Memory metal pin puller with high shear resistance

A technology of memory metal and pin puller, which is applied in the docking device of aerospace vehicles, etc., can solve the problems of uneven spring pressing force, lack of real-time monitoring and control of the unlocking process, and no status output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

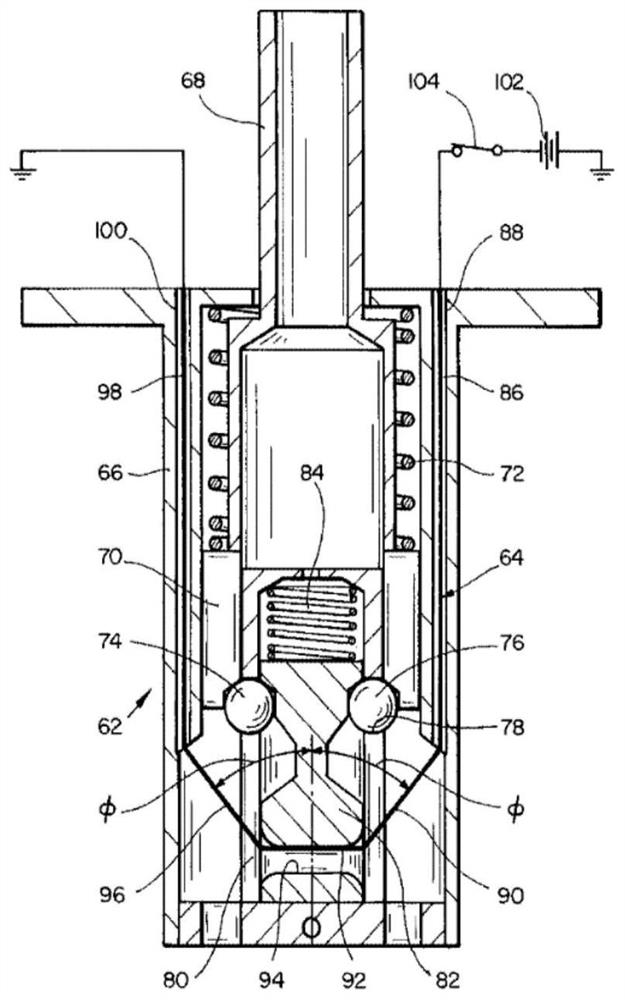

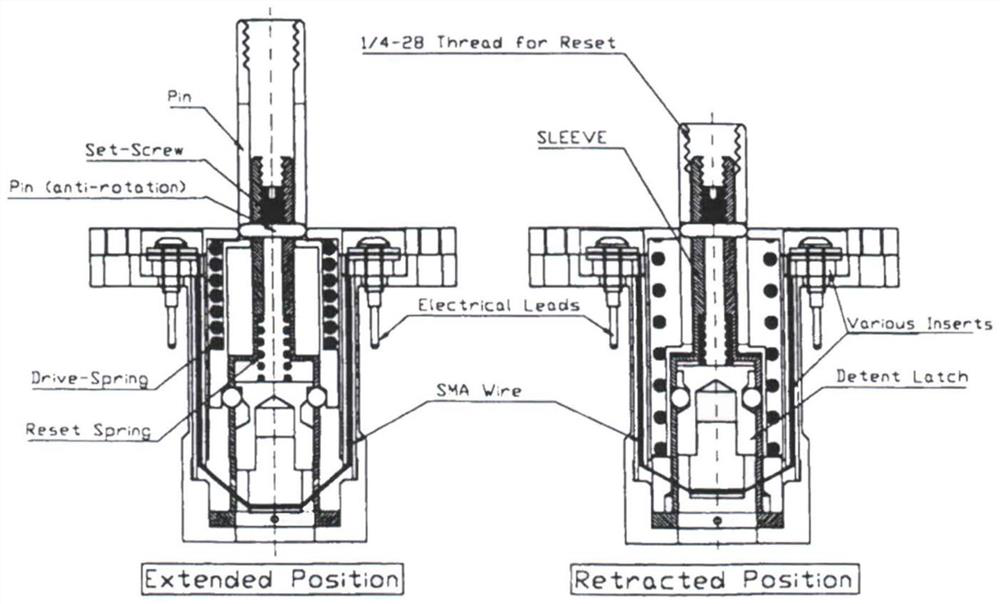

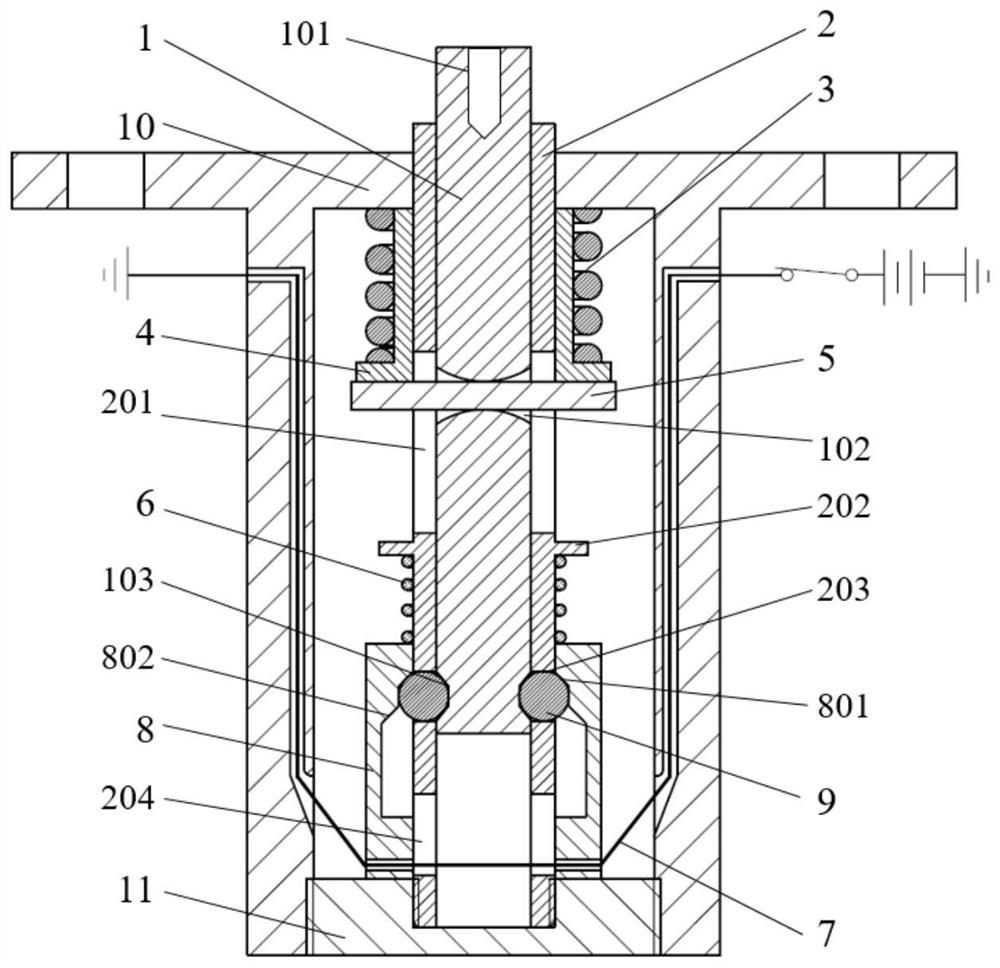

[0036] The invention provides a memory metal pin puller with high shear resistance, the structure of which is as follows: Figure 3 ~ Figure 5 As shown, it mainly includes an actuating element, a support unit, a trigger unit, a drive unit and a control unit.

[0037] Among them, the sliding pin 1 is an actuating element that provides locking and unlocking functions to the outside. When working, the pin puller is fixed on the connection structure. When the sliding pin 1 is extended, it can bear the shear load from the separation structure and limit the separation. The movement of the structure, when the sliding pin 1 is in a contracted state, releases the limit to the separation structure.

[0038] The support unit is composed of a cage 2, a housing 10 and a bottom cover 11, which provide support and positioning for other parts of the pin puller; the cage...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap