A spraying device for medium-sized bus motor castings

A technology of spraying equipment and castings, which is applied in spraying equipment, liquid spraying equipment, spray booths, etc., and can solve the problems of workers' physical damage, high requirements, uneven spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

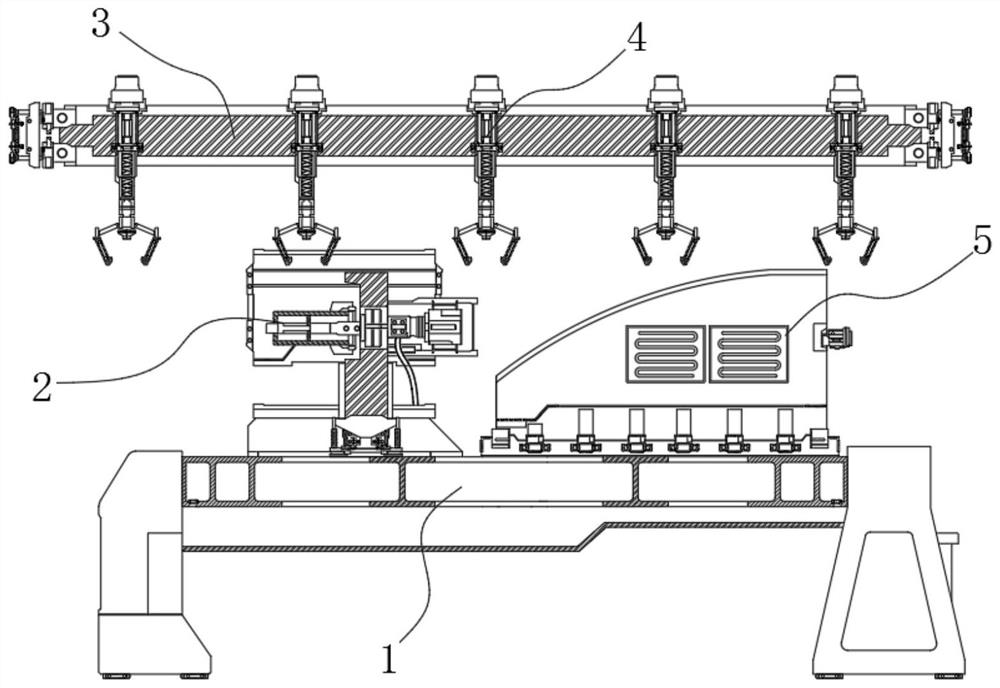

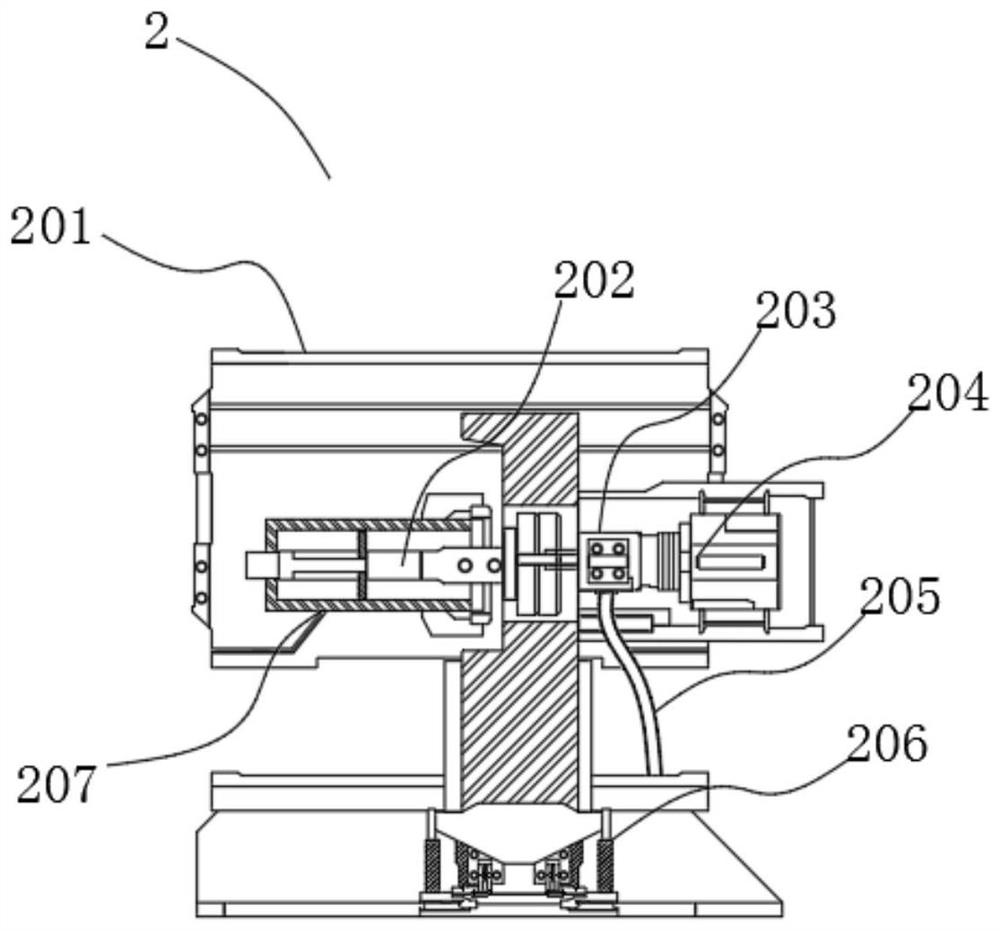

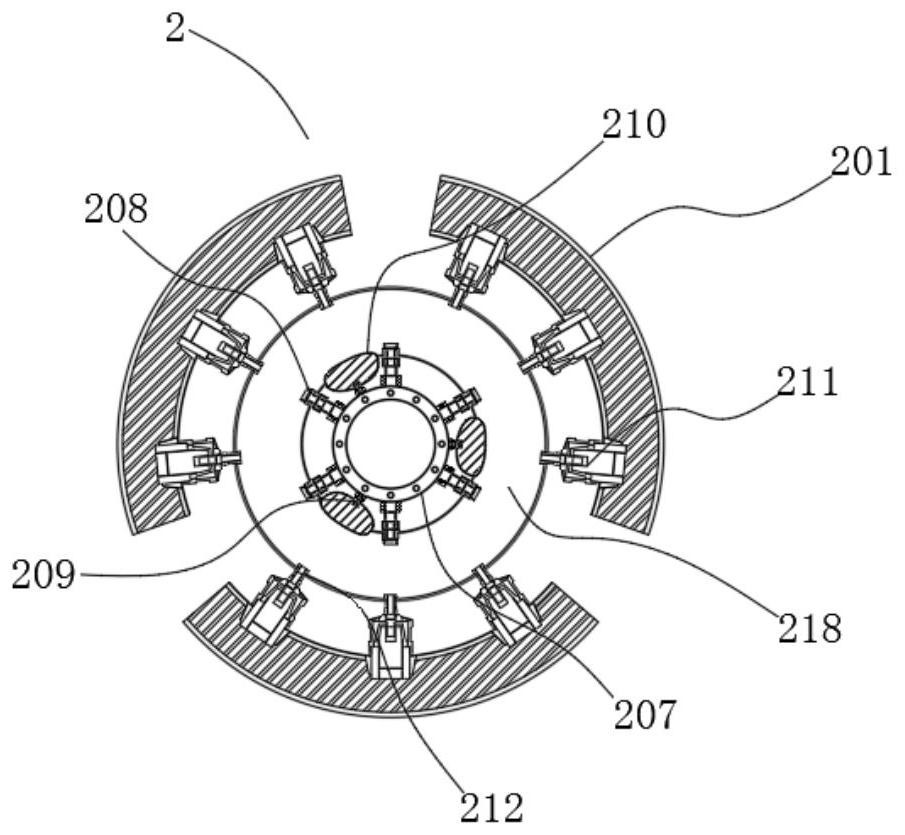

[0021] refer to figure 1 , the present invention provides a technical solution: a spraying device for medium-sized passenger car motor castings, which includes a support table 1, and a spraying assembly 2 is arranged on the support table 1, and the spraying assembly 2 is used for motor castings. The outer wall and the inner wall are sprayed in all directions. After the spraying operation, the motor casting is transferred to the drying device 5 by the transmission assembly 3 for drying treatment. The drying device 5 is arranged on the supporting workbench 1 On the right side of the upper end surface, the transmission assembly 3 is fixedly arranged directly above the supporting workbench 1, and multiple sets of clamping assemblies 4 are installed on the transmission assembly 3, leaving a certain space between each of the clamping assemblies 4 , so that the transmission assembly 3 moves at intervals when transferring the motor castings, thereby ensuring that each of the motor cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com