Memory metal pin pusher

A technology of memory metal and pusher, which is applied in the direction of aircraft, spaceflight vehicle, spaceflight vehicle guide device, etc. It can solve the problems of not being suitable for controllable drive, complex structure, large volume, etc., so as to avoid unsmooth sliding and push The effect of smooth process and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

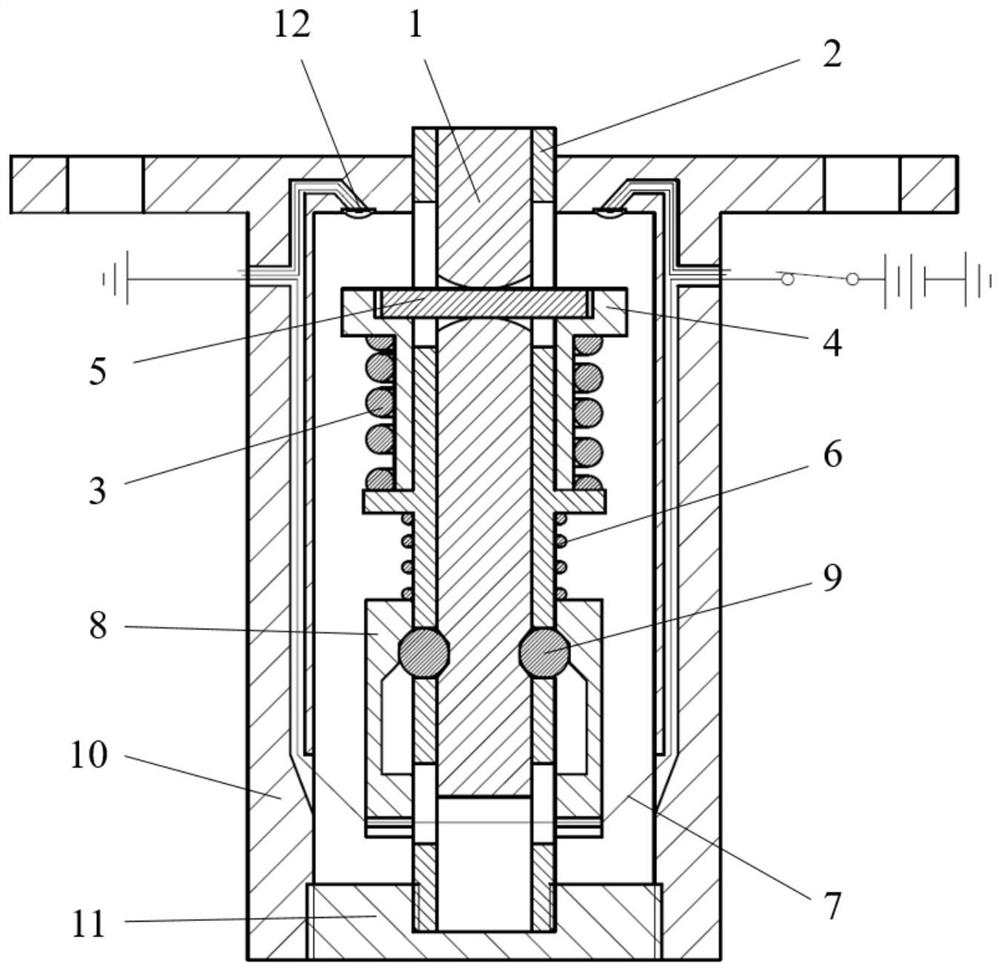

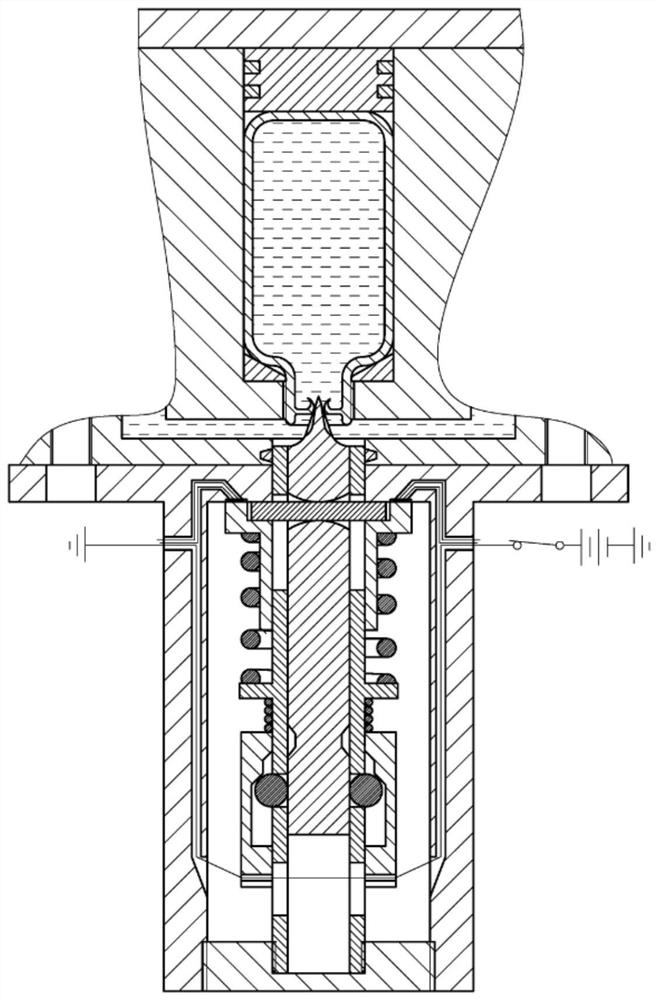

[0027] The invention provides a kind of memory metal pusher, its structure is as follows figure 1 As shown, it includes sliding pin 1, cage 2, driving spring 3, spring bushing 4, driving pin 5, return spring 6, SMA wire 7, sliding sleeve 8, ball 9, housing 10, bottom cover 11 and position sensor 12.

[0028] The sliding pin 1 and the functional parts installed on the top of the sliding pin 1 constitute the functional unit of the pusher. Among them, the sliding pin 1 is a shaft-shaped structure, which can slide up and down in the inner cavity of the tubular cage 2; the lower part of the sliding pin 1 is provided with a trapezoidal groove, which is used to cooperate with the ball 9 in the initial stable state; the middle part of the sliding pin 1 is provided with The dumbbell-shaped transverse through hole is used to install the transmission pin 5; the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap