Bidirectional floating fixing structure for carbon fiber composite material brake disc

A composite material and fixed structure technology, applied in the automotive field, can solve the problems of complex manufacturing process, affecting the use effect and service life of carbon fiber composite brake discs, and large installation space constraints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

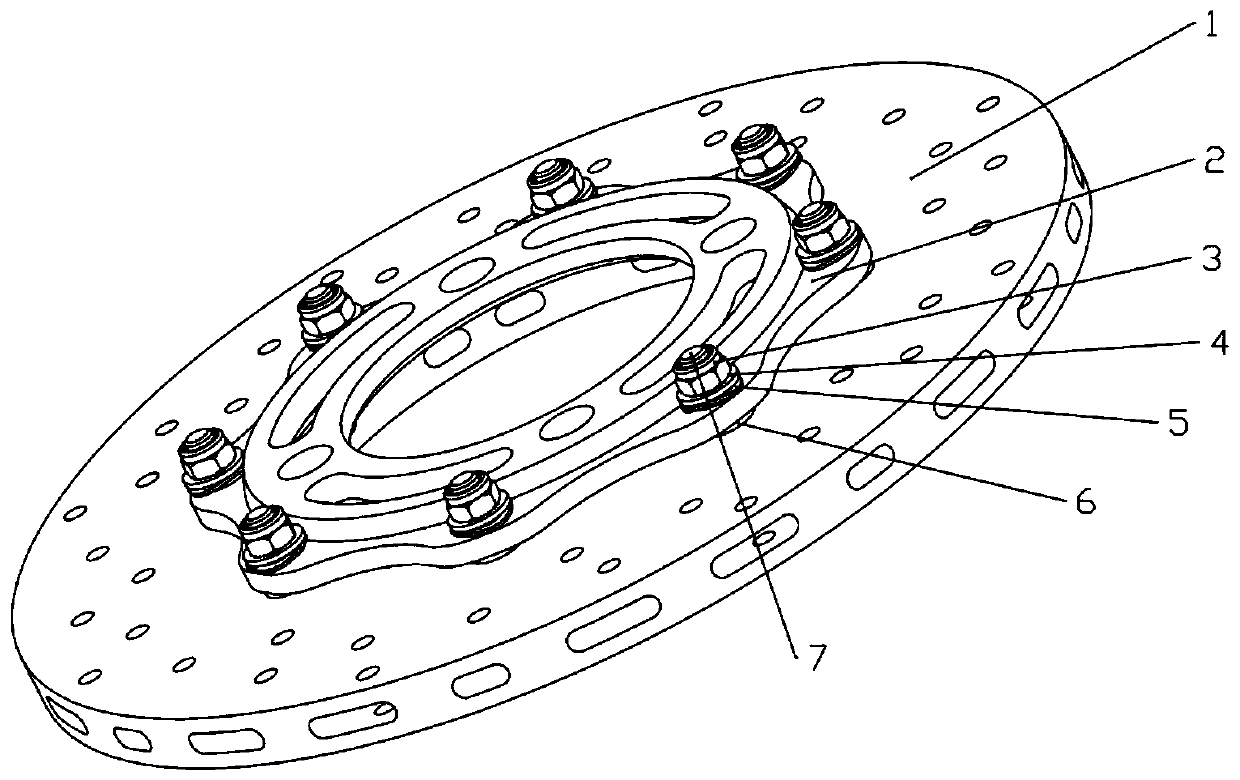

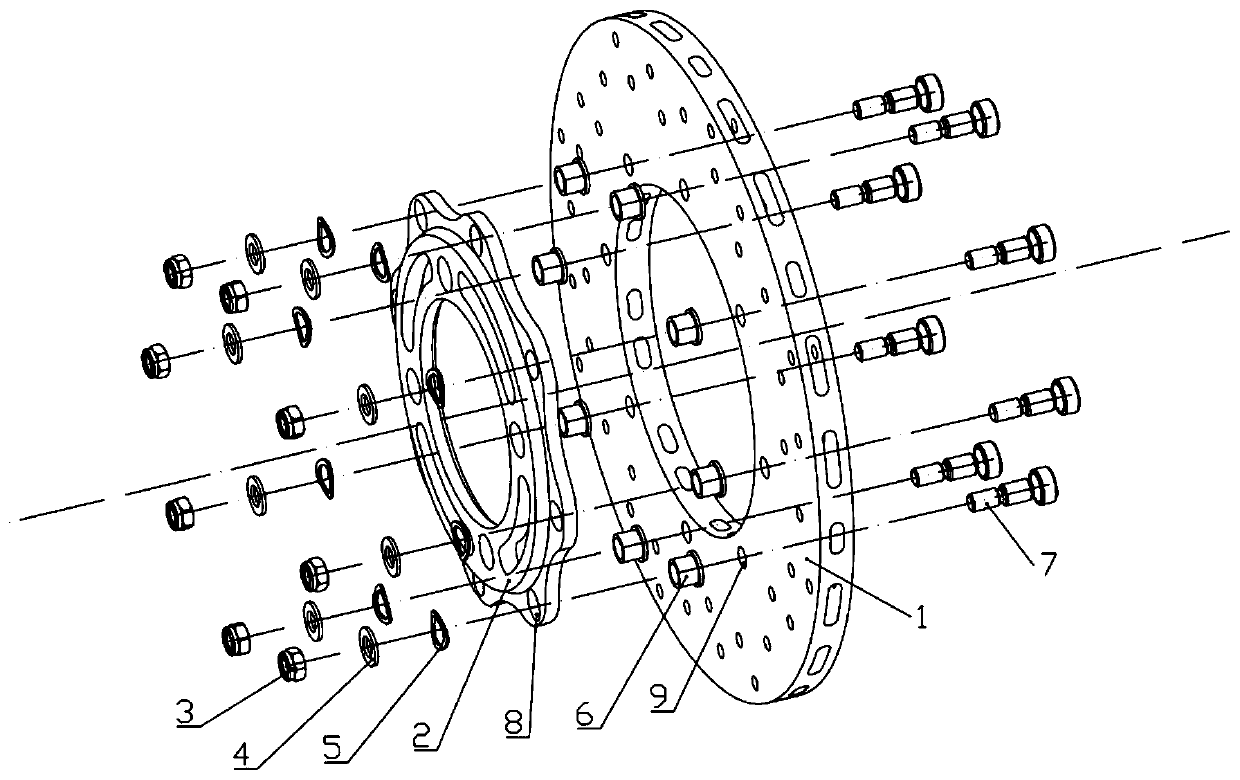

[0024] refer to figure 1 , figure 2 and image 3 , a two-way floating and fixed structure for a carbon fiber composite brake disc, the structure includes a carbon fiber composite brake disc 1, a metal adapter disc 2, a metal locknut 3, a metal gasket 4, a wave gasket 5, Metal bushing 6 and hinged hole bolt 7.

