Printing production control and early-warning system

A production control and early warning system technology, applied in the complete banking system, complete banking system, instruments, etc., can solve the problems of high threshold, high implementation cost, difficult technical implementation, etc., and achieve the effect of control and early warning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

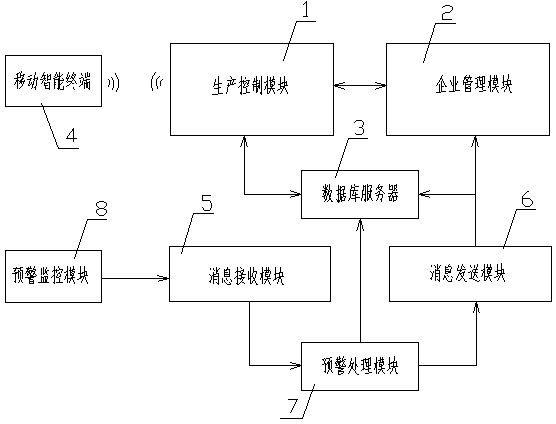

[0023] Such as figure 1 As shown, the printing production control and early warning system of the present invention includes a mobile intelligent terminal 4, a production control module 1, an enterprise management module 2, a database server 3, an early warning processing module 7, an early warning monitoring module 8, a message receiving module 5 and a message sending module 6 , the production control module 1 and the enterprise management module 2 perform synchronous data transmission in real time to keep the update of the order production progress and status, and the mobile intelligent terminal 4 collects workload and progress information in real time and transmits the information to the Production control module 1, the production control module 1 saves data and shares information with the enterprise management module 2 through the database server 3, the early warning monitoring module 8 monitors the production process, and reports sudden accidents and possible occurrences ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com