Crank arm swing conveying device and method thereof

A technology of crank arm and conveyor line, which is applied in the field of crank arm swing conveyor, which can solve the problems of poor load capacity, low turning height, and limited size of the outer packaging of the conveyed goods, so as to improve the utilization rate of vertical space and simplify the layout Spatial structure, the effect of improving the accuracy of layer-changing docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

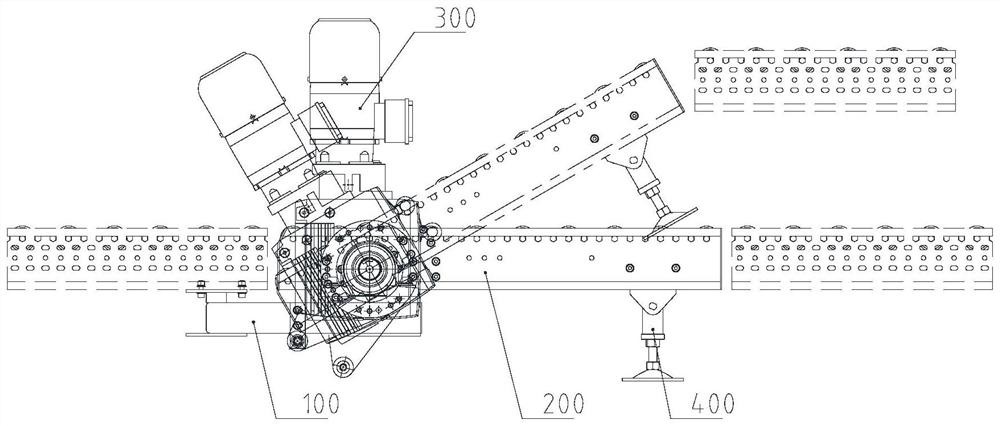

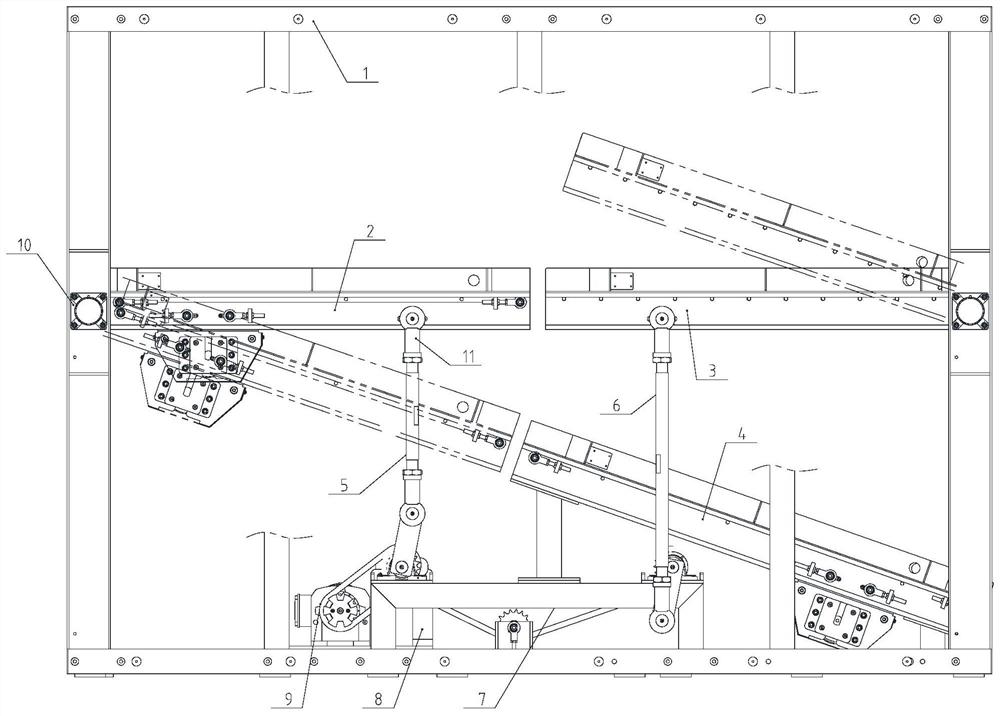

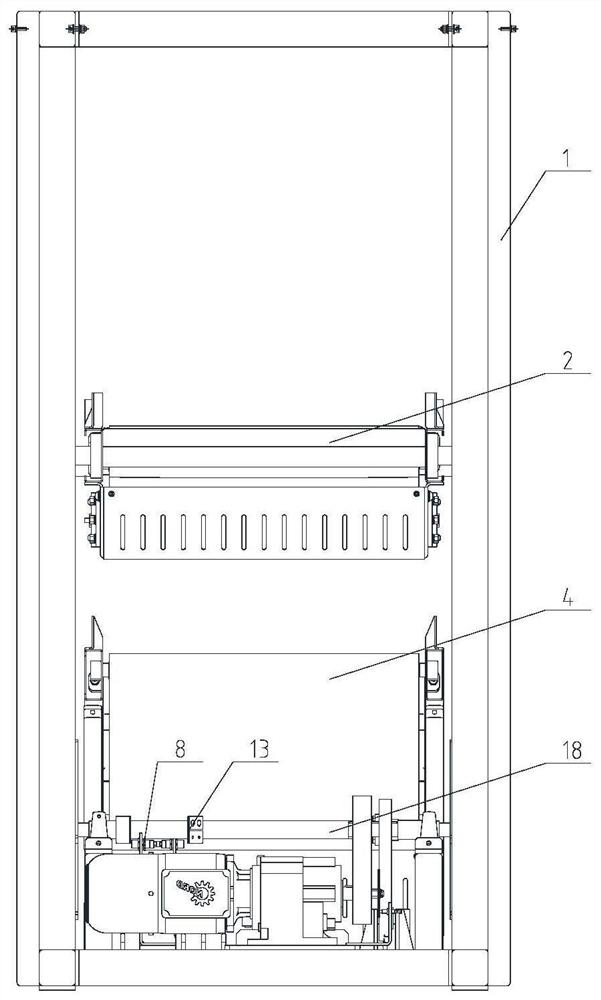

[0036] Embodiment 1, the curved arm swing conveying device described in this application, in order to improve the simplicity and flexibility of the overall scheme layout of the conveying system, a layer-changing structure and pendulum when the single-layer line body and the double-layer line body are docked are designed. The layer-changing method improves the operation efficiency of layer-changing transportation and the stability of transmission parts as a whole, and ensures the rate and accuracy of layer-changing angle and height.

[0037] For this reason, this application adopts a multi-stage conveying line structure, and two sets of curved arm assemblies driven by a geared motor realize layer-changing reciprocating swing between two layers of conveying lines.

[0038] Specifically, the crank arm swing conveying device includes a frame 1, and a single-layer swing conveying line, a double-layer swing conveying line and a double-layer fixed conveying line installed on the frame...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap