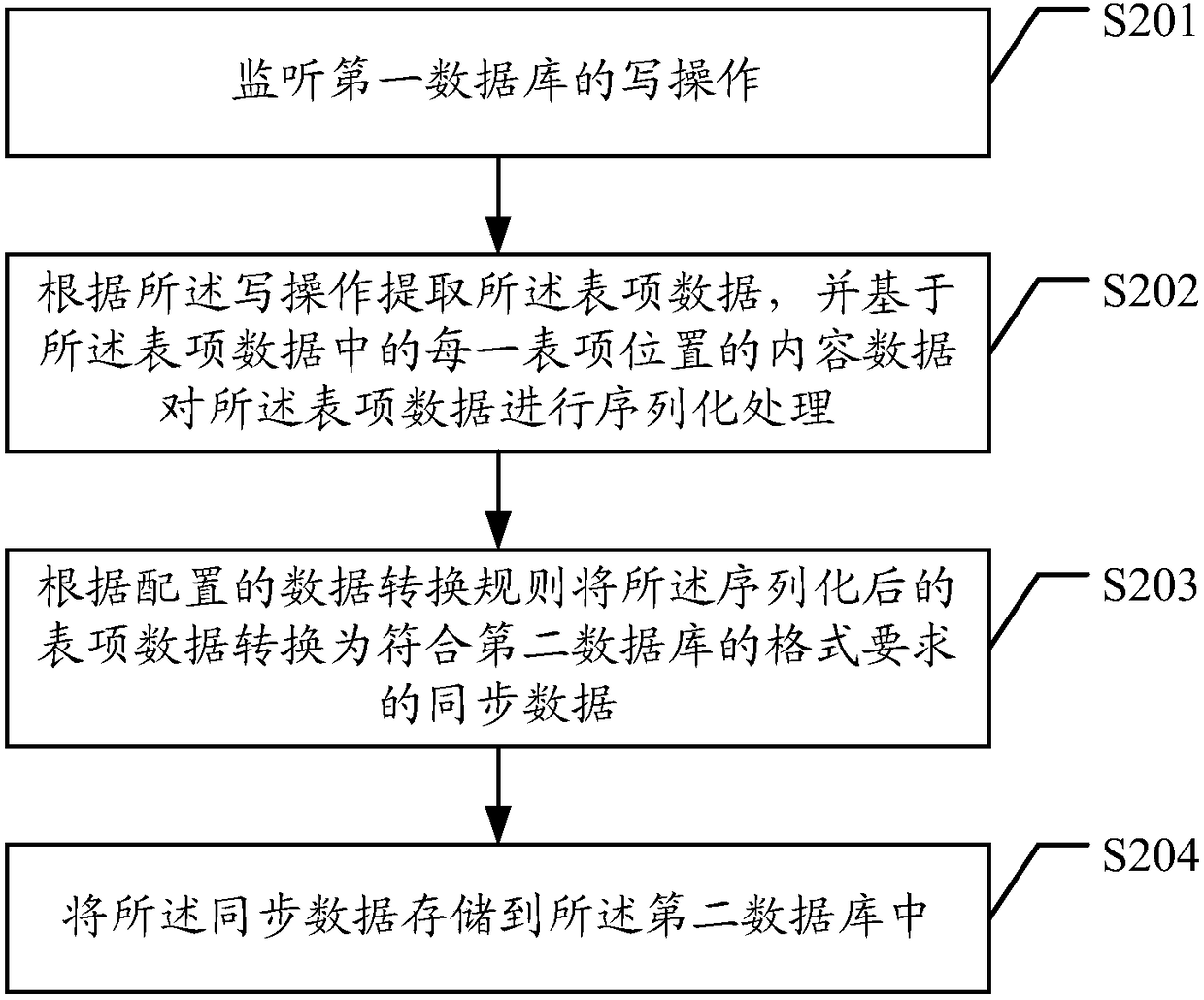

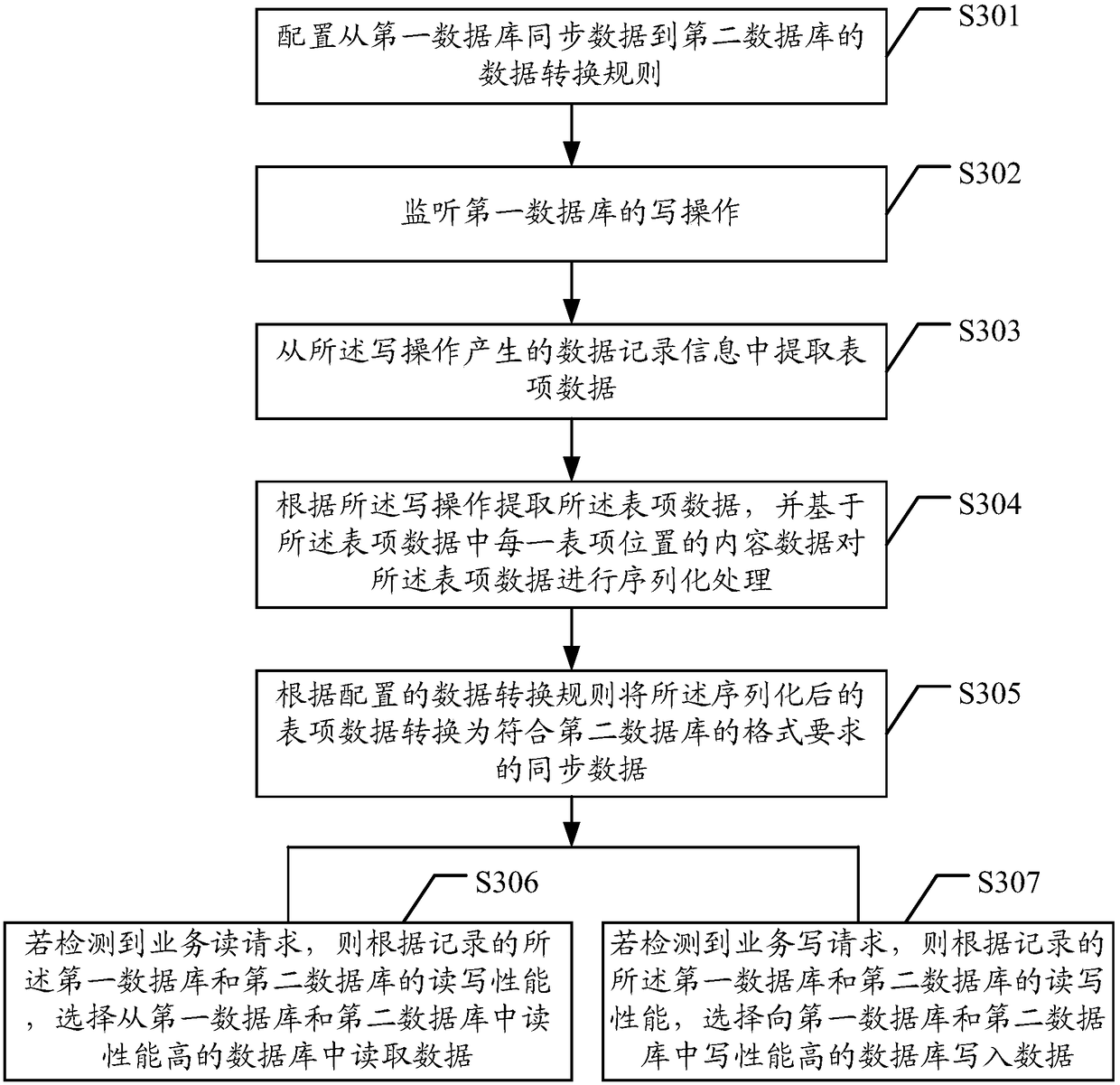

Data synchronization method and device and storage device

ActiveCN108628885AImprove synchronization efficiencyMeet the needs of automationEnergy efficient computingSpecial data processing applicationsData synchronizationSerialization

The embodiment of the invention discloses a data synchronization method and device and a storage device. The method comprises the steps that writing operation on a first database is monitored, whereinthe writing operation comprises the operation of writing new table item data into the first database; the table item data is extracted according to the writing operation, and serialization processingis performed on the table item data based on content data at each table item position in the table item data; the table item data obtained after serialization is converted into synchronous data meeting the format requirement of a second database according to configured data conversion rules; and the synchronous data is stored into the second database. By the adoption of the embodiment, synchronization of the data between different types of databases can be automatically completed, the automation demand of a user for data synchronization is met, and the efficiency of performing data synchronization between different types of databases is improved.

