Granulating equipment for preparing hydrotalcite chewable tablets and production process of hydrotalcite chewable tablets

A technology of aluminum magnesium carbonate and chewable tablets, which can be used in lighting and heating equipment, active ingredients of aluminum/calcium/magnesium, and devices that make medicines into special physical or ingestible forms, and can solve problems such as the inability to detect the dryness of materials , to achieve the effect of low cost, strong moisture absorption capacity and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

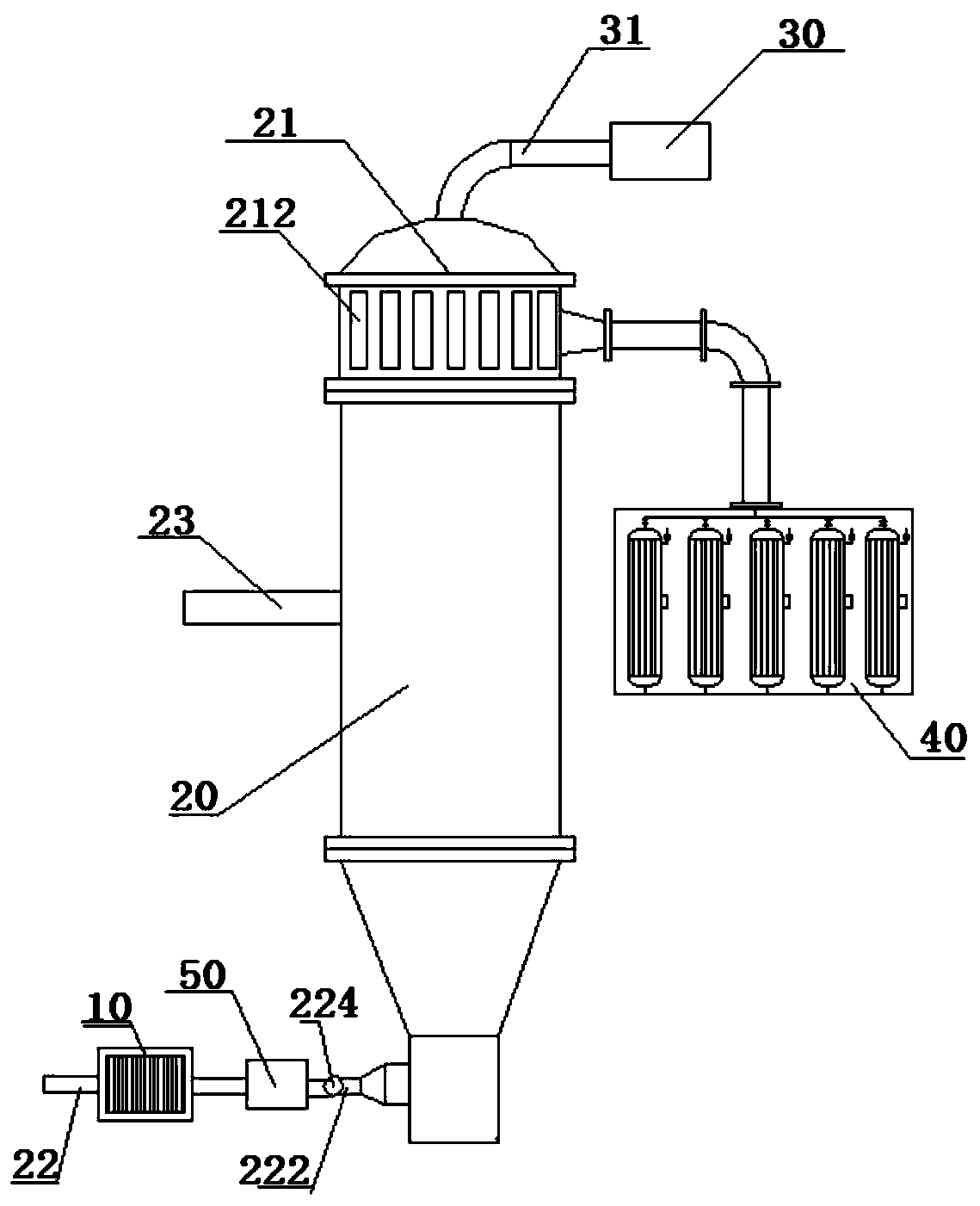

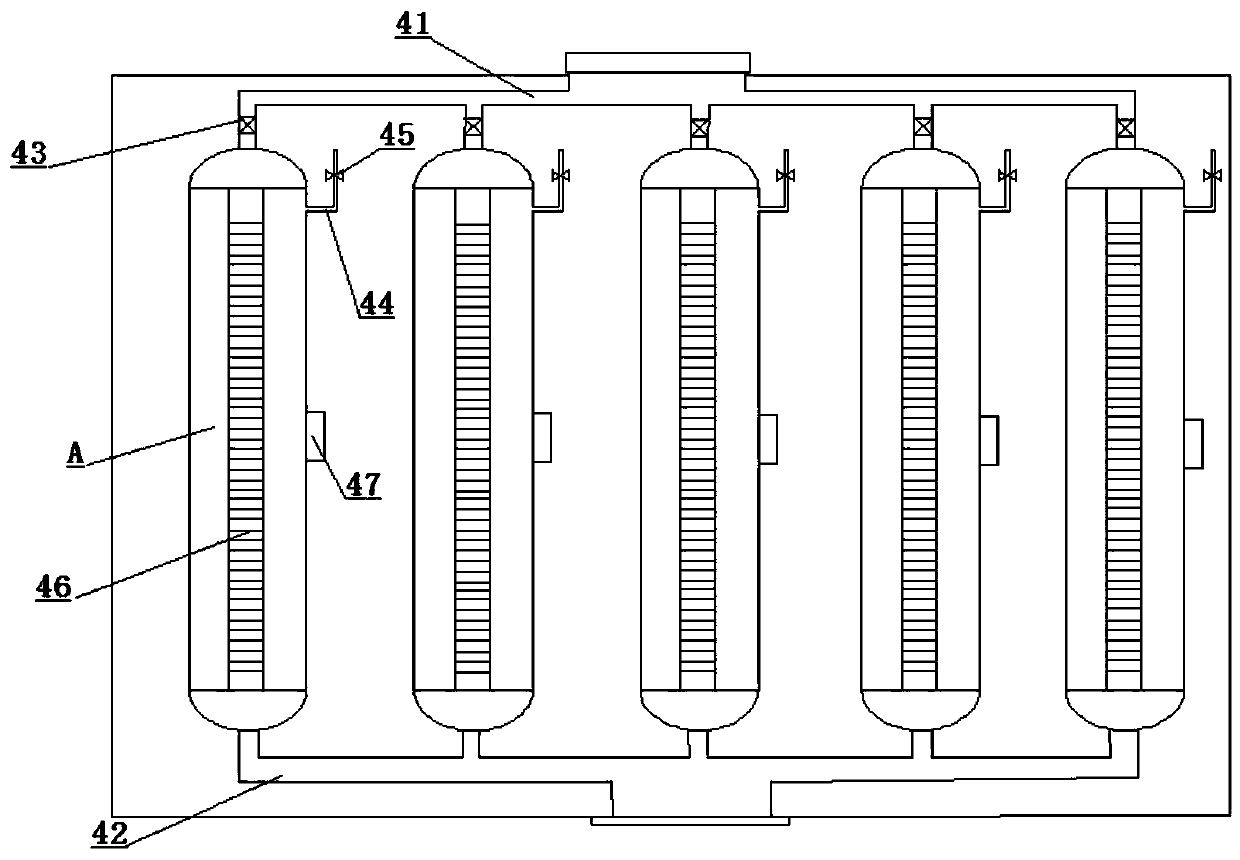

[0035] Please refer to figure 1 , figure 1 It is a structural schematic diagram of the fluidized dryer described in Example 1 of the present invention.

[0036] A boiling dryer for preparing hydrotalcite chewable tablets, which includes a heater, a drying host, an induced draft fan, a humidity detection device and a controller (not shown).

[0037] The upper part of the drying host is provided with an air outlet, which is connected to the induced draft fan through an air duct. The outlet is provided with a bag filter; the middle part of the drying host is provided with a material inlet; the lower part of the drying host is provided with an air inlet. The air inlet is connected to the heater through an air inlet pipe, and an air volume regulating valve is also arranged on the air inlet pipe; a filter is also included, which is connected to the heater through a pipe.

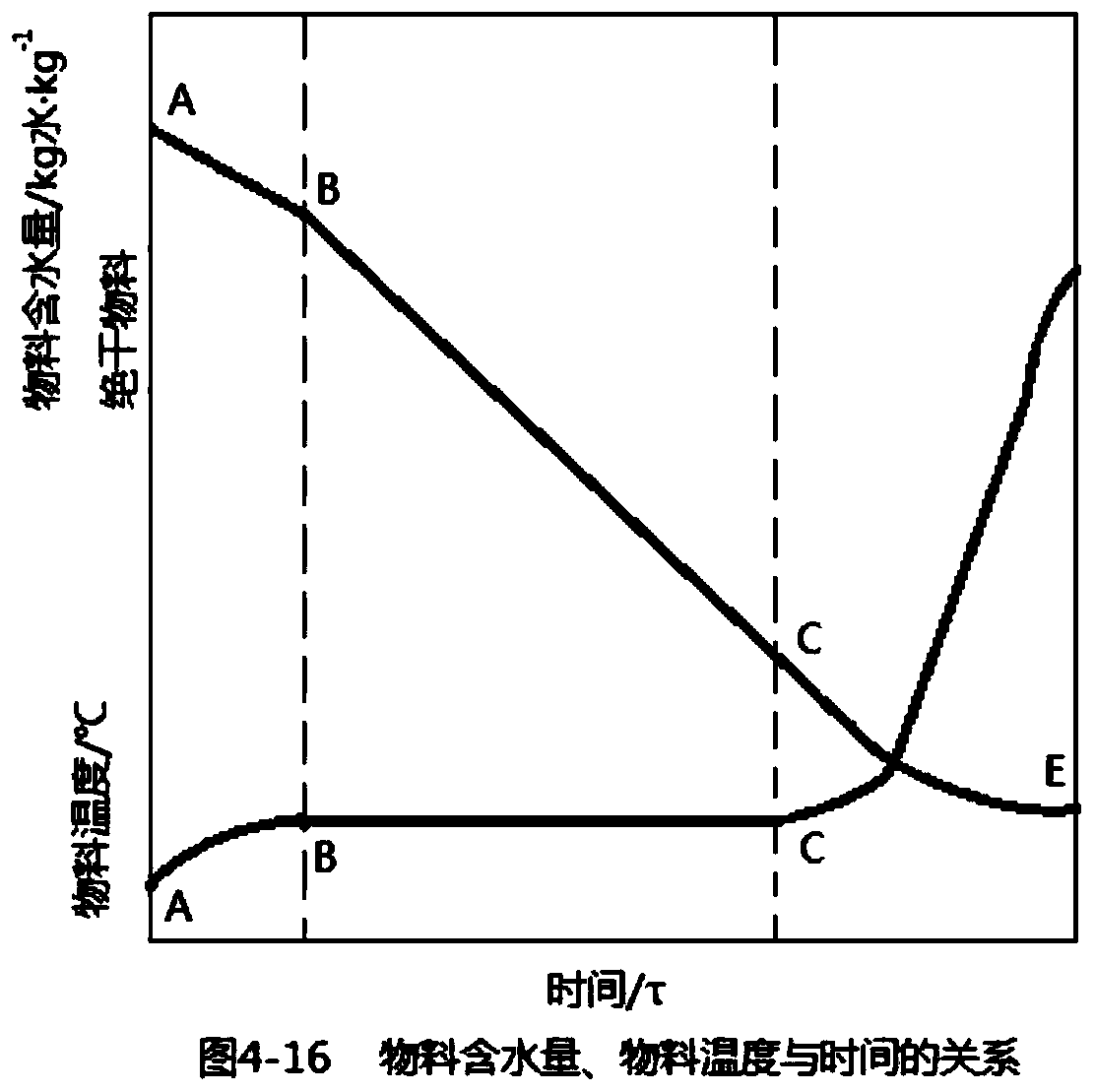

[0038]The controller is electrically connected to the heater, the induced draft fan, and the humidity detecti...

Embodiment 2

[0058] In this example, the structure of the boiling drier for preparing hydrotalcite chewable tablets is basically similar to that in Example 1, the only difference is that in this example, the humidity detection device only contains a color-changing silica gel desiccant Drying device.

[0059] Compared with the prior art, the boiling drier for the preparation of aluminum magnesium carbonate provided by the present invention utilizes the characteristics of the color-changing silica gel desiccant to absorb water and change color after absorbing water, and can detect the degree of discoloration of the desiccator through color detection. Moisture detection is carried out quantitatively by wind, and then the drying degree of the material in the dryer is detected; by comparing the detection signal with the preset value, the drying end point can be judged and the work of the dryer can be automatically controlled. The device is simple, the cost is low, and the detection is accurate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com