Fluidized return mining structure and method suitable for deep coal resources

A fluidization and resource technology, which is applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of leaving too many coal pillars, low recovery rate, high cost of shaft construction and maintenance, and reduce the cost of tunnel construction. Quantity, high recovery rate, and the effect of reducing construction and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

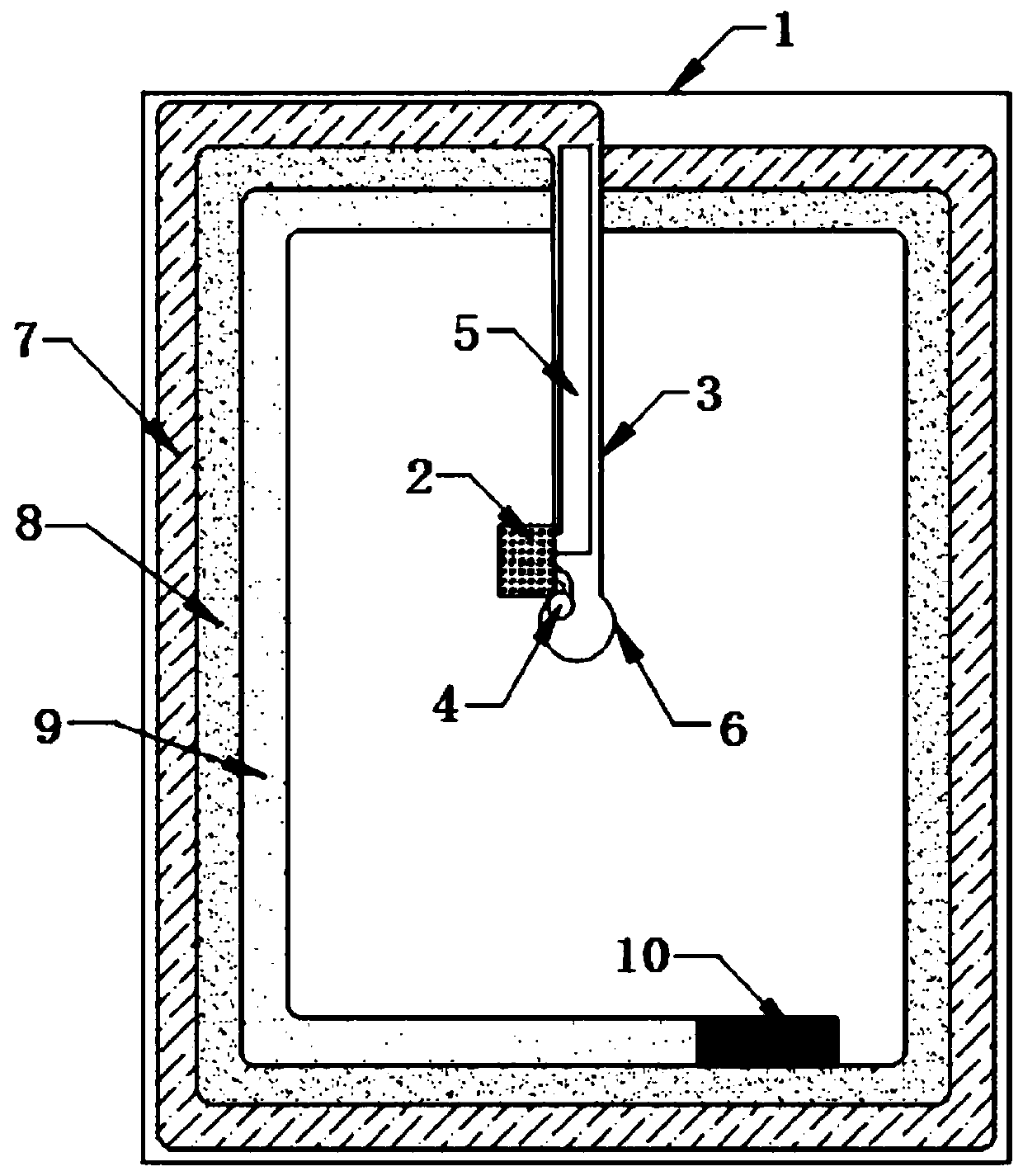

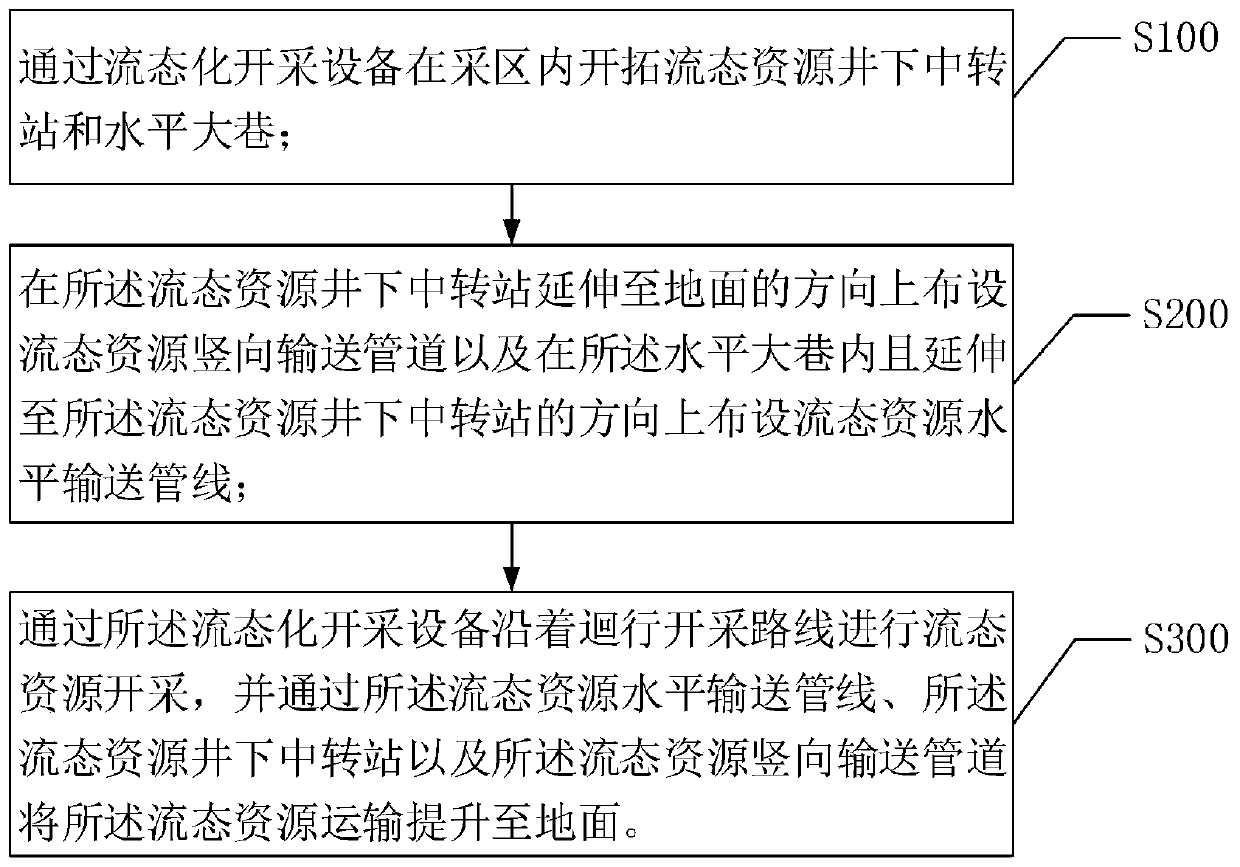

[0024] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0025] Due to the traditional coal mining method, in order to transport and upgrade coal, power supply, equipment supply, etc., multiple shafts, a large number of roadways and underground transfer stations for fluid resources are excavated. This mining method not only has a large amount of roadway excavation, high cost of roadway construction and maintenance, many coal pillars, and low recovery rate, it is not suitable for fluidized mining of deep coal resources. In order to solve the above problems, the present invention provides a fluidized return mining structure suitable for deep coa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap