Incubation chamber and wrapped moving incubation device

An incubator and incubator technology, applied to laboratory appliances, shells or chambers, heating or cooling equipment, etc., can solve the problems of temperature difference, inconvenient use, inconsistent reaction, etc., to avoid heat loss, Guarantee the effect of accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

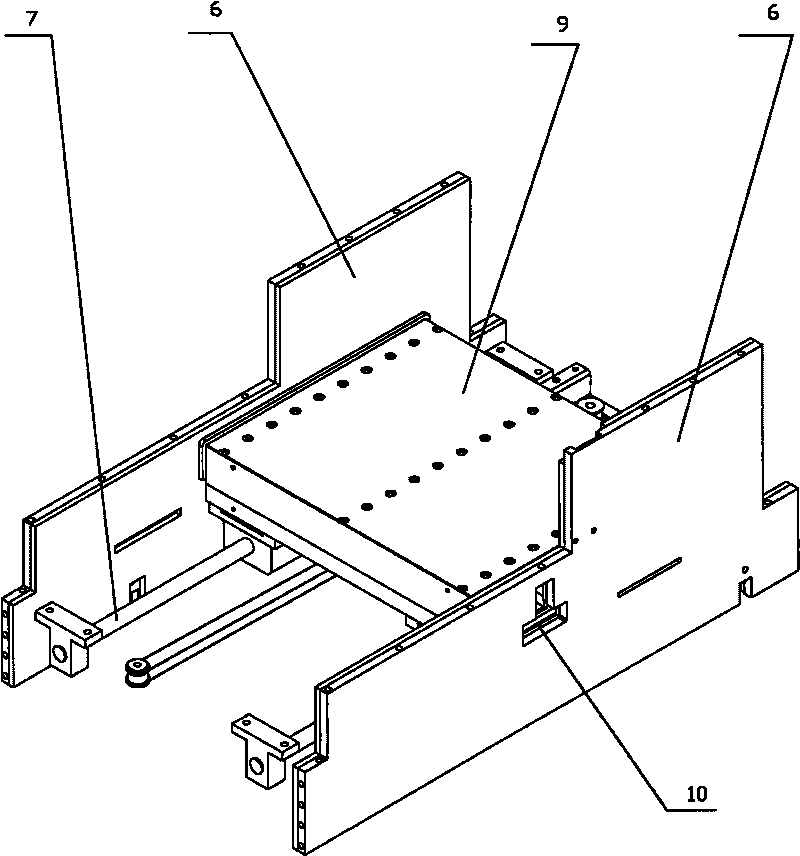

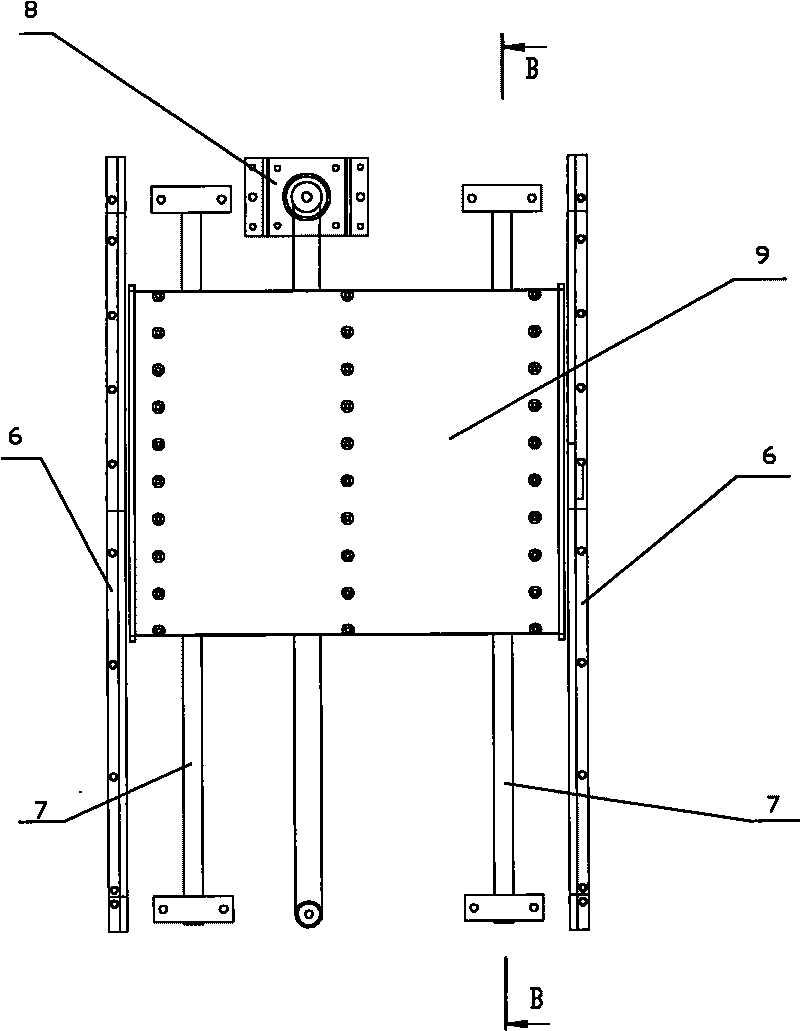

[0034] The containment movement type incubation device of the present invention comprises an incubation chamber 9 and guide rail 7, and described incubation chamber 9 can move along guide rail 7, and incubation chamber 9 of the present invention is connected with synchronous motor 8, and guide rail 7 is arranged on the bottom of incubation chamber 9, by The synchronous motor 8 drives the incubation chamber 9 to move on the guide rail 7 . Therefore, exercise is added while incubating, so that the contents of the cuvette can be fully contacted and the reaction is more complete.

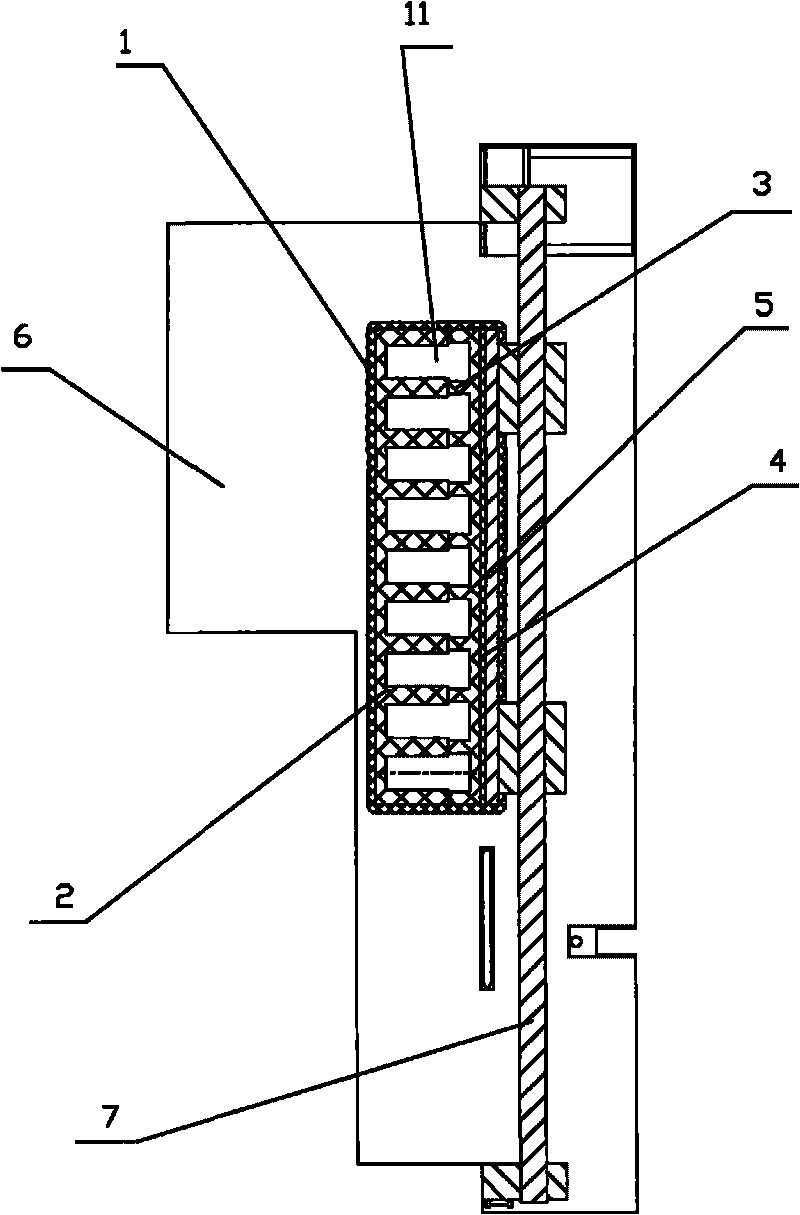

[0035] The incubation chamber 9 of the present invention includes an incubation tray 3 for placing a reaction cup 11, an electric heating film 4 located under the incubation tray 3, an incubation cover plate 2 on the reaction cup 11 and an external insulation layer 1, an incubation tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com