Firework gunpowder mixing device

A mixing device and gunpowder technology, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve problems such as difficulty in precise control and inability to achieve production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

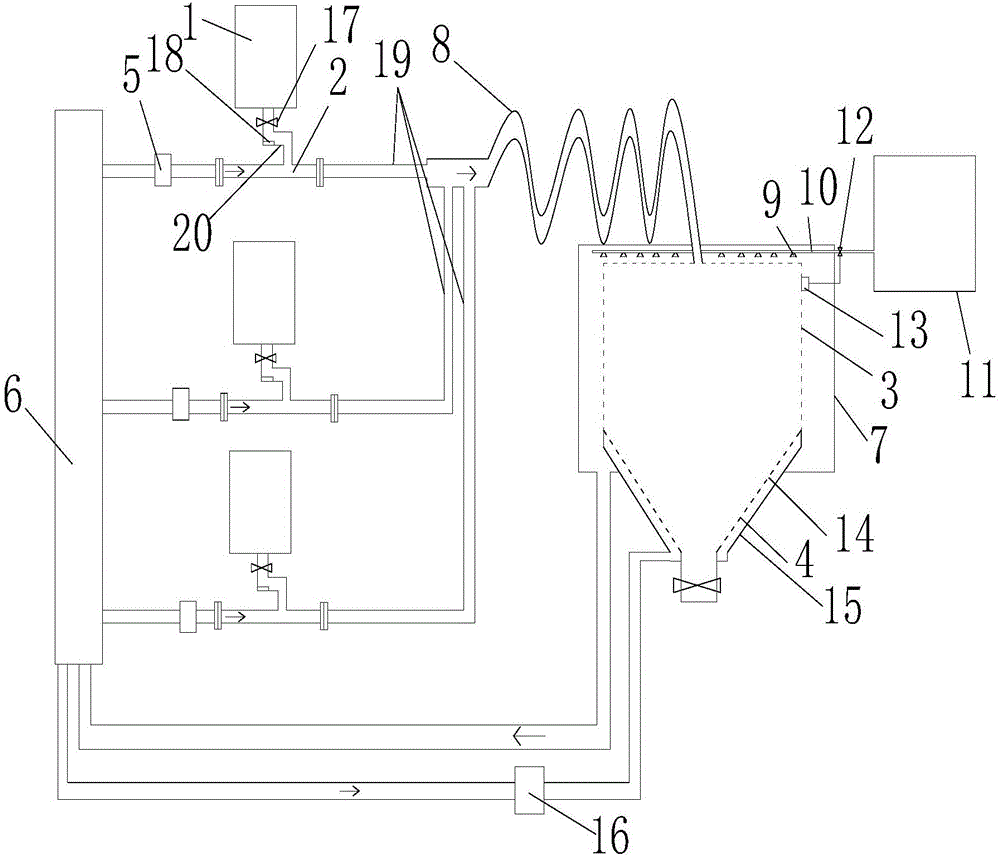

[0022] The technical solutions of the present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

[0023] Such as figure 1 Shown includes a stocker 1, a control module, a feeding system and a mixing device 3, wherein the feeding system is composed of an air amplifier and a delivery pipeline, and the stocker 1 communicates with the air amplifier 2 of the feeding system And feeding in the ventilation mixing device 3, the mixing device 3 is provided with ventilation holes 14. In the present invention, the air amplifier 2 is used to blow the material in the stocker 1 to the mixing device 3 through the feeding system for mixing. Since the feeding system includes a feeding pipe for feeding, and the material is transported through the feeding pipe 19, the problem that the conveyor belt and the like cannot adapt to complex terrains and the cost is high is overcome. At the same time, due to the use of air blowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com