Owner:TENCENT CLOUD COMPUTING BEIJING CO LTD

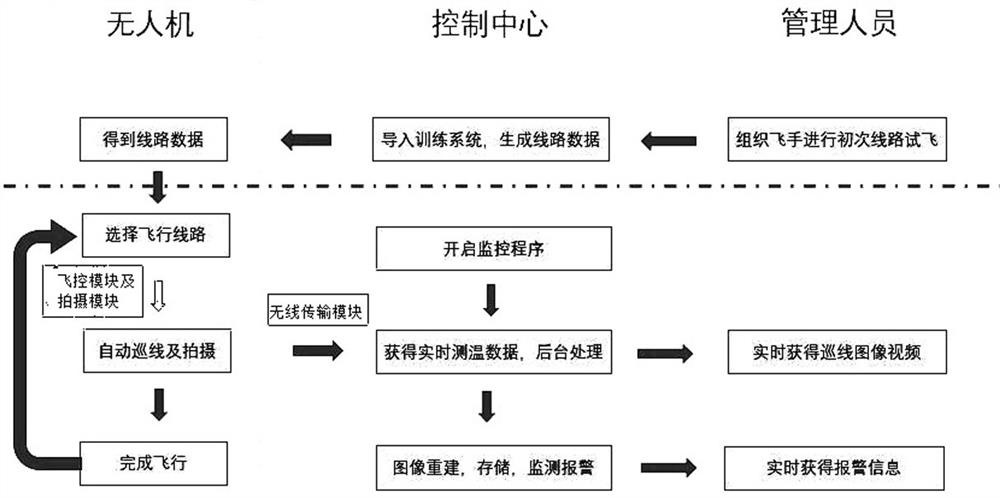

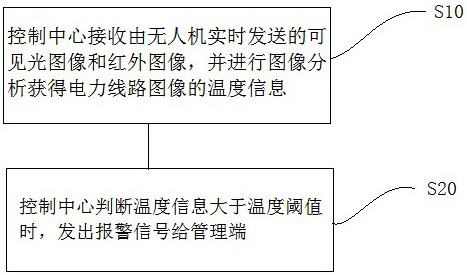

Power line automatic temperature measurement method based on unmanned aerial vehicle line patrol

PendingCN112067137ASolve efficiency problemsResolve accuracyRadiation pyrometryClosed circuit television systemsImaging analysisUncrewed vehicle

The invention discloses a power line automatic temperature measurement method based on unmanned aerial vehicle line patrol, and relates to the technical field of power system line patrol. The method is realized through a power line automatic temperature measurement system based on unmanned aerial vehicle line patrol. The system comprises an unmanned aerial vehicle, a control center and a management terminal. A camera device for shooting a visible light image and an infrared image is mounted on the unmanned aerial vehicle; the method comprises the steps that S10, a control center receives a visible light image and an infrared image which are sent by an unmanned aerial vehicle in real time and carries out image analysis to obtain temperature information of an electric power circuit image; and S20, when the control center judges that the temperature information is larger than the temperature threshold value, an alarm signal is sent to the management end. The device is used for fault inspection of unmanned aerial vehicle line patrol, image real-time acquisition is carried out on a power line through unmanned aerial vehicle full-automatic line patrol, a control center carries out analysis processing and monitoring alarm on an image, and the automation requirement is met.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO

Tubing coupling detection device and reducing pipe column detection device

ActiveCN113738348AAvoid triggerMeet the needs of automationSurveyGeothermal energy generationRadial planeWorkover

The invention provides a tubing coupling detection device and a reducing pipe column detection device. The tubing coupling detection device comprises a static platform, a movable platform and a detector, wherein the static platform can be fixed to a wellhead and is provided with a first through hole for a pipe column moving axially to penetrate through; the movable platform is movably arranged on the static platform, is provided with a second through hole for the pipe column to penetrate through and can move relative to the static platform along a first plane parallel to the radial plane of the pipe column; and the detector is movably mounted on the movable platform and makes contact with the outer wall of the pipe column, the detector and the movable platform can move along the first plane along with the pipe column and keep relatively static when the pipe column deviates radially, and a tubing coupling of the pipe column enables the detector to move relative to the movable platform and trigger the detector when passing through the detector. The tubing coupling detection device is high in detection accuracy and can meet the requirement for automation of operation under pressure and workover treatment.

Owner:PETROCHINA CO LTD

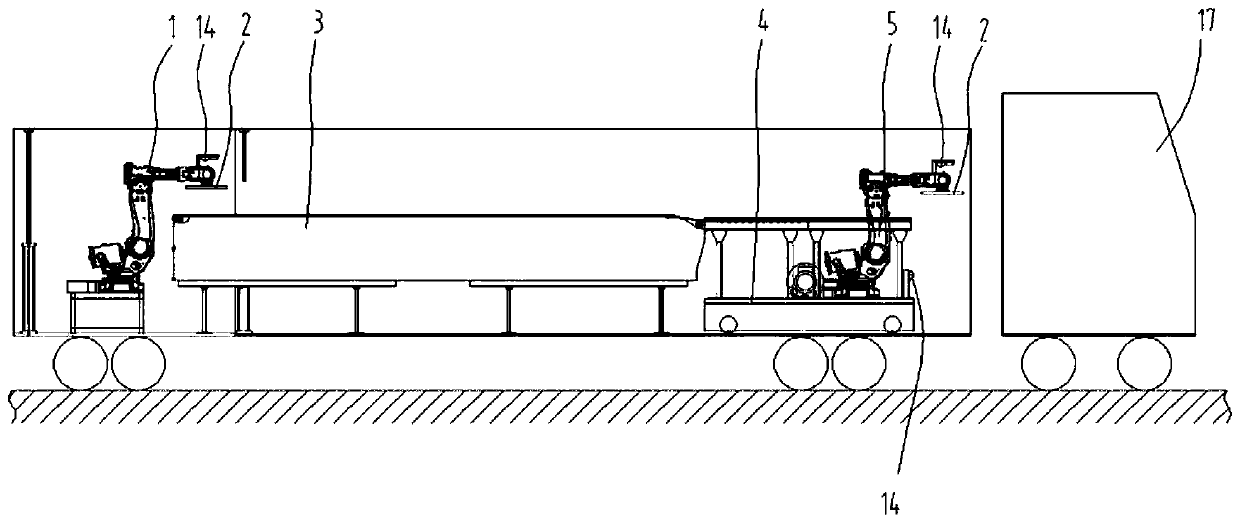

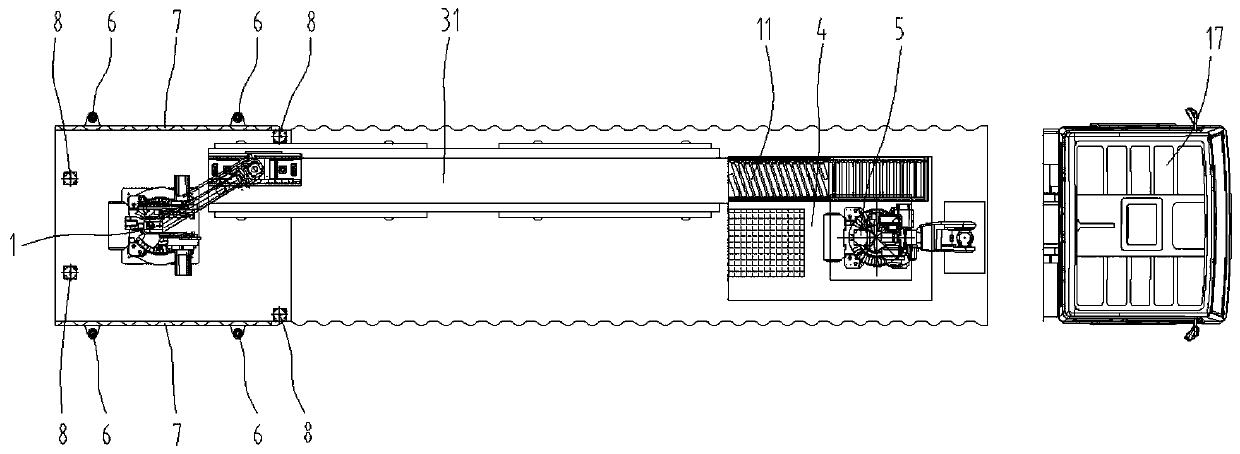

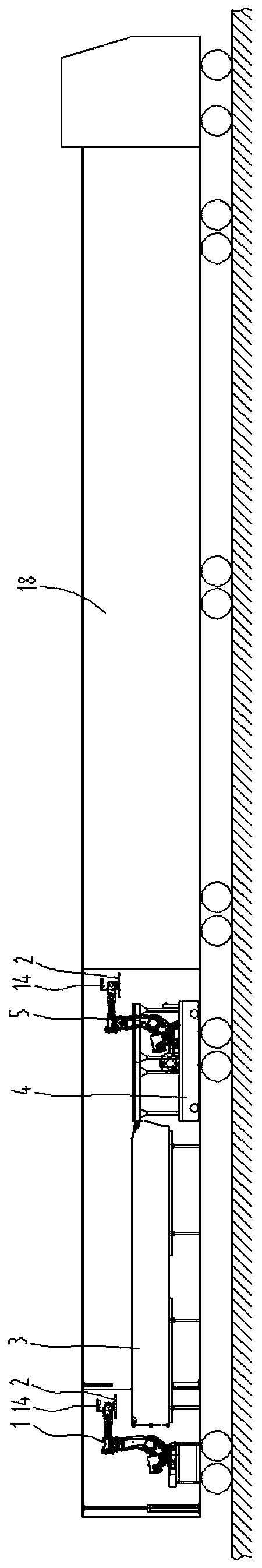

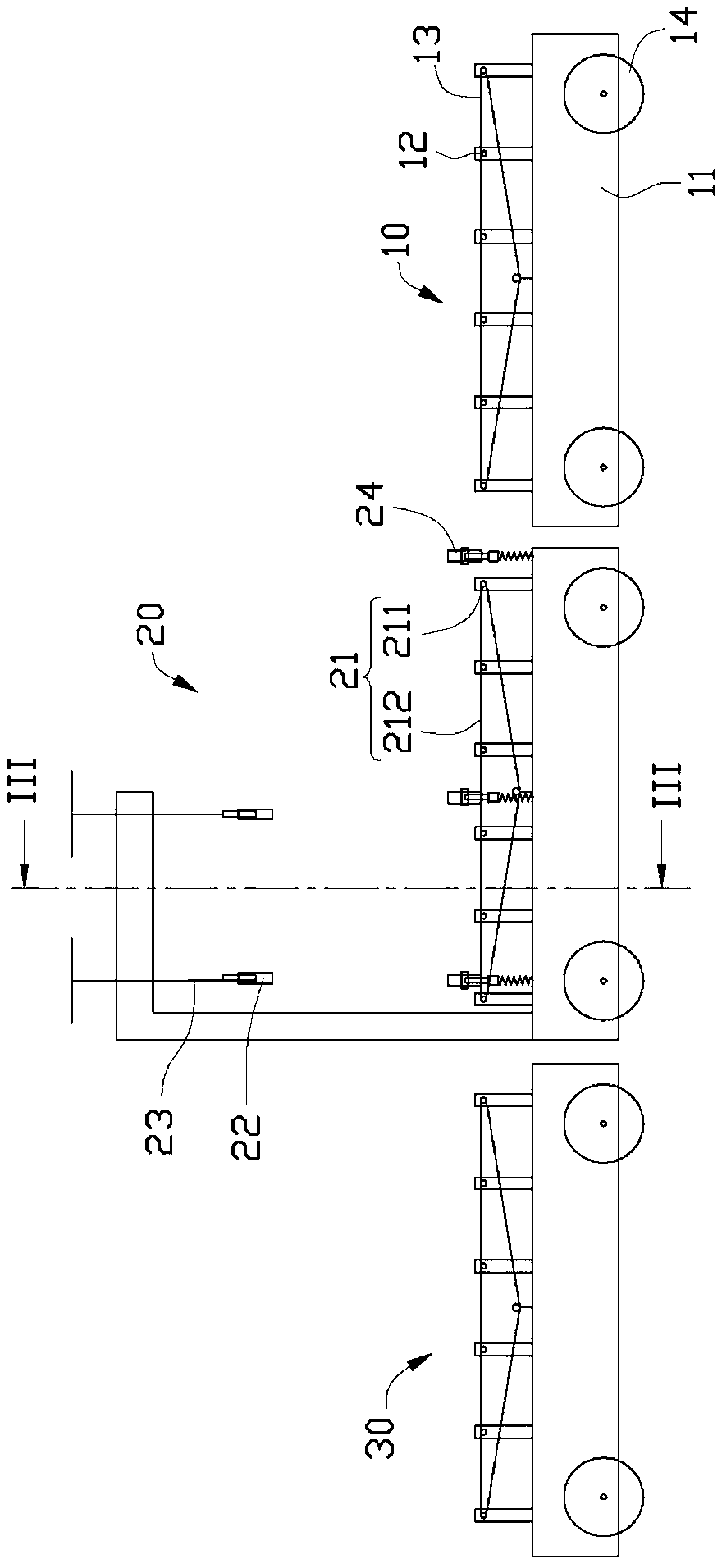

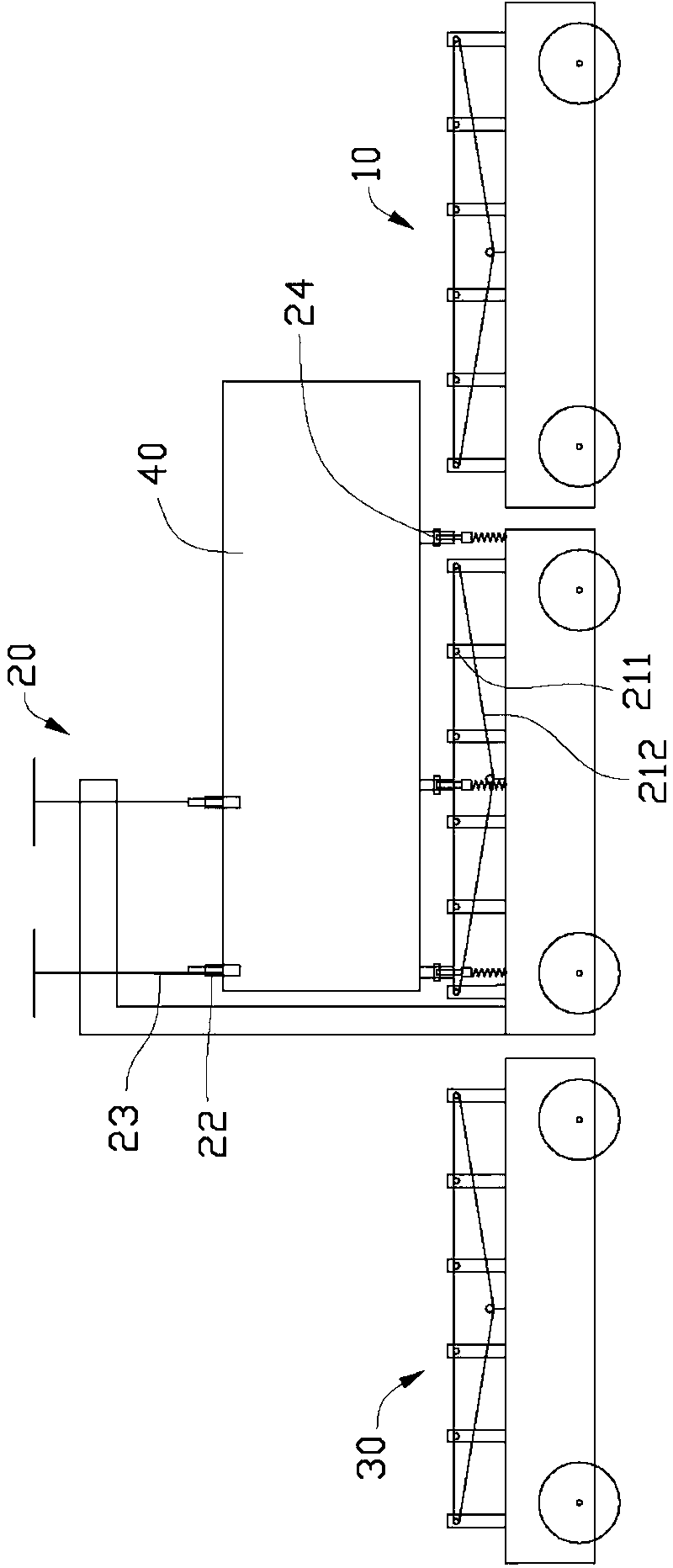

Container loading and unloading vehicle platform, container loading and unloading vehicle system and loading and unloading method

PendingCN109795394AStable structureFlexible moving processVehicle with endless chains/beltsEngineeringConveyor belt

The invention discloses a container loading and unloading vehicle platform, a container loading and unloading vehicle system and a loading and unloading method, and belongs to the technical field of container loading and unloading. The container loading and unloading vehicle platform comprises a carriage, a stretchable conveying mechanism, a material taking and placing mechanism and a movable loading and unloading mechanism, wherein the stretchable conveying mechanism is arranged in the middle of the carriage and comprises a conveying belt and a stretchable mechanism, the conveying belt is arranged on the stretchable mechanism, and the stretchable mechanism can drive the conveying end of the conveying belt to move along the length direction of the carriage; the material taking and placingmechanism is arranged at the fixed end of the stretchable conveying mechanism and can place materials to be loaded on the conveying belt and take down materials to be unloaded on the conveying belt; and the movable loading and unloading mechanism is connected with the conveying end of the conveying belt, can move along the length direction of the carriage, and can take down materials from the conveying belt and place the materials in a container truck or take the materials out of the container truck and place the materials on the conveying belt. After the dock of the container vehicle platformand the container truck are completed, the conveyor belt and the movable loading and unloading mechanism can move into the container truck, and then automatically carry out corresponding material loading and unloading operations.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

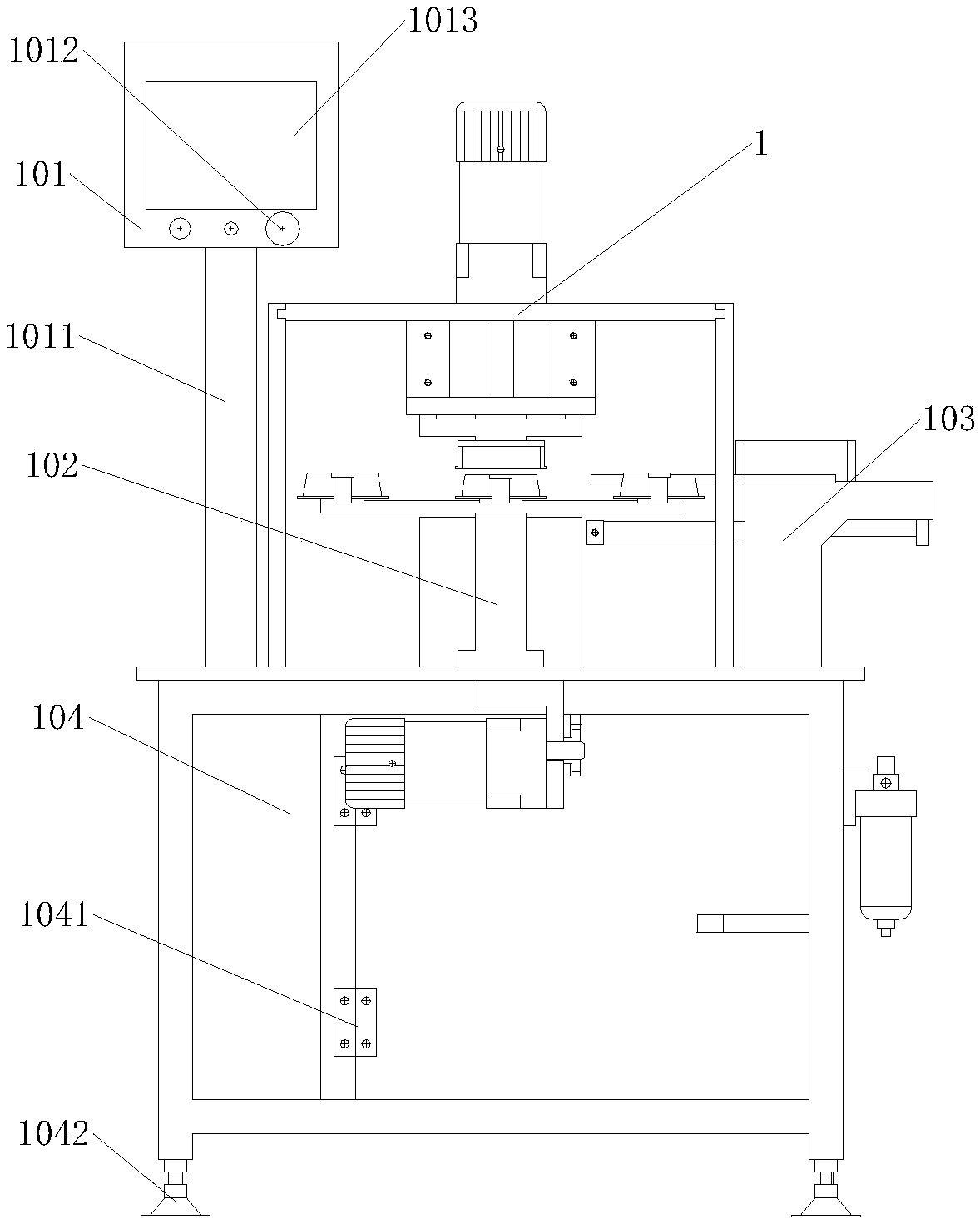

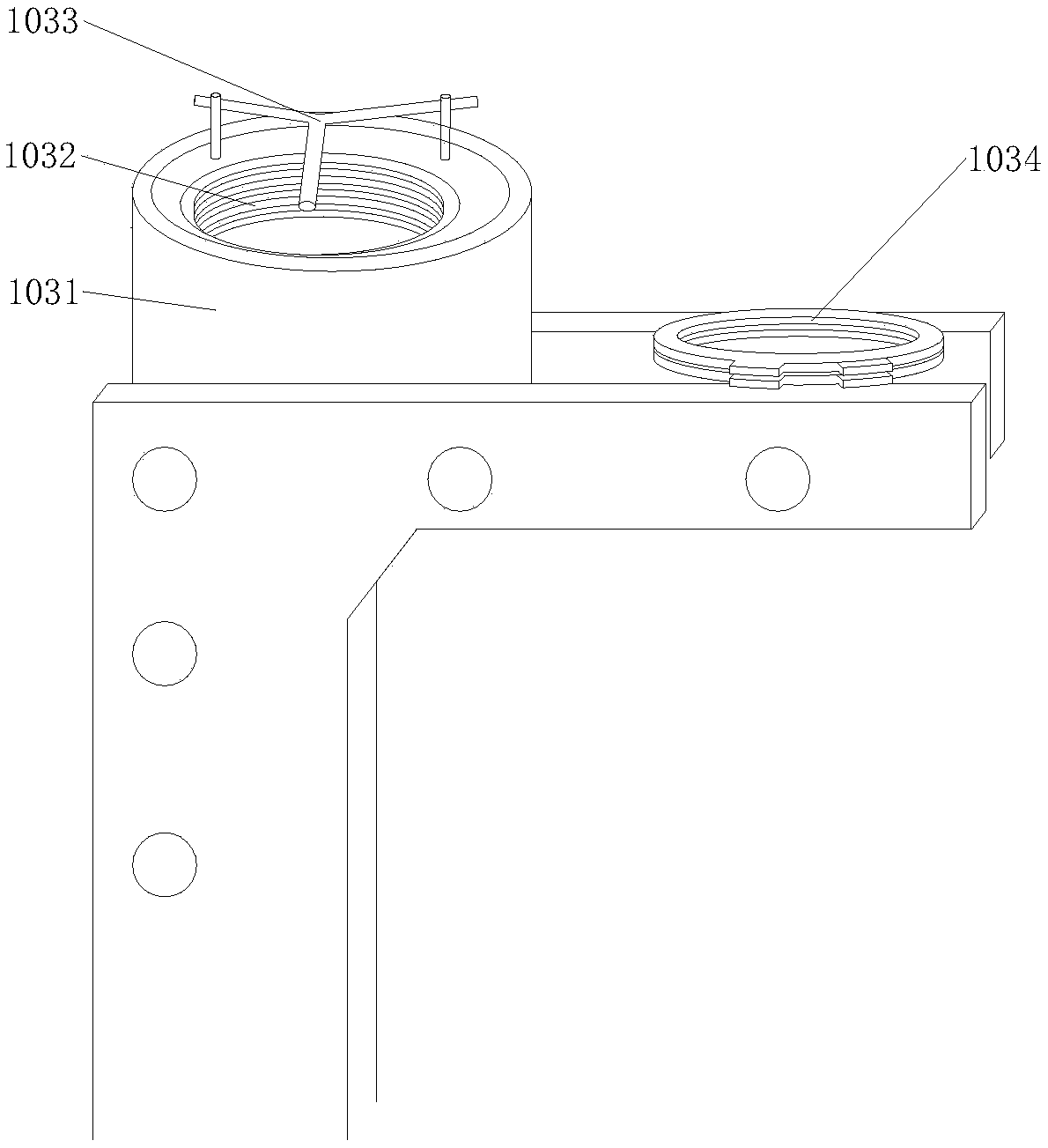

Automatic pipe cutting device

InactiveCN103213156AMeeting Automation NeedsMeet the needs of automationMetal working apparatusProduction lineEngineering

The invention provides an automatic pipe cutting device which is used for cutting a tubular product. The automatic pipe cutting device comprises a material feeding mechanism, a material cutting mechanism and a material discharging mechanism, wherein the material feeding mechanism is used for conveying the tubular product; the material cutting mechanism is arranged in a downstream direction of the material feeding mechanism and is used for adjusting the position of the tubular product and cutting the tubular product; the material cutting mechanism comprises a pipe conveying device, supporting devices arranged at the two sides of the pipe conveying device, and a pipe pressing device and a pipe cutter arranged above the pipe conveying device, wherein the supporting devices, the pipe pressing device and the pipe cutter can move relative to the pipe conveying device; and the material discharging mechanism is arranged in the downstream direction of the material cutting mechanism and is used for conveying the tubular product cut by the material cutting mechanism. The automatic pipe cutting device disclosed by the invention can realize operation with higher automation from processes of feeding, fixing and cutting to the process of discharging, so that the automatic pipe cutting device can be matched with an automatic production line and the automation requirements of a modern manufacturing industry can be met.

Owner:GOLD HONG YE PAPER

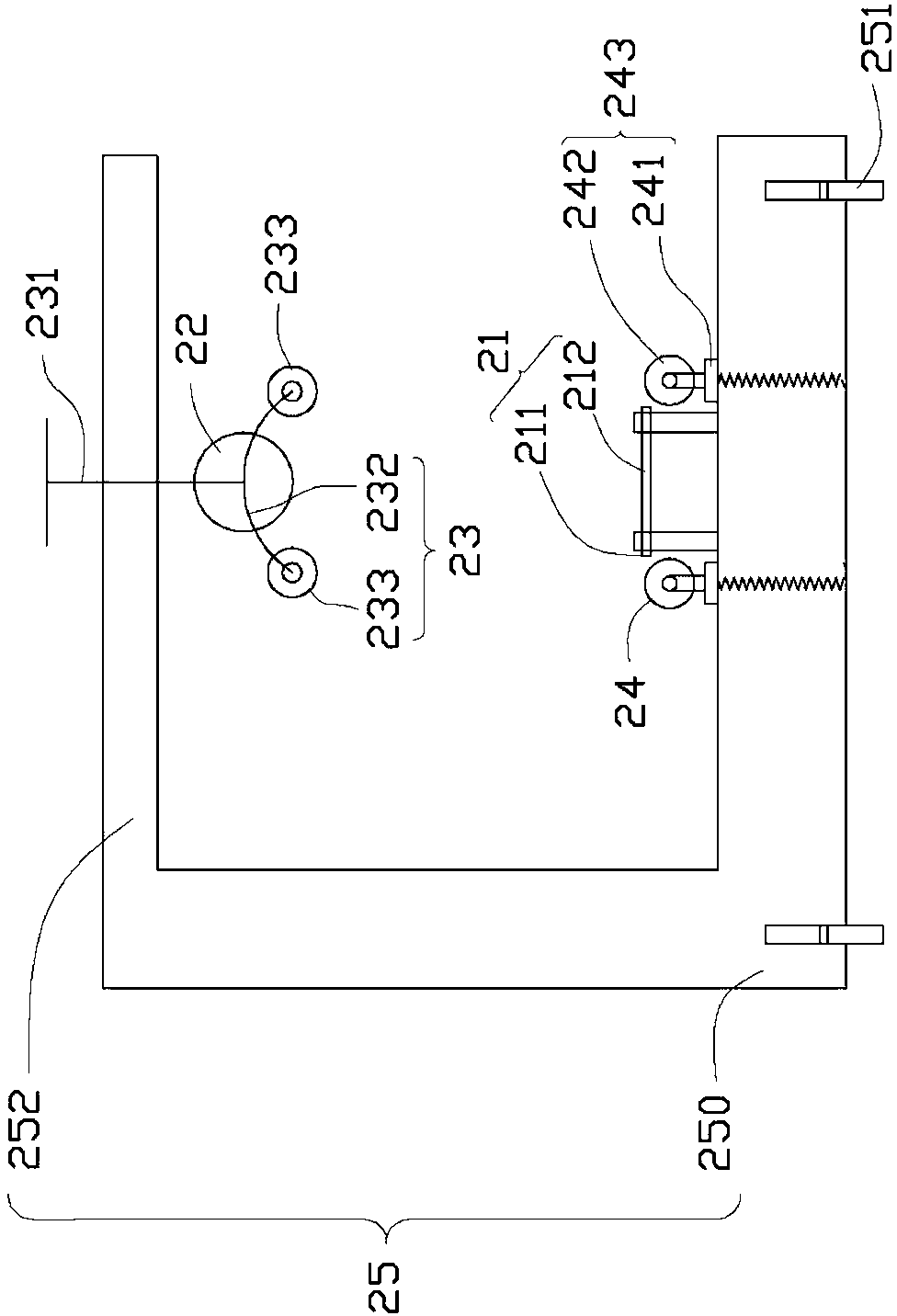

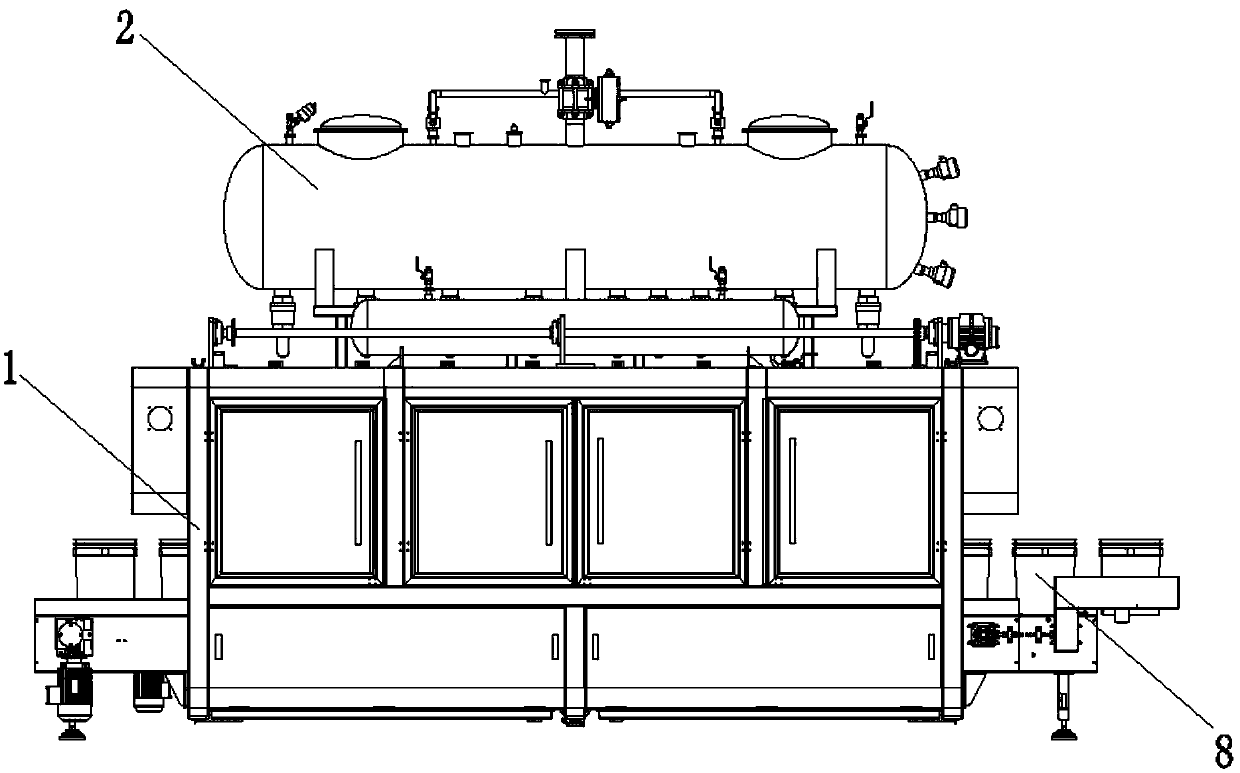

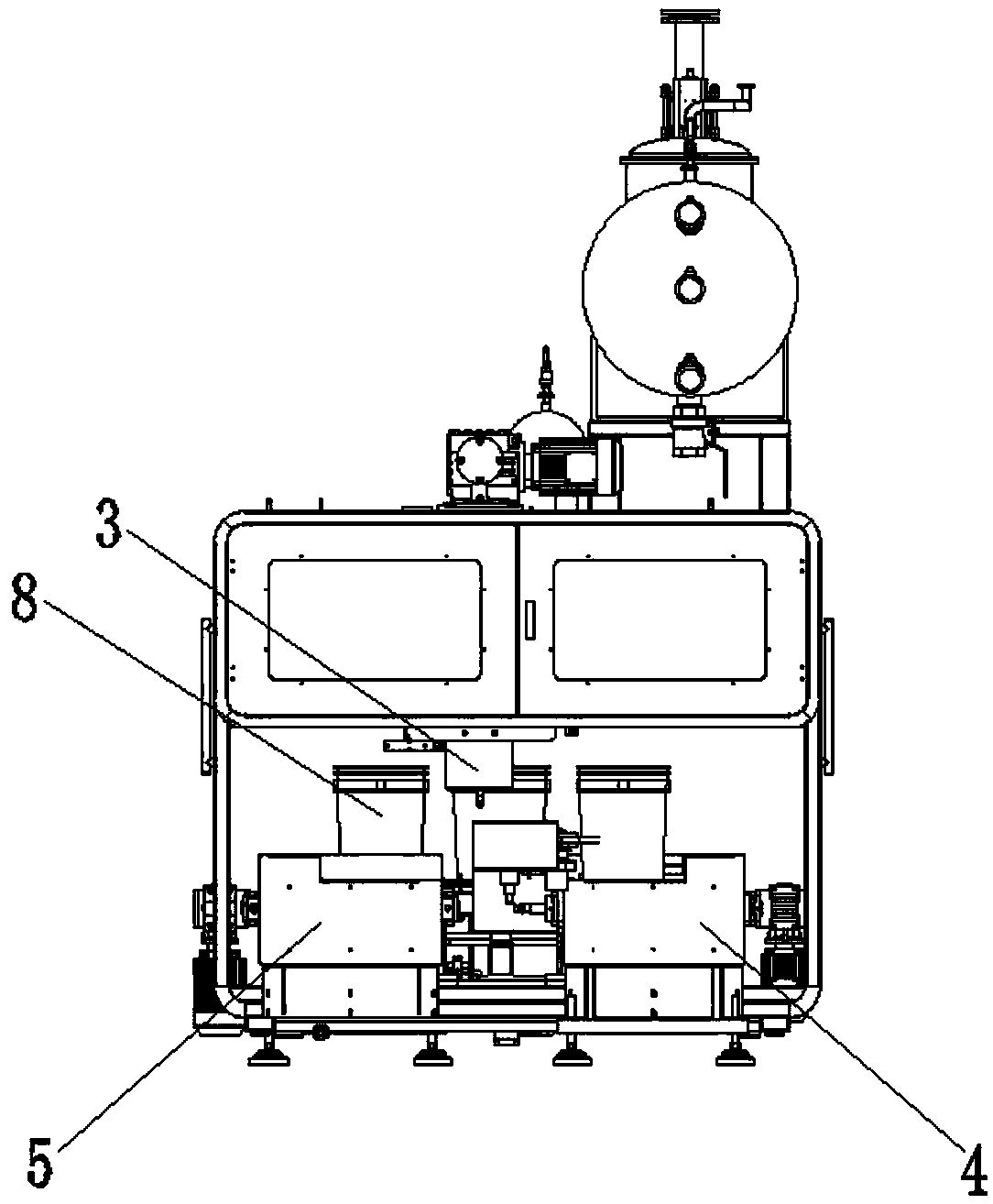

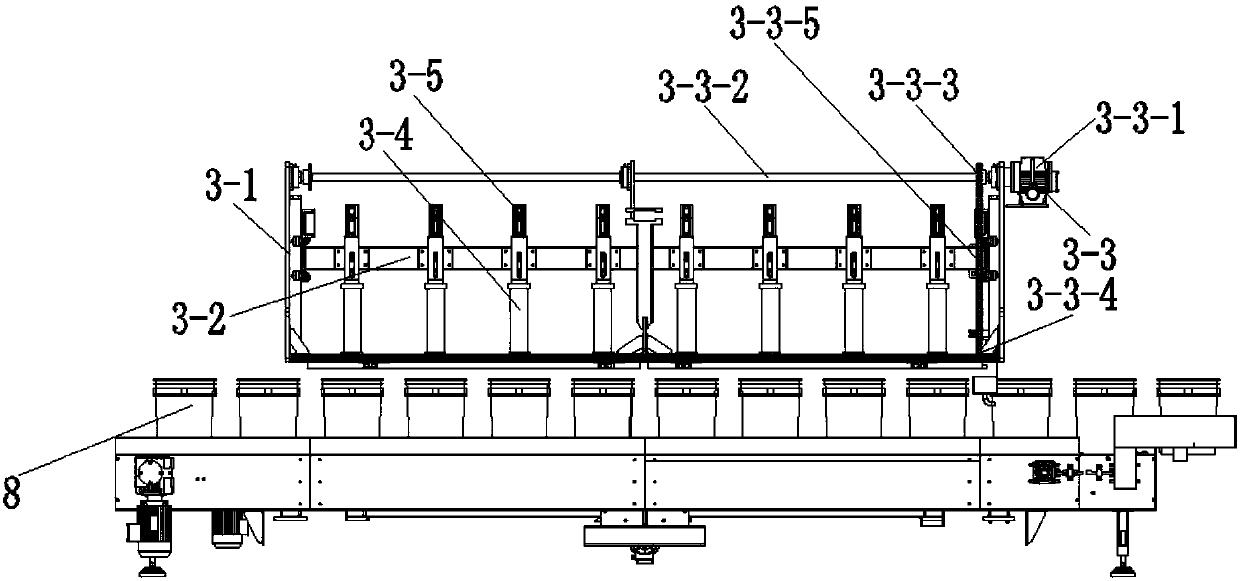

Three-row weighing and filling machine

PendingCN107814001AIncrease the number ofReduce replacement timeLiquid materialElectrical and Electronics engineeringMechanical engineering

The invention discloses a three-row weighing and filling machine comprising a cabinet, a material tank, a material filling mechanism, a container feed-in mechanism, a container send-out mechanism, a weighing and material filling platform and a container push mechanism. The material tank is fixed to the top of the cabinet. The material filling mechanism is arranged in the cabinet and communicates with the material tank. The container feed-in mechanism penetrates in from one side of the cabinet, and the container send-out mechanism penetrates out from the other side of the cabinet. The weighingand material filling platform is arranged in the cabinet, located between the container feed-in mechanism and the container send-out mechanism and located under the material filling mechanism at the same time. The container push mechanism is arranged in the cabinet and pushes containers to move between the container feed-in mechanism, the weighing and material filling platform and the container send-out mechanism. By means of the three-row weighing and filling machine, the number of the containers where material filling is conducted each time can be greatly increased, and meanwhile all the containers are sent out at the same time; and the container replacement time is greatly shortened, and therefore the filling efficiency is greatly improved.

Owner:江苏汤姆森智能装备有限公司

Bathing mat, water heater and bathing system

The invention provides a bathing mat, a water heater and a bathing system. According to the bathing mat, the water heater and the bathing system, external pressure generated by a user is sensed, a sensing value is generated, and an external pressure value is calculated according to the sensing value; and user identity of the user is recognized according to the external pressure value, and corresponding user habit parameters are determined according to the user identity. According to a method, the user identity can be recognized, thus the corresponding user habit parameters are determined, andthe automated demands are met.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD +1

Strip-material automatic feeding equipment matched with punching machine for using

InactiveCN106734702AReduce labor intensityReduce labor costsMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention discloses strip-material automatic feeding equipment matched with a punching machine for using. The strip-material automatic feeding equipment comprises an equipment support and an automatic feeding device arranged on one side of the equipment support, an automatic arrangement device is connected to the automatic feeding device, and an automatic taking and putting device is arranged on one side of the automatic feeding device. A storing table is arranged on the discharging end of the automatic feeding device, a work control device is arranged on the equipment support, and a control port of the work control device is connected with communication ports of the automatic feeding device and the automatic taking and putting device. Therefore, automatic feeding and taking are achieved, the labor intensity of workers is lowered, manual cost is reduced, and production efficiency is improved. A better storing plan is possessed, the specification of a multi-grid tray can be adjusted, and the storing requirement of all kinds of strip materials can be met.

Owner:江苏冠达通电子科技有限公司

Deformable nail frame for carpet forming die

PendingCN111286903AReduce the size of scrapReduce carpet costsHeating/cooling textile fabricsStructural engineeringWaste material

The invention relates to a deformable nail frame for a carpet forming die. The carpet forming die comprises an upper die and a lower die, wherein a surface carpet is bound on the nail frame; the nailframe is arranged between the upper die and the lower die; the nail frame is pressed down by the upper die and the nail frame and the lower die oppositely move during clamping; the nail frame comprises an outer frame and an inner frame; the inner frame is arranged at the inner side of the outer frame; a plurality of pegs are uniformly distributed on the inner frame; the surface carpet is bound onthe nail frame through the pegs; and the inner frame is divided into two halves, wherein one half is a deformable inner frame and the other half is a fixed inner frame, or both the two halves are deformable inner frames. The deformable nail frame is reasonable in design and simple in structure, and is kept horizontal when a fabric is pressed, so as to meet the automation requirement; and when thecarpet is formed, the deformable nail frame deforms and is consistent with the contour of the lower die, so that the size of waste is reduced and the cost of the carpet is reduced.

Owner:JIANGSU HAN GAO MACHINERY CO LTD

A method of using a multi-layer storage rack

ActiveCN102744721BHigh degree of automationImprove loading and unloading efficiencyWork tools storageEngineeringMultiple layer

The invention discloses a multi-layer storage material rack, which comprises trays arranged in multiple layers up and down. The tray is installed on the column of the multi-layer storage material rack. The column is channel steel, and the tray is installed on the two sides of the channel steel through pin shafts. The pin shaft divides the pallet into two parts of unequal length; the bottom surface of the channel steel is provided with a pallet limit hole corresponding to the pallet, and when the pallet is in a horizontal state, one end of the longer part sticks out to hold the material; One end of the short part is in contact with the upper edge of the pallet limit hole; two adjacent pallets up and down are connected by a pallet connector, and the connecting part is set on the shorter part of the pallet; a load-bearing block is arranged on the pallet connector. Adopting the above-mentioned technical solution, the cost of manufacturing and using is low, durable, and easy to use; it expands the scope of application, avoids the constraints of traditional pneumatic devices, meets the needs of machine automation, and significantly improves the loading and unloading efficiency of logistics equipment.

Owner:芜湖中山科技有限公司

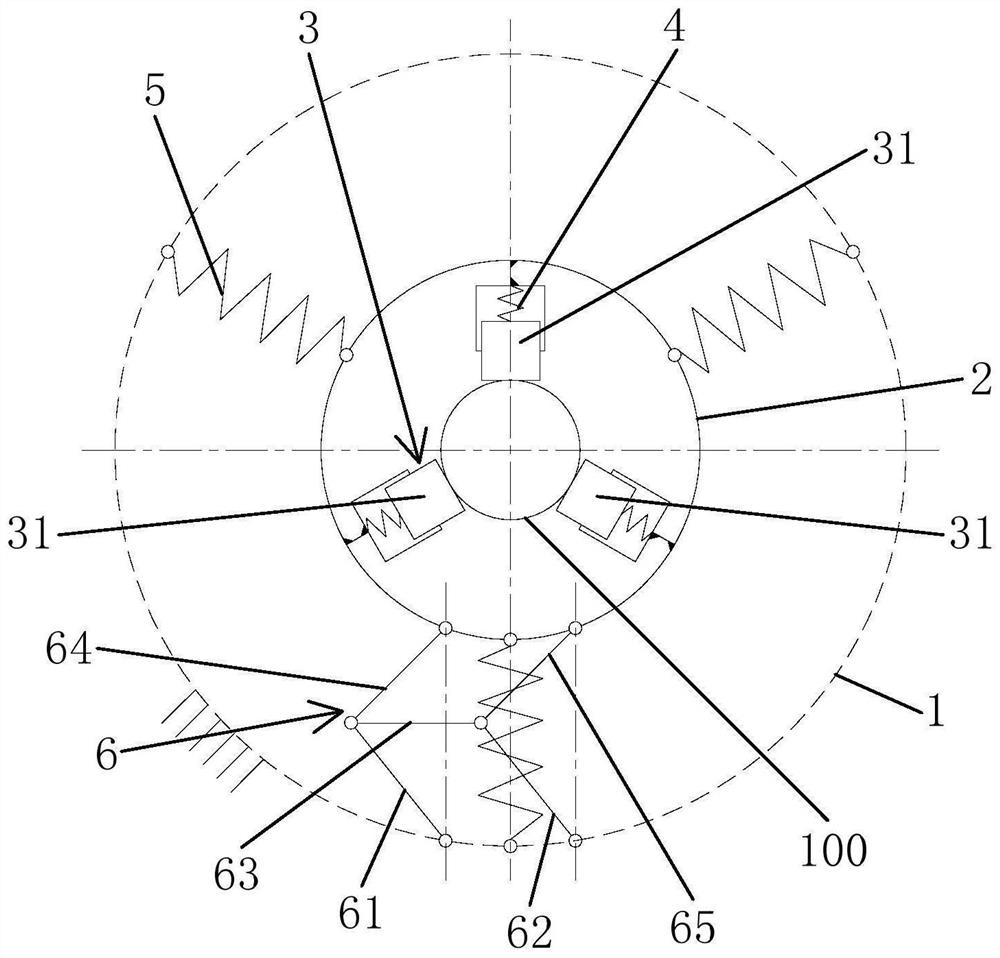

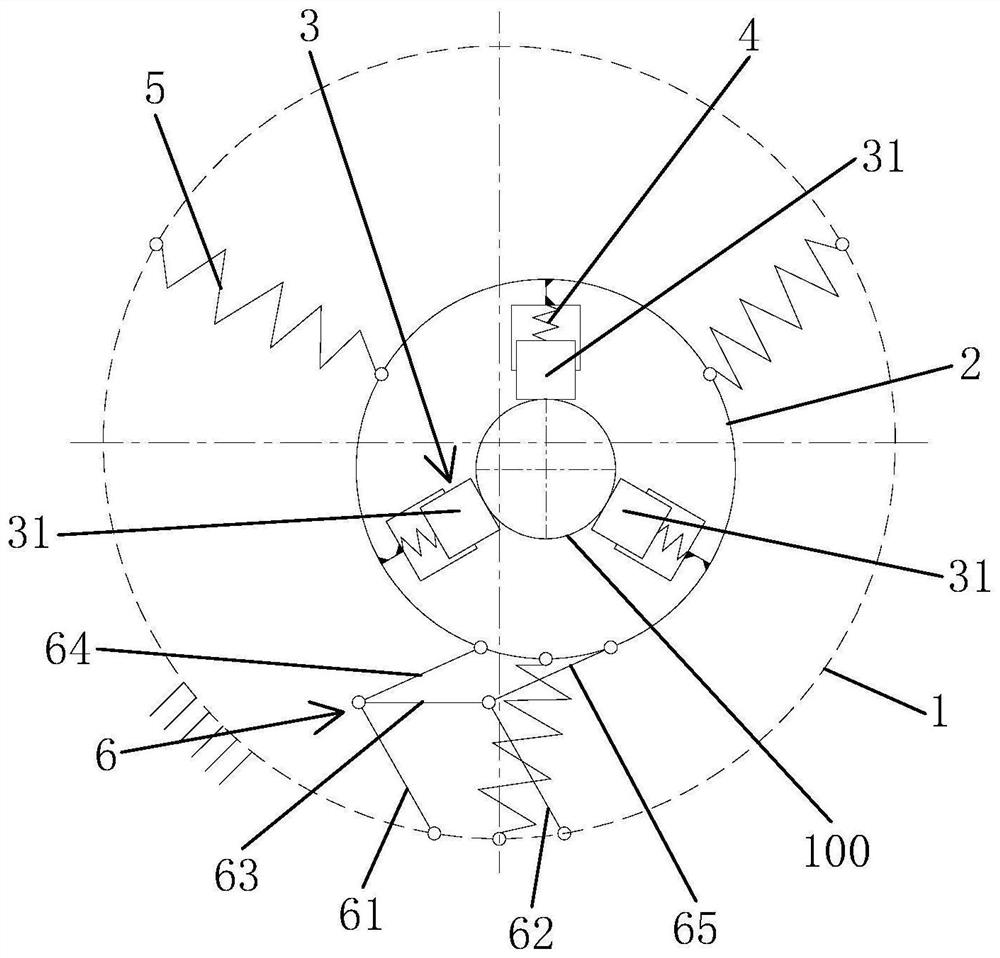

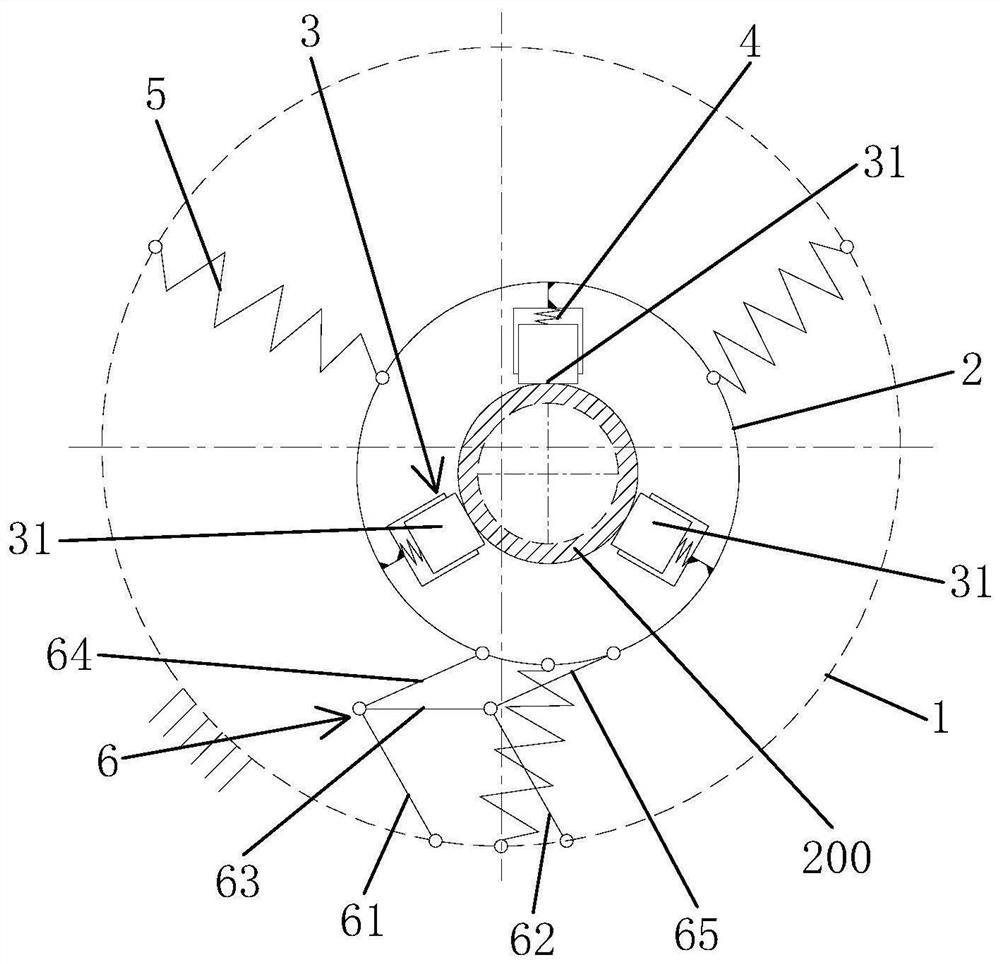

Intelligent clutch edge-hair-free treatment device

PendingCN108857670AAvoid wear and tearExtended service lifeEdge grinding machinesGrinding drivesImpellerGrind

The invention discloses an intelligent clutch edge-hair-free treatment device, and belongs to the field of clutch piece processing. According to the technical scheme, the intelligent clutch edge-hair-free treatment device is characterized by including a device main body, a selecting mounting platform, and a diamond grinding head; the selecting mounting platform is fixedly mounted on the outer wallof the device main body, a burr removing seat grind is movably mounted on the upper wall of the selecting mounting platform, and an automatic rotating bottom disc is movably mounted above the burr removing seat grind; and the diamond grinding head is fixedly mounted above the burr removing seat grind. According to the intelligent clutch edge-hair-free treatment device, an impeller is adopted, a clutch piece can be made to rotate at the high speed, the primary burr removing is conducted, the clutch piece is thrown above the diamond grinding head, and once grinding for multiple pieces is achieved; the automatic rotating bottom disc is arranged below the diamond grinding head, and the diamond grinding head can be made to rotate automatically, so that the effect of efficient burr removing isachieved; and an intelligent speed setting valve is arranged, the function of intelligent speed adjustment is achieved, and the chips can be processed by arranging a dust sucking hose.

Owner:绍兴上虞恒发摩配厂

Automatic breast density grading method and device

InactiveCN109636780AImprove accuracyImprove efficiencyImage enhancementImage analysisClassification methodsBreast density

The invention provides an automatic breast density grading method and device. The method comprises: acquiring a target breast X-ray image; preprocessing the target mammary gland X-ray image; and taking the preprocessed target mammary gland X-ray image as a prediction sample, inputting the prediction sample into a preset target depth residual error network, and taking the output of the target depthresidual error network as a mammary gland density grading result corresponding to the target mammary gland X-ray image. The breast density classification method and device can effectively improve theaccuracy and efficiency of feature recognition of the mammary gland X-ray image, can effectively and reliably improve the high efficiency and intelligent degree of the classification process of the mammary gland density corresponding to the mammary gland X-ray image, and can effectively improve the accuracy of mammary gland density classification.

Owner:SHENZHEN INST OF ADVANCED TECH

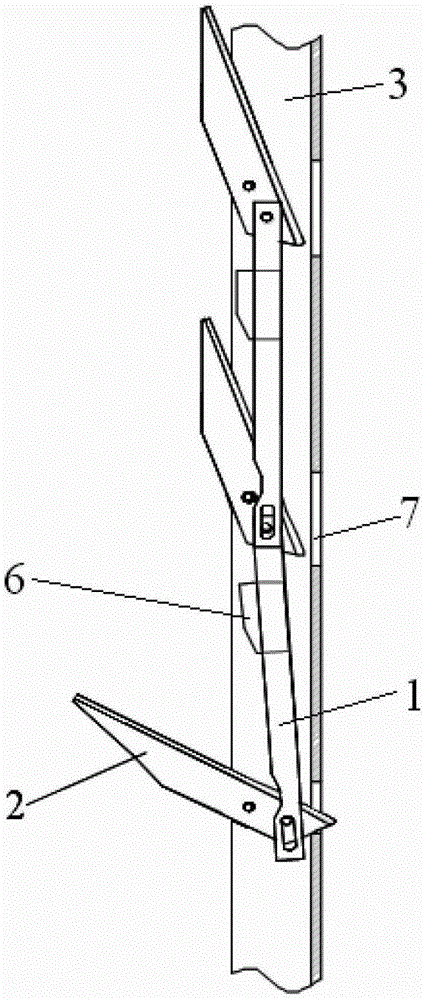

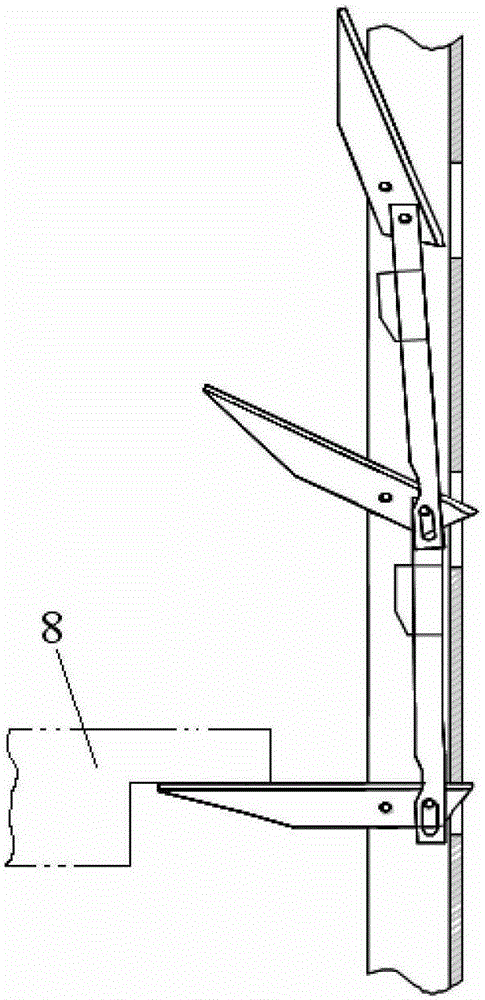

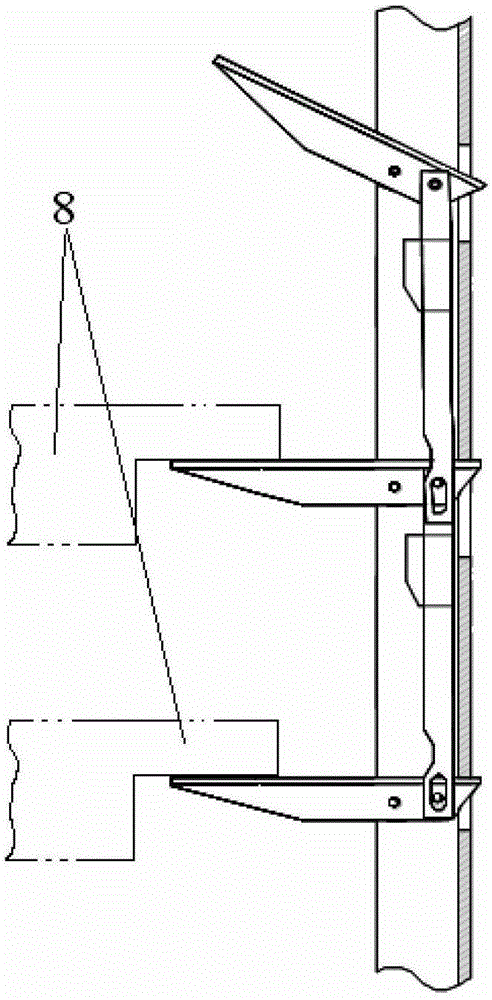

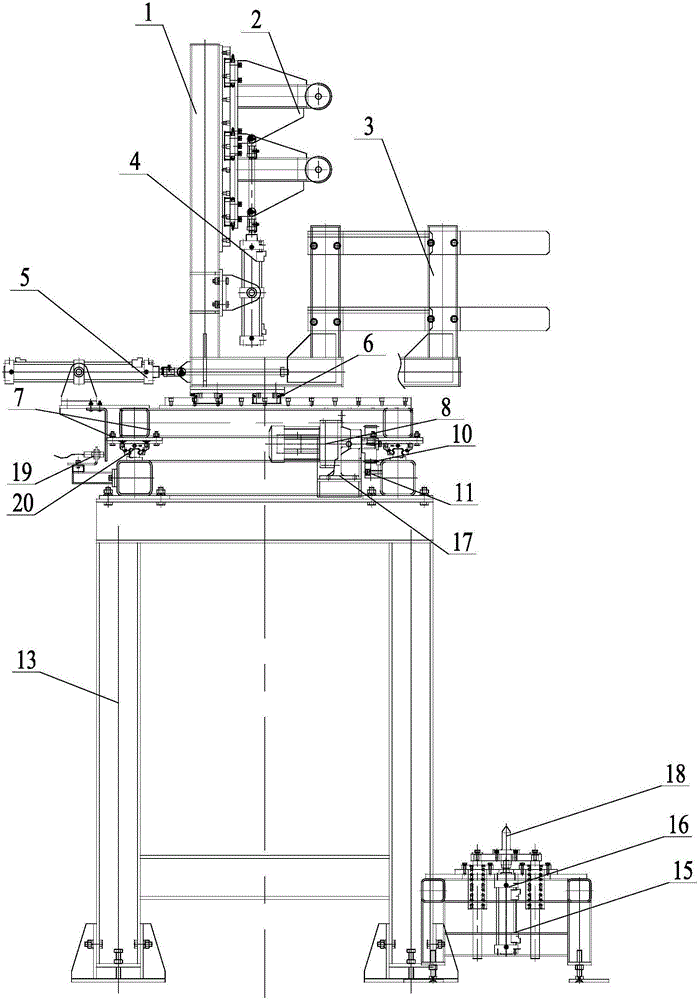

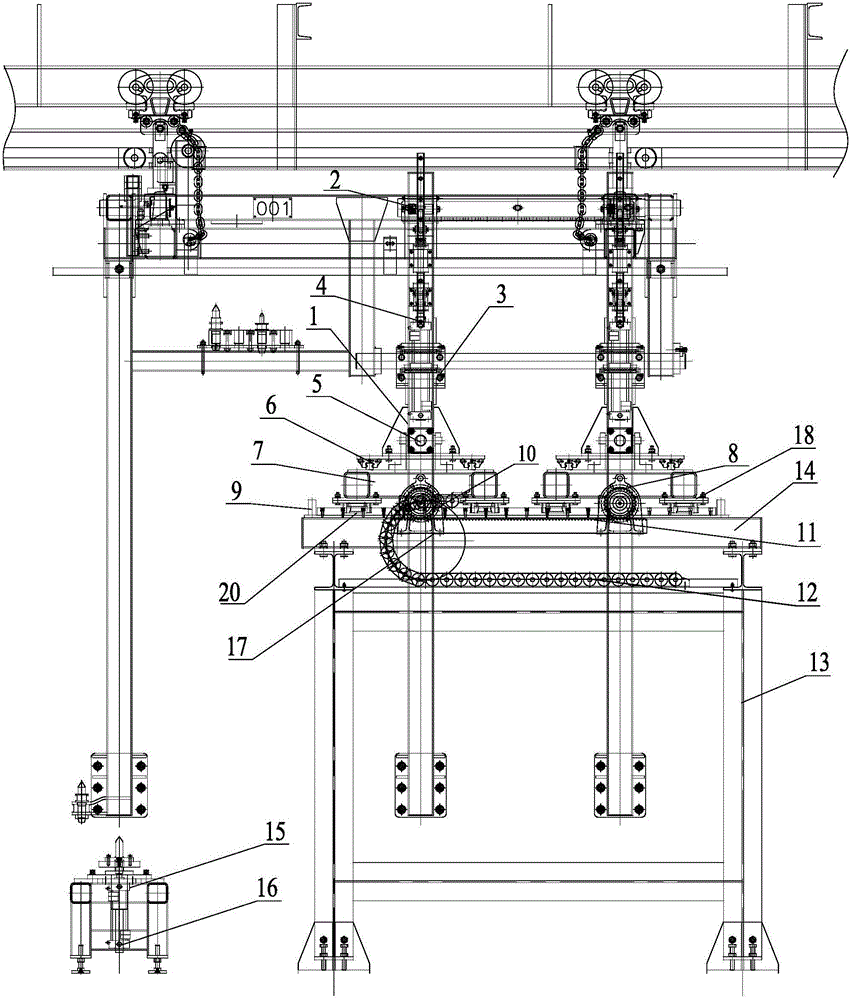

Rear support and adjustment device of sling

ActiveCN106044531AMeeting Automation NeedsCompact structureLoad-engaging elementsLow noiseEngineering

The invention belongs to the technical field of conveyors, and relates to a rear support and adjustment device of a sling. The rear support and adjustment device comprises a bottom frame, wherein a lower rack is arranged on the upper part of the bottom frame, a sliding mechanism is arranged on the upper part of the lower rack in a matched manner, a second linear sliding rail and a rack are arranged on the lower rack, the sliding mechanism is arranged on the second linear sliding rail in a sliding mode, and a gear and a rack in the sliding mechanism are engaged; a first linear sliding rail is arranged on the top of the sliding mechanism, the arrangement direction of the first linear sliding rail is perpendicular to that of the second linear sliding rail, a horizontal air cylinder is fixed to the rear end of the top of the sliding mechanism, a climbing mechanism is arranged on the first linear sliding rail in a sliding mode, and the climbing mechanism is fixedly connected with a piston rod of the horizontal air cylinder. By virtue of the engagement and transmission of the gear and the rack and the control of the air cylinder, the rear support and adjustment device has the advantages of compact structure, wide adjustment range, high speed, simplicity in control, low noise, high adjustment accuracy, reliable performance and high degree of automation, and the automation requirement of modern logistics transportation can be effectively satisfied.

Owner:MIRACLE AUTOMATION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com