Article fixation apparatus and article fixation structure assembly method

A technology for fixing devices and articles, applied in the directions of transportation and packaging, additional accessories, vehicle parts, etc., can solve the problems of easy deformation, complicated sealing structure of closed gaps, etc., and achieve the effect of improving installation workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

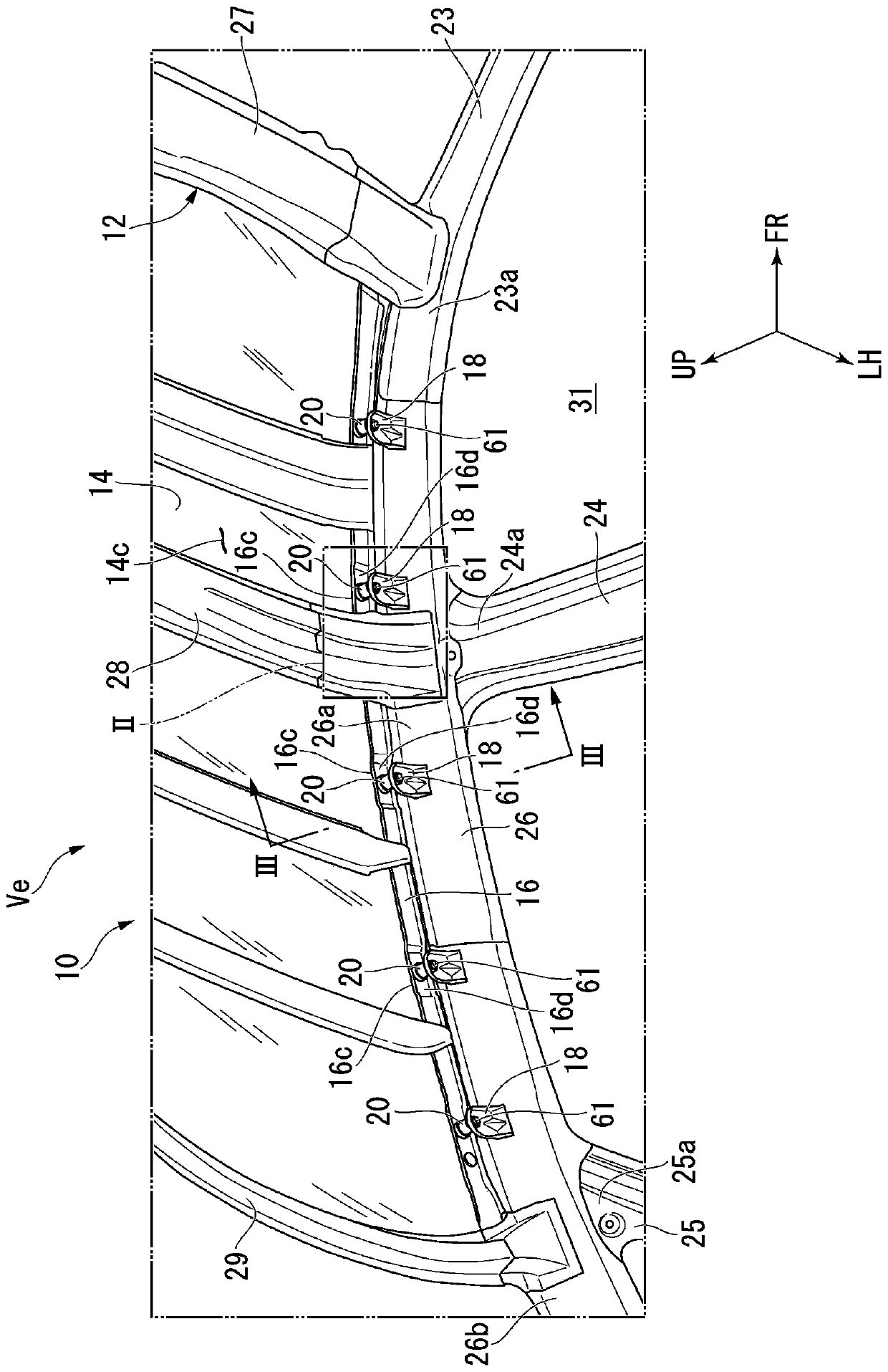

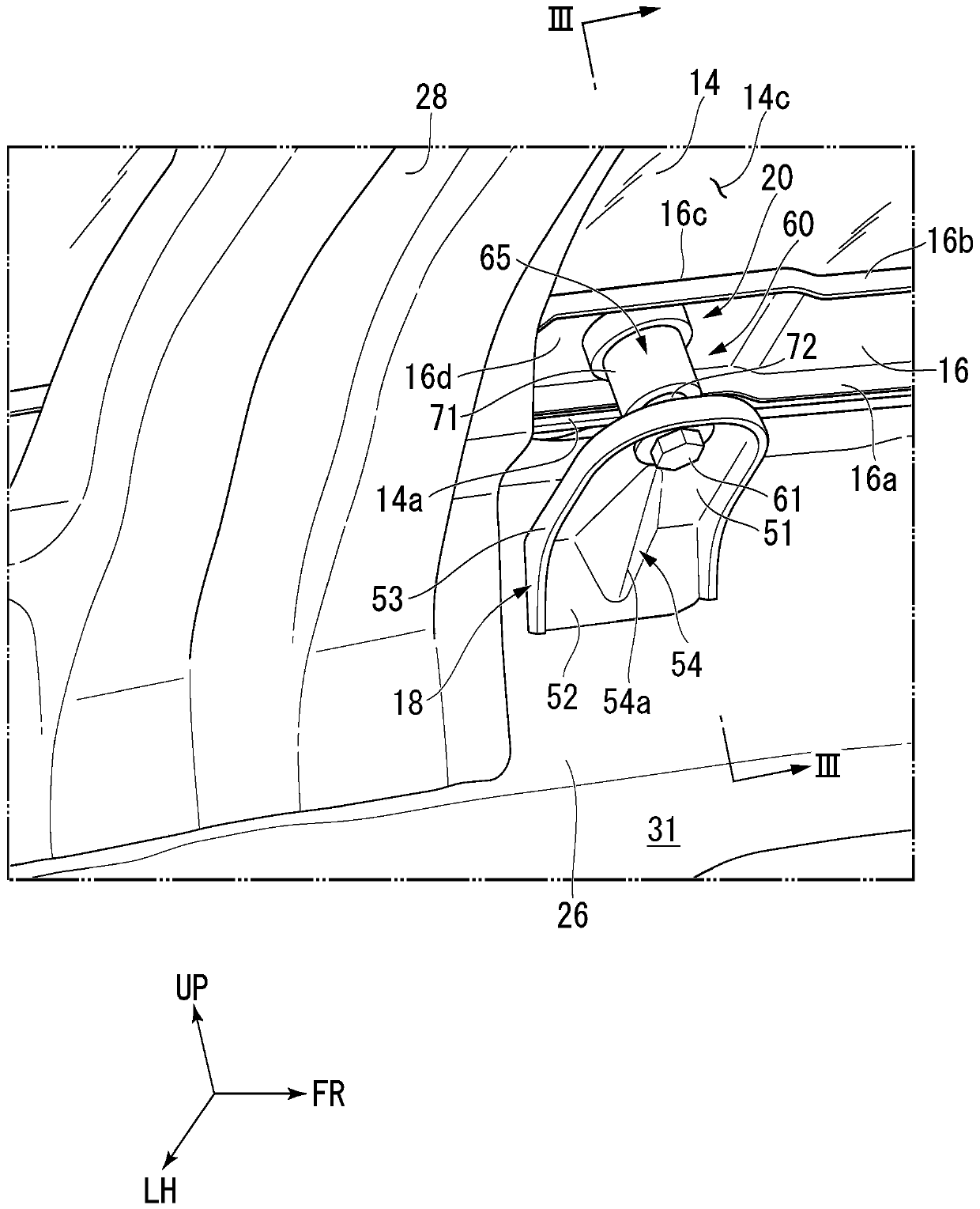

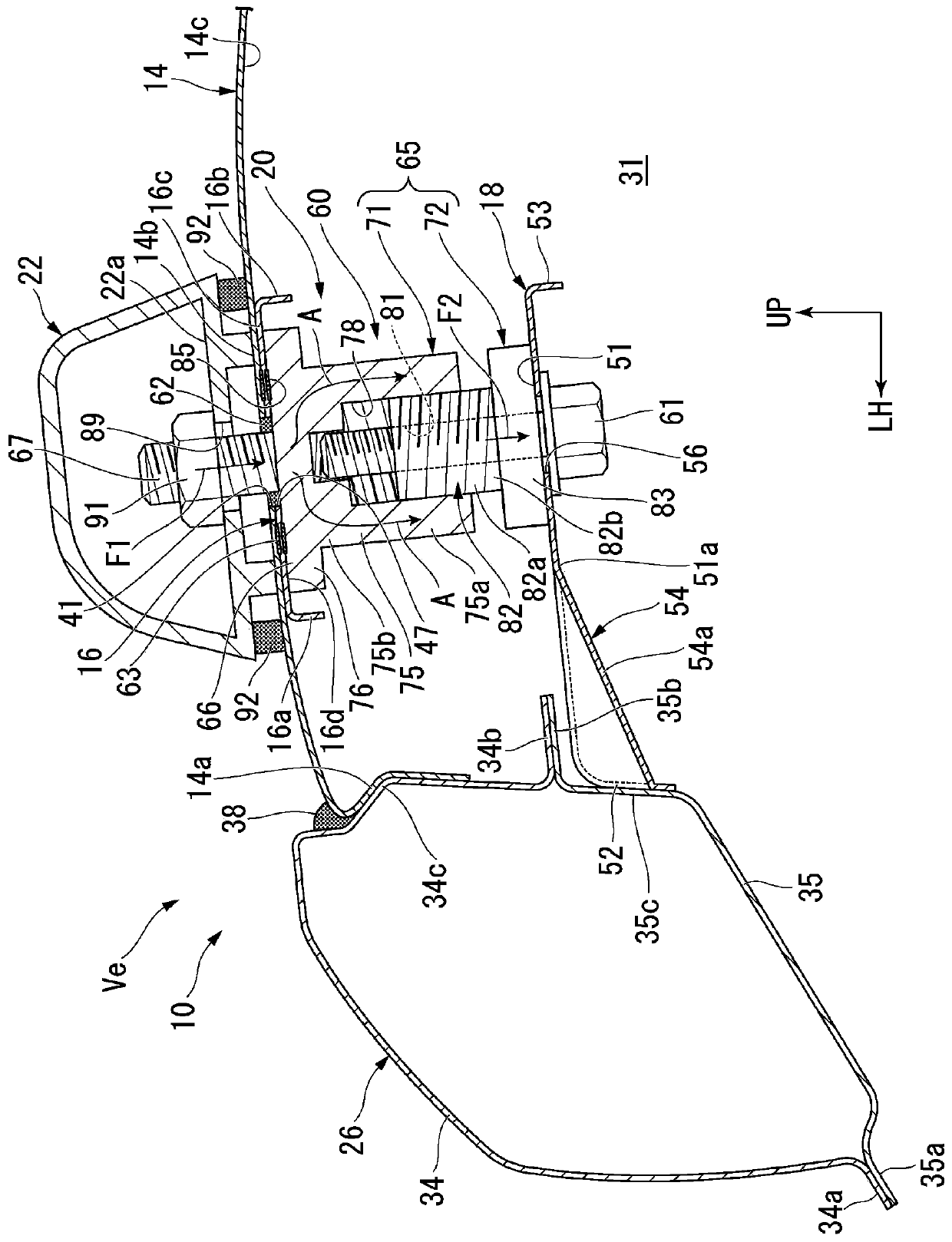

[0055] like figure 1 , figure 2 As shown, a vehicle body superstructure 10 has a body frame member 12, a roof (body panel, first panel) 14, a reinforcement member 16, a plurality of support members (second panel) 18, a plurality of article securing devices 20, and a roof rail ( Item) 22 (refer to image 3 ).

[0056] The vehicle body frame member 12 includes a front pillar 23 , a center pillar 24 , a rear pillar 25 , a roof rail 26 , a front roof cross member 27 , a center roof cross member 28 , and a rear roof cross member 29 .

[0057] The front pillar 23 is erected on the front left side of the cabin 31 and is formed in a closed cross section. The front roof cross member 27 is spanned over the upper end portion 23a of the left front pillar 23 and the upper end portion (not shown) of the right front pillar along the vehicle width direction.

[0058] The center pillar 24 is erected on the left side of the center of the cabin 31 and has a closed cross section. The rear p...

no. 2 approach

[0109] like Figure 5 As shown, the vehicle body upper structure 100 includes a support member 102 instead of the support member 18 of the first embodiment, and the other structures are the same as those of the vehicle body upper structure 10 of the first embodiment.

[0110] The support member 102 is a cross member that is mounted on the left roof rail (left frame) 26 and the right roof rail (right frame) (not shown) and extends in the vehicle width direction along the roof panel 14 .

[0111] Examples of the supporting member 102 include a roof arch that reinforces the roof panel 14 and the like, a sunroof frame member that opens and closes the roof, and the like.

[0112] The support member 102 has a support mounting portion 104 at the left end. The support attachment part 104 is provided at intervals below the raised part 16c of the reinforcement member 16 similarly to the support attachment part 51 of 1st Embodiment. The adjustment mechanism 65 is interposed between the...

no. 3 approach

[0116] like Figure 6 ~ Figure 8 As shown, the vehicle body upper structure 110 is provided with a reinforcing member 112 and a roof rail mounting member 113 (item mounting member) instead of the reinforcing member 16 and the roof rail mounting member 60 of the first embodiment, and other structures are the same as those of the vehicle body of the first embodiment. The superstructure 10 is the same.

[0117] The reinforcement member 112 has a roof rail 22 (refer to image 3 ) a plurality of first mounting and fixing portions 115 fixed and a plurality of second mounting and fixing portions 116 for fixing the adjustment mechanism 122 of the roof rail mounting member 113 .

[0118] The first mounting and fixing portion 115 is arranged in a state of being in contact with the lower surface 14 c of the top plate 14 . The fixed portion 121 of the roof rail mounting member 113 is fixed to the first mounting and fixing portion 115 . The second mounting and fixing portion 116 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com