Laser code inkjet printing and meter counting synchronization device for plastic pipeline and control method

A plastic pipe and laser coding technology, applied in printing devices, measuring devices, printing, etc., can solve problems such as market development restrictions, synchronization difficulty in achieving consistency, and quality requirements cannot be guaranteed, so as to improve product quality and facilitate use , the effect of precision guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

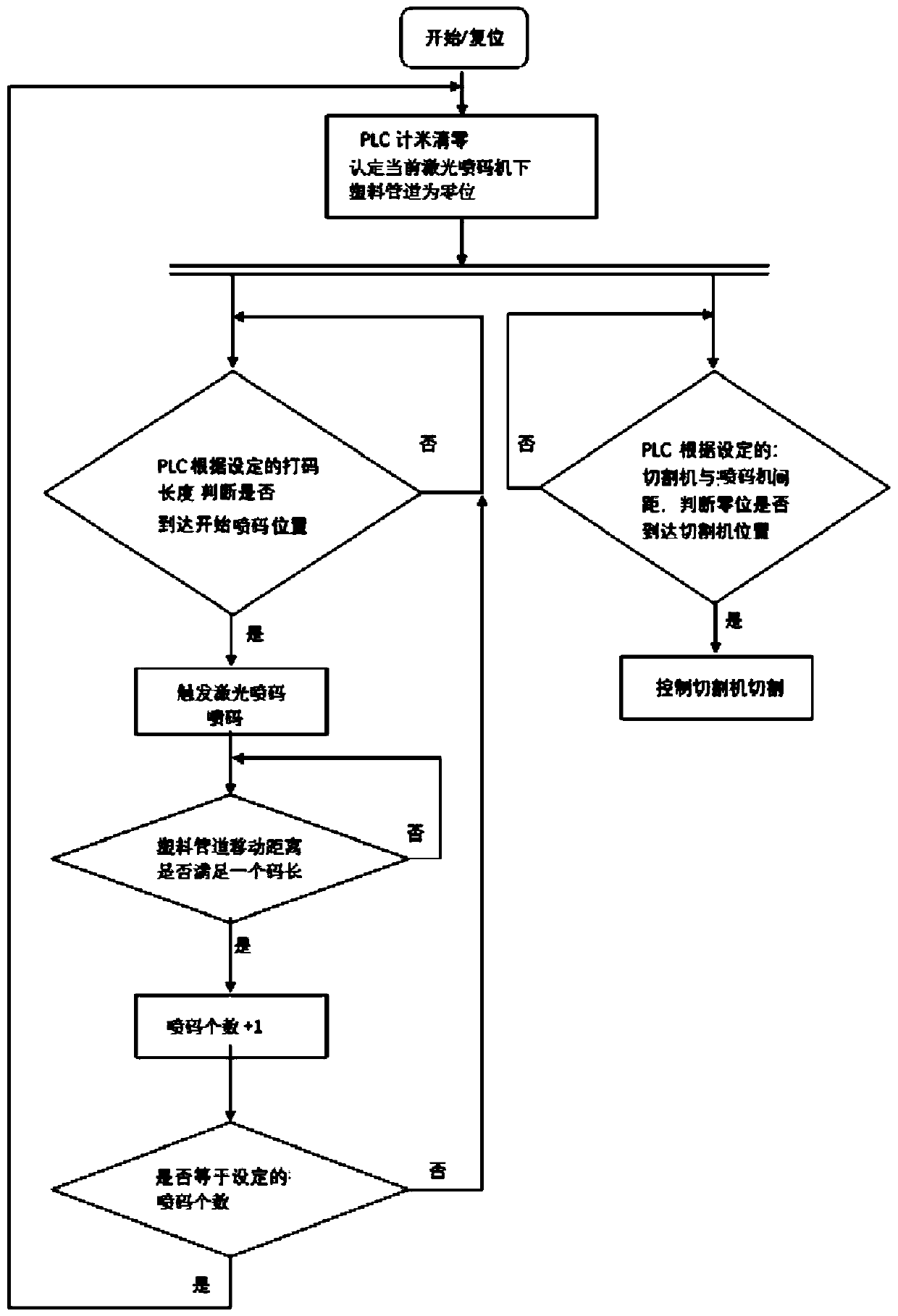

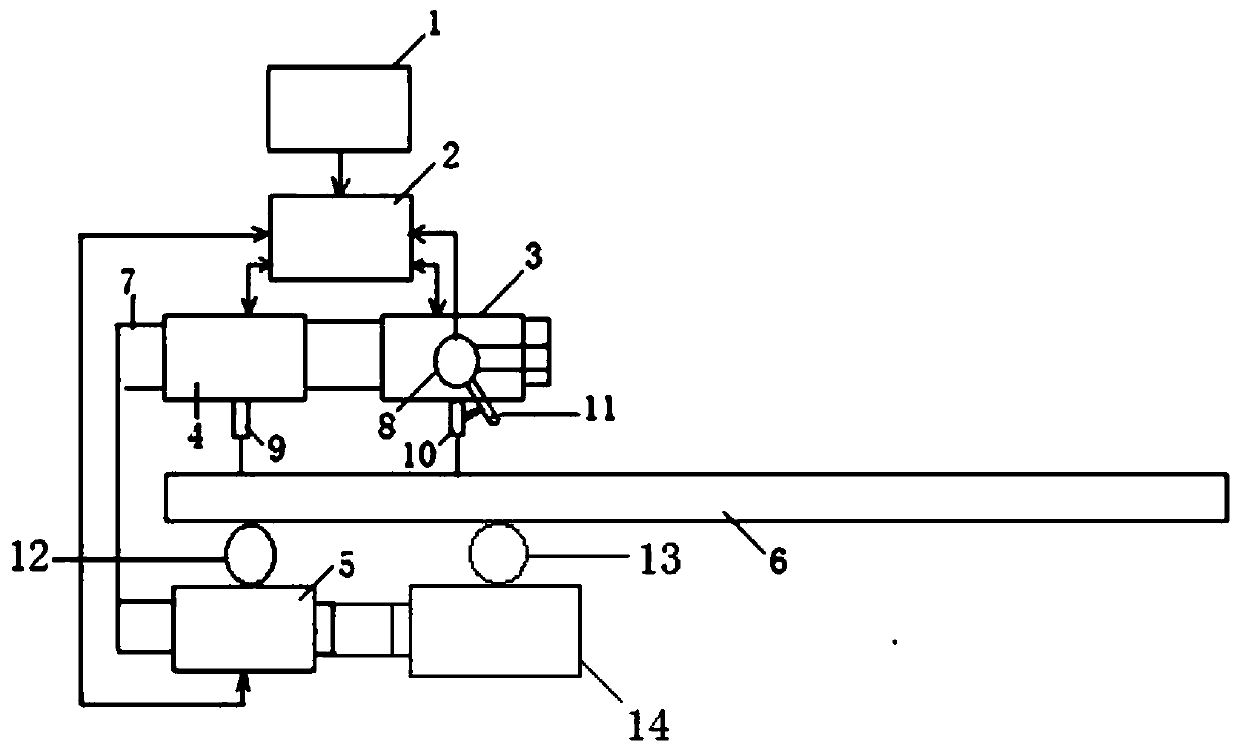

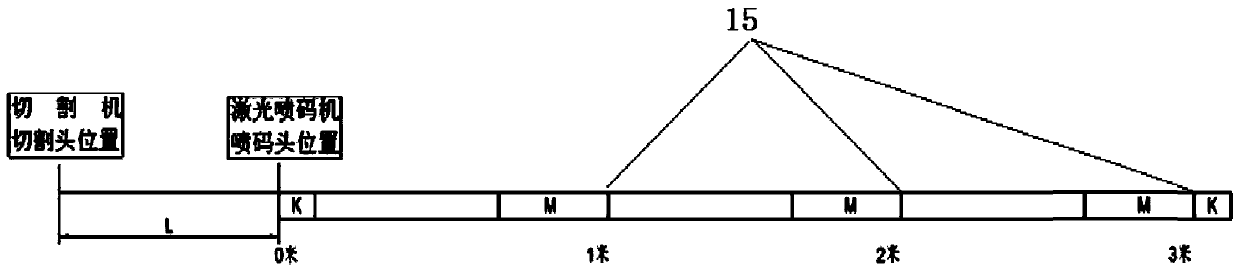

[0022] see Figure 1-3 , a synchronous device for laser coding and meter counting of plastic pipes according to the present invention, comprising: a cutting machine for cutting plastic pipes according to set specifications; Parameter setting; PLC system, used to control the laser inkjet printer and cutting machine to run synchronously according to the set parameters; laser inkjet printer, used to implement inkjet code on plastic pipes; meter encoder, used to detect plastic pipes Moving distance and meter counting bracket, used to support the operation display screen, PLC system, cutting machine, laser inkjet printer, meter counting encoder, and place the cutting head of the cutting machine and the jetting end of the laser inkjet printer on the area to be cut Above the plastic pipe; the operation display screen is respectively connecte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap