Valve plate assembly capable of accurately adjusting temperature and valve core capable of accurately adjusting temperature

A valve plate, precise technology, applied in the direction of sliding valve, multi-port valve, valve device, etc., can solve the problems of small rotation angle of the moving valve plate, inconvenient adjustment, difficult to adjust the temperature of the outlet water, etc., to achieve the effect of increasing the rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1, a valve plate assembly capable of precise temperature adjustment,

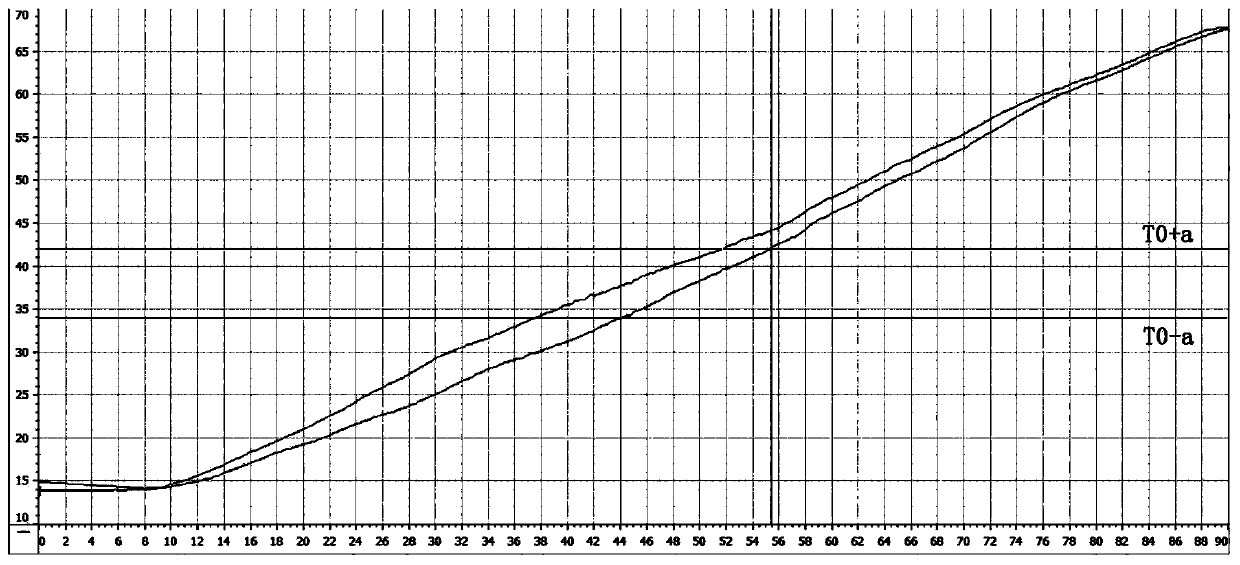

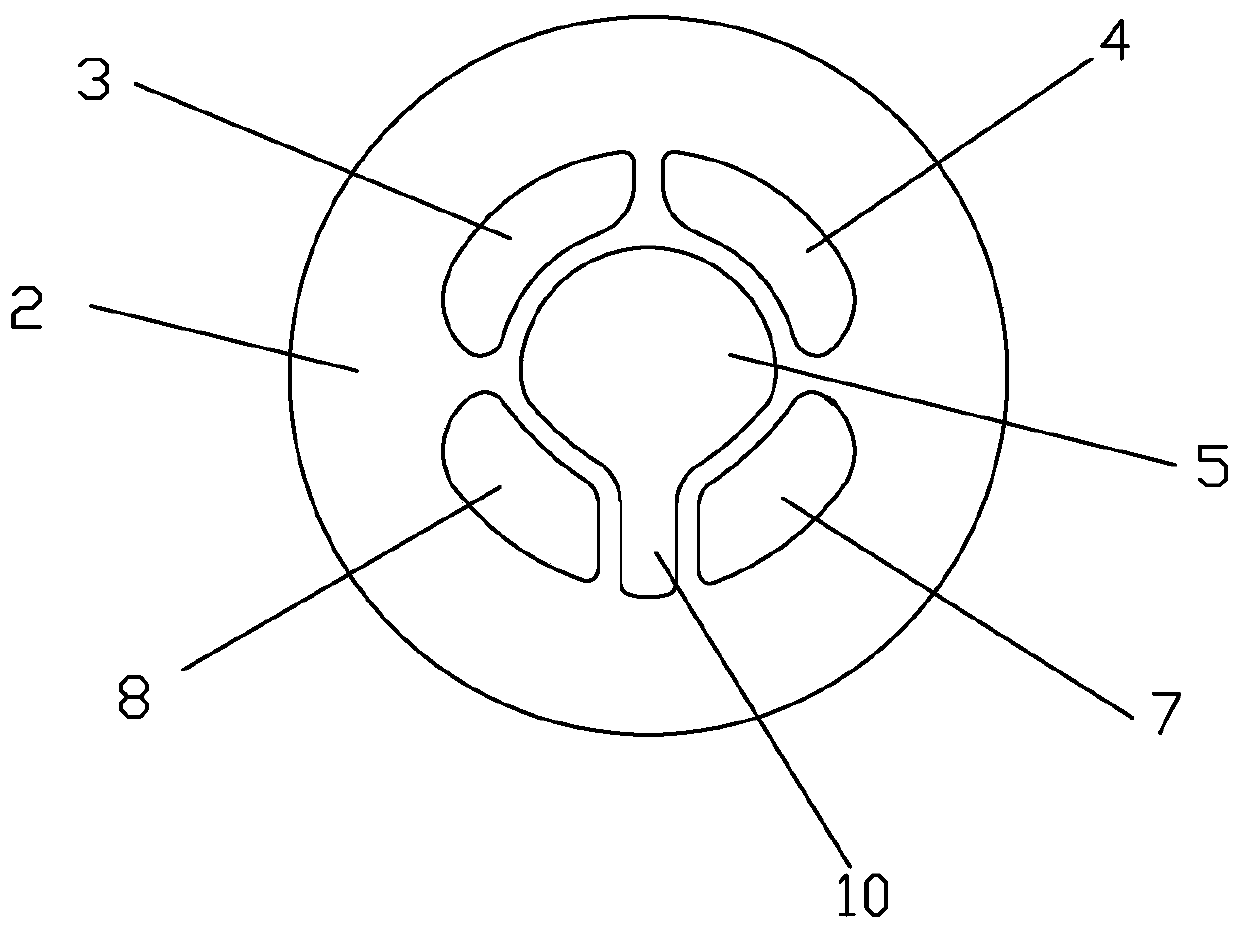

[0057] like image 3 and Figure 4 As shown, a valve plate assembly capable of precise temperature adjustment includes a movable valve plate 1 and a fixed valve plate 2 , and the upper surface of the fixed valve plate 2 is provided with a cold water inlet 3 , a hot water inlet 4 and a mixed water outlet 5 . The mixed water outlet 5 is located in the middle of the upper surface of the fixed valve plate 2, and the hot water inlet 4 and the cold water inlet 3 are respectively located on the upper right side and the upper left side of the mixed water outlet 5. The lower left side of the mixed water outlet 5 is provided with a cold water replenishment port 8 , and the lower right side of the mixed water outlet 5 is provided with a hot water replenishment port 7 . During use, the hot water inlet 4 and the hot water replenishment port 7 are all communicated with the hot water supply pipe, and t...

Embodiment 2

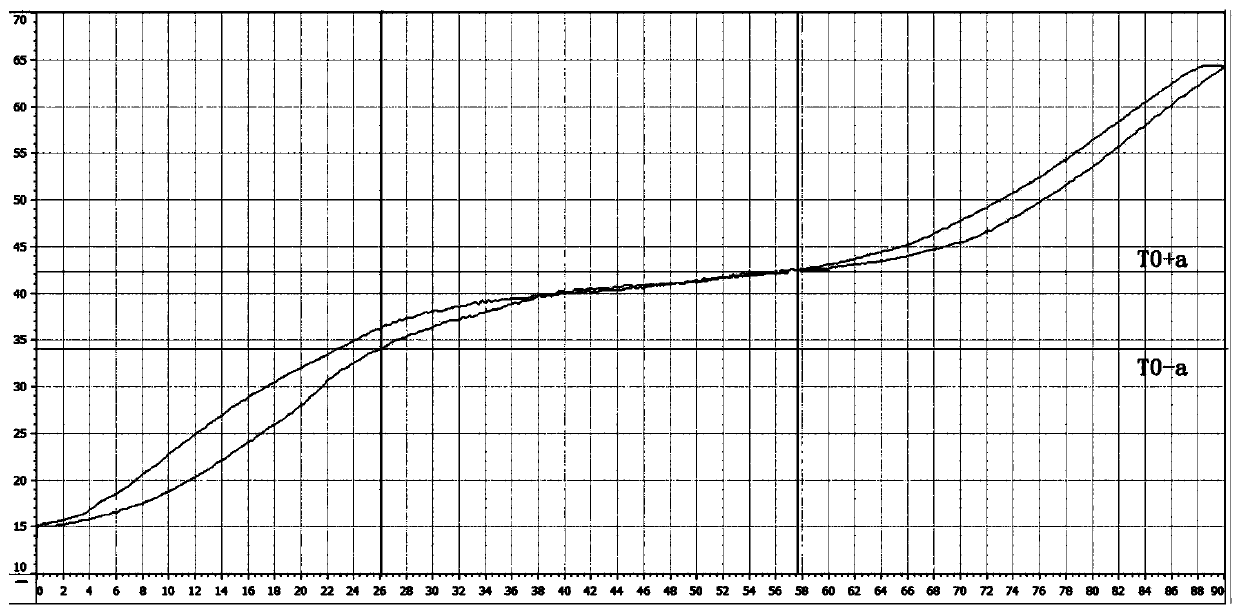

[0069] Embodiment 2, a valve assembly with precise temperature adjustment

[0070] like Figure 11 and Figure 12 As shown, a valve plate assembly capable of precise temperature adjustment, the upper surface of the fixed valve plate 2 is provided with a cold water inlet 3, a hot water inlet 4, a cold water replenishment port 8, a hot water replenishment port 7 and a mixed water outlet 5. Wherein the mixed water outlet 5 is positioned at the middle part of the fixed valve plate 2, the hot water inlet 4 is positioned at the upper right side of the mixed water outlet 5, and the cold water inlet 3 is positioned at the left upper side of the mixed water outlet 5. The hot water replenishment port 7 is located at the lower right side of the mixed water outlet 5 , and the cold water replenishment port 8 is located at the left lower side of the mixed water outlet 5 . The hot water inlet 4, the hot water replenishment port 7, the cold water inlet 3 and the cold water replenishment por...

Embodiment 3

[0076] Embodiment 3, a spool with precise temperature adjustment

[0077] like Figure 19 As shown, a valve core capable of precise temperature regulation includes the valve plate assembly in Embodiment 1 or Embodiment 2, and also includes a housing 13 , a base 14 , a control handle 15 , a rotating seat 17 and a chuck 16 . The swivel base 17 is rotatably installed on the upper end of the housing 13, and the control handle 15 is swingably installed in the swivel base 17. The control handle 15 and the swivel base 17 are connected by a rotating shaft 19, so that the control handle 15 two ends can swing. The chuck 16 , the movable valve plate 1 and the fixed valve plate 2 are installed in the housing 13 . The fixed valve plate 2 is fixed on the base 14 , and a sealing member 20 is installed between the fixed valve plate 2 and the base 14 . A seal 20 is also installed at the lower end of the base 14 . The base 14 is provided with a clamping block, and the clamping block is clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com