[0025] The composite material brake disc 1 is connected to the wheel hub through a metal transfer disc 2 ; the composite material brake disc 1 and the metal transfer disc 2 are connected to a metal locknut 3 through hinged hole bolts 7 .

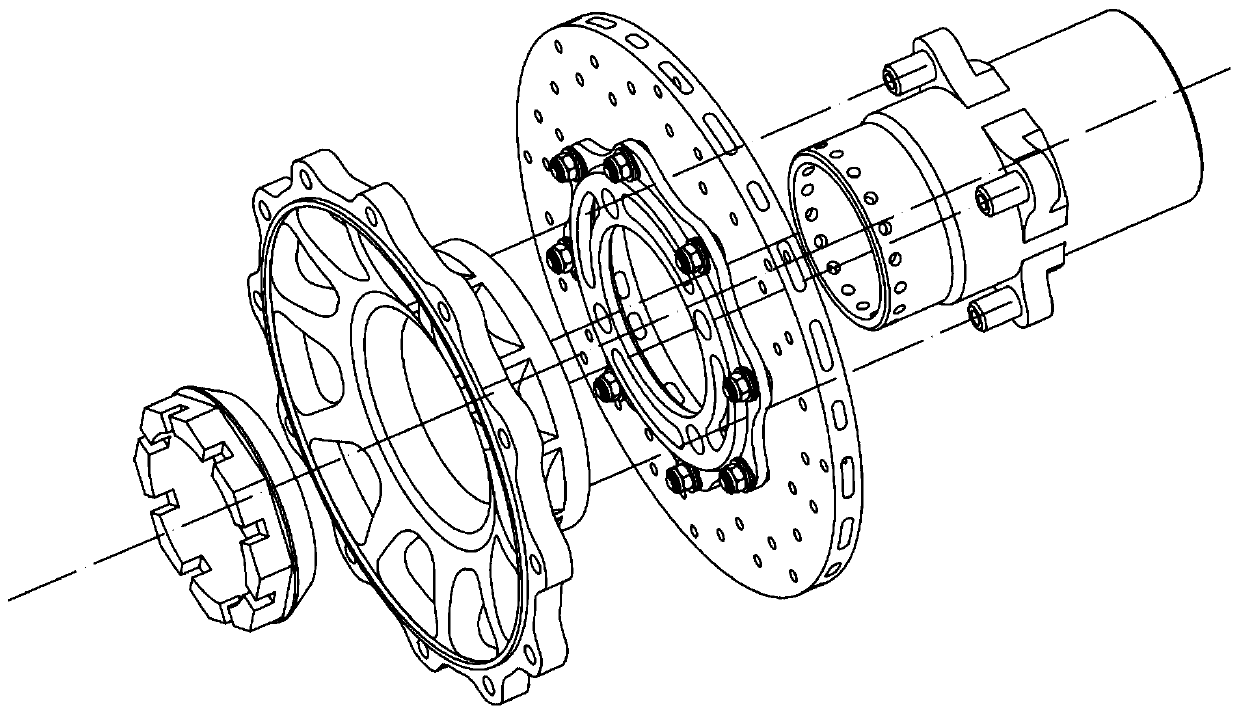

[0026] refer to Figure 4 , this structure is to avoid structural damage caused by the counterbore 9 on the carbon fiber composite brake disc fixing the reaming hole bolt 7 due to excessive shear load during the braking process, when connecting the carbon fiber The metal bushing 6 is assembled on the reaming hole bolt 7 of the composite material brake disc 1 and the metal adapter disc 2 .

[0027] refer to Figure 7 , the carbo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap