Strip-material automatic feeding equipment matched with punching machine for using

An automatic feeding and equipment technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as reducing equipment reliability, labor intensity of workers, and easy connection problems, so as to meet the needs of automation and reduce Labor intensity of workers and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

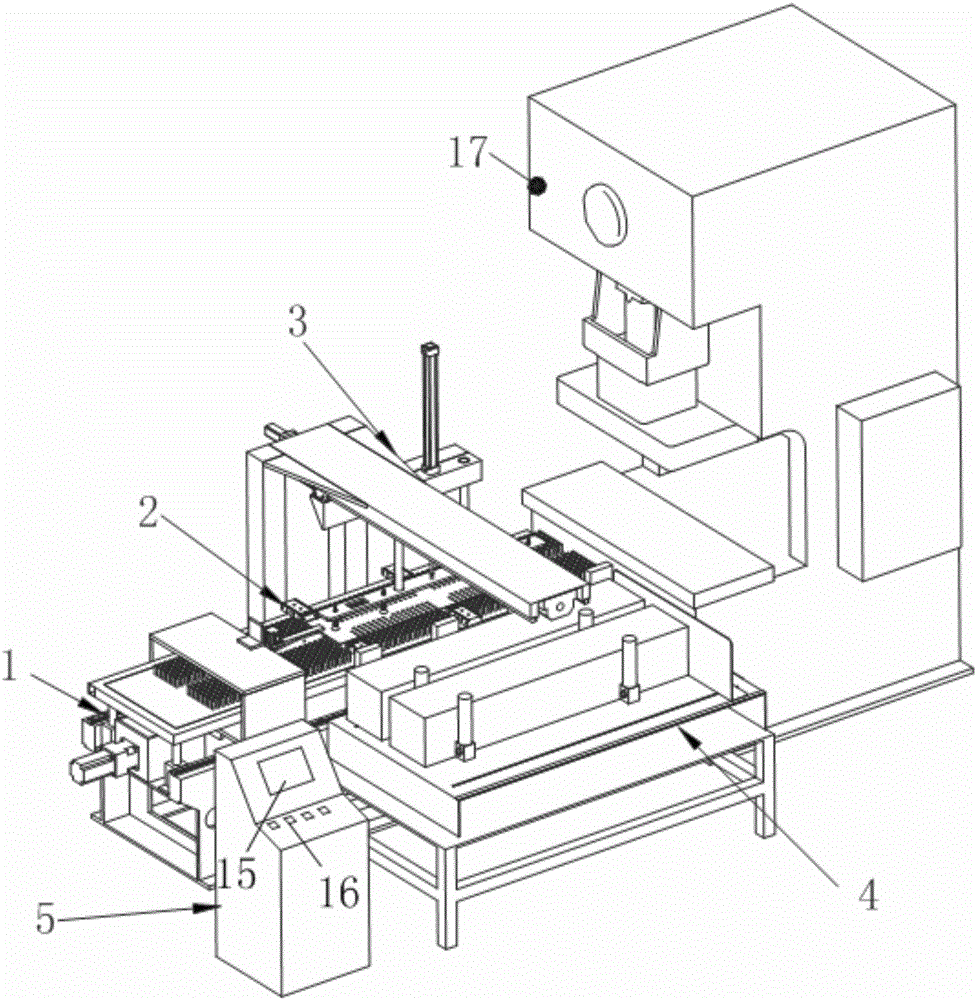

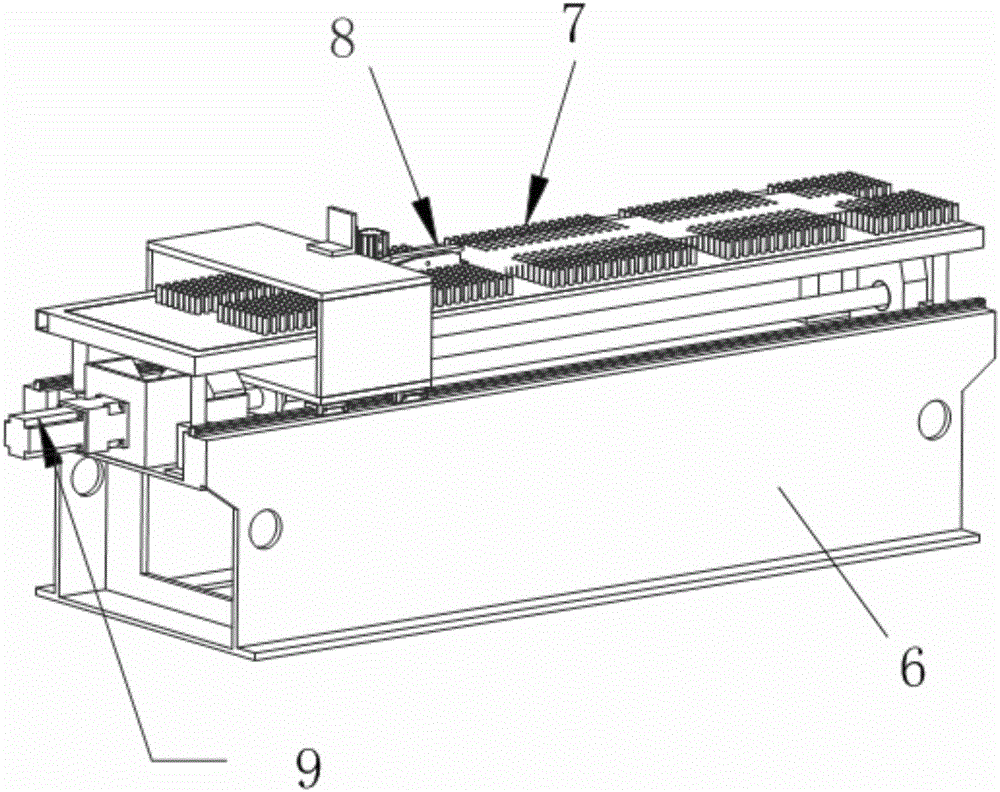

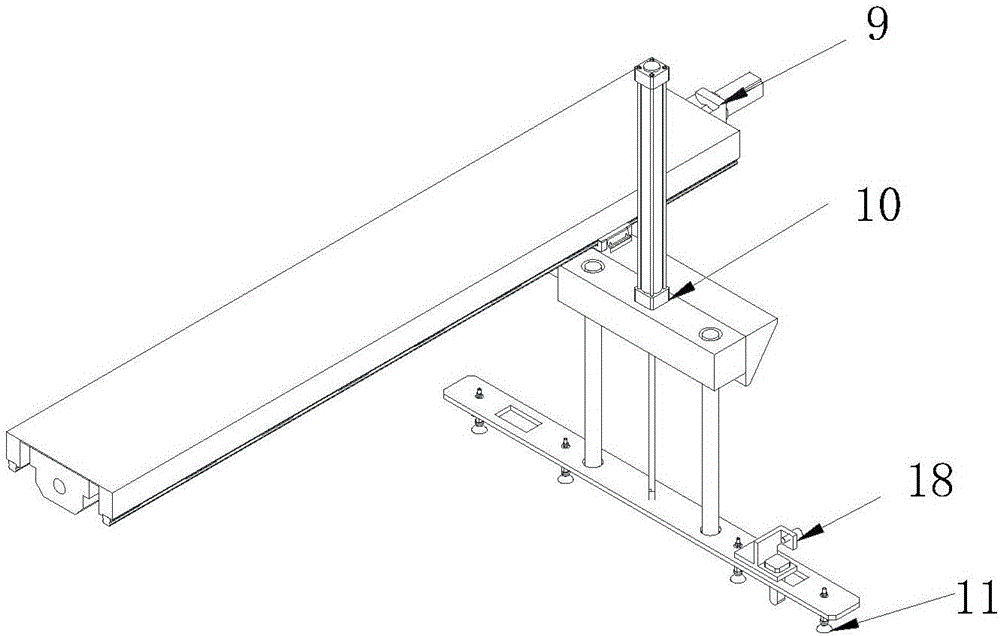

[0028] Example: such as Figure 1~4 The strip automatic feeding equipment used with the punching machine shown is equipped with an equipment bracket. It is different in that: in order to meet automatic feeding, an automatic feeding device 1 is provided on one side of the equipment bracket. Simultaneously, in consideration of realizing effective strip material arrangement, an automatic material finishing device 2 is connected to the automatic feeding device 1 , and an automatic feeding device 3 is provided on one side of the automatic feeding device 1 . Moreover, in order to meet the requirements of over-station processing, a storage table 4 is provided at the discharge end of the automatic feeding device 1 . Considering the convenience of automatic control, an industrial control device 5 is installed on the equipment support, and the control ports of the industrial control device 5 are connected with the communication ports of the automatic feeding device 1 and the automatic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com