Elevator steel wire rope anomaly detection method, device and equipment and readable storage medium

An anomaly detection and wire rope technology, applied in the field of equipment, readable storage media, devices, and elevator wire rope anomaly detection methods, can solve problems such as elevator safety hazards, lack of real-time performance, and difficulty in effectively grasping elevator wire ropes from time to time. The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

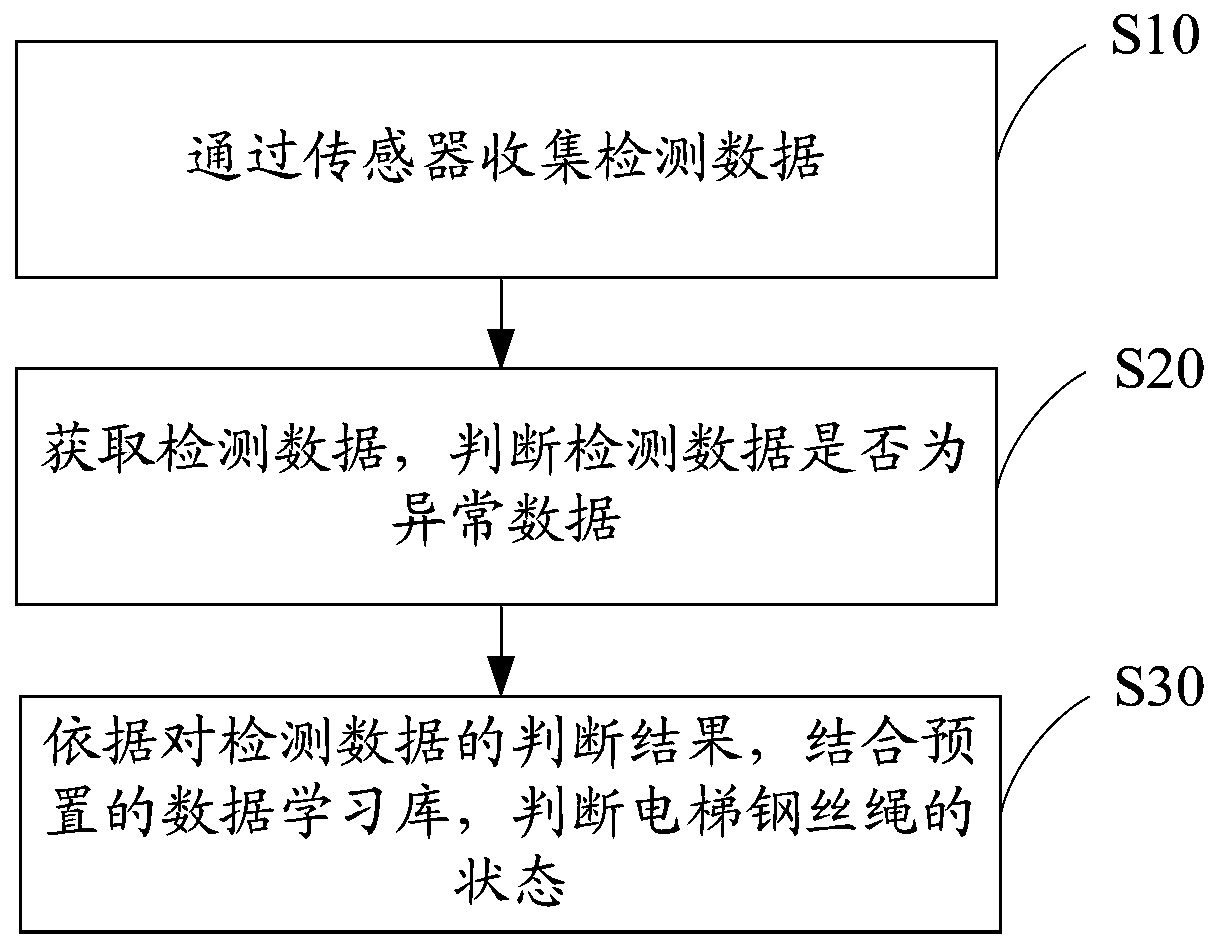

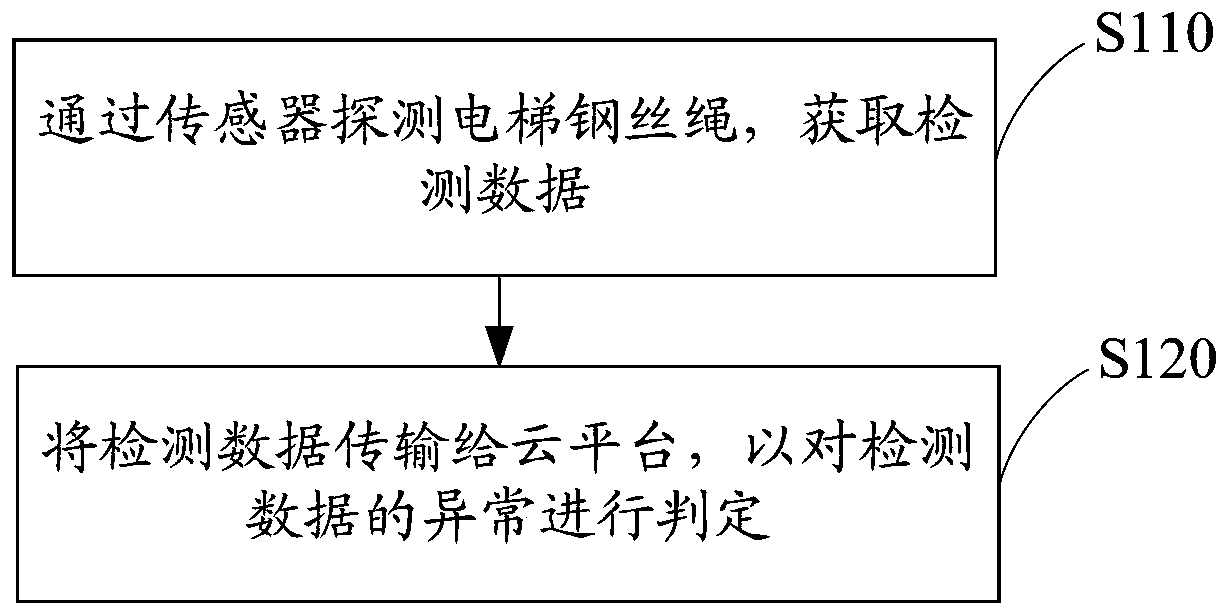

[0051] refer to figure 1As shown, the first embodiment of the present invention is a method for abnormality detection of elevator steel wire ropes. A sensor is arranged near the steel wire ropes. The method includes:

[0052] Step S10, collecting detection data through sensors;

[0053] Specifically, in the process of moving the elevator by the elevator wire rope, the wire rope will wear to different degrees. For example, if the thickness of the wire rope changes, the vibration of the wire rope may change. The detection data of the wire rope can be effectively measured by the vibration sensor. In addition, protruding points are set at certain distances on the steel wire rope, and the change of the protruding points of the steel wire rope can also be photographed and recorded by the photoelectric sensor, so as to detect whether the steel wire rope is broken.

[0054] Step S20, acquiring detection data, and judging whether the detection data is abnormal data;

[0055] Specific...

no. 4 example

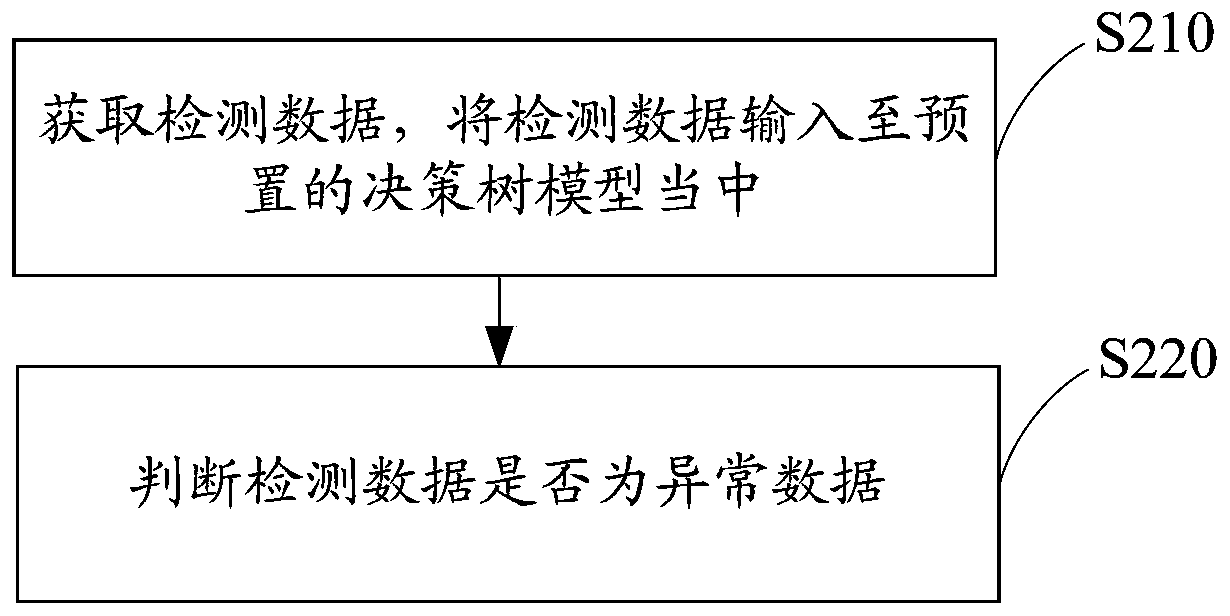

[0074] refer to Figure 4 As shown, on the basis of the third embodiment of the present invention, a fourth embodiment of the present invention is proposed. The sensor includes a first photoelectric sensor, a second photoelectric sensor, a third photoelectric sensor and a shock sensor to obtain detection data , the step S210 of inputting the detection data into the preset decision tree model includes:

[0075] Step S211, acquiring detection data, converting the detection data into corresponding numerical expressions, wherein 0 represents no detected signal, and 1 represents detected signal;

[0076] Specifically, the change of the protruding point of the steel wire rope is calculated by the first photoelectric sensor, the second photoelectric sensor and the third photoelectric sensor, and the vibration sensor is set close to the steel wire rope, so that the vibration data of the steel wire rope can be effectively measured. For example, in When the sensor detects the steel wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com