An adaptive variable mesh gap gear transmission method

A technology of variable meshing clearance and gear transmission, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of reducing gear life and transmission accuracy, system impact, affecting equipment reliability, etc., to reduce vibration and noise. , Improve system life and improve the effect of working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0040] Figure 4 It is an assembly drawing of a first-stage gearbox with a flexible high-damping adjustable clearance structure. Its external structure mainly includes cover plates, boxes, large end covers, small end covers and shafts and other main components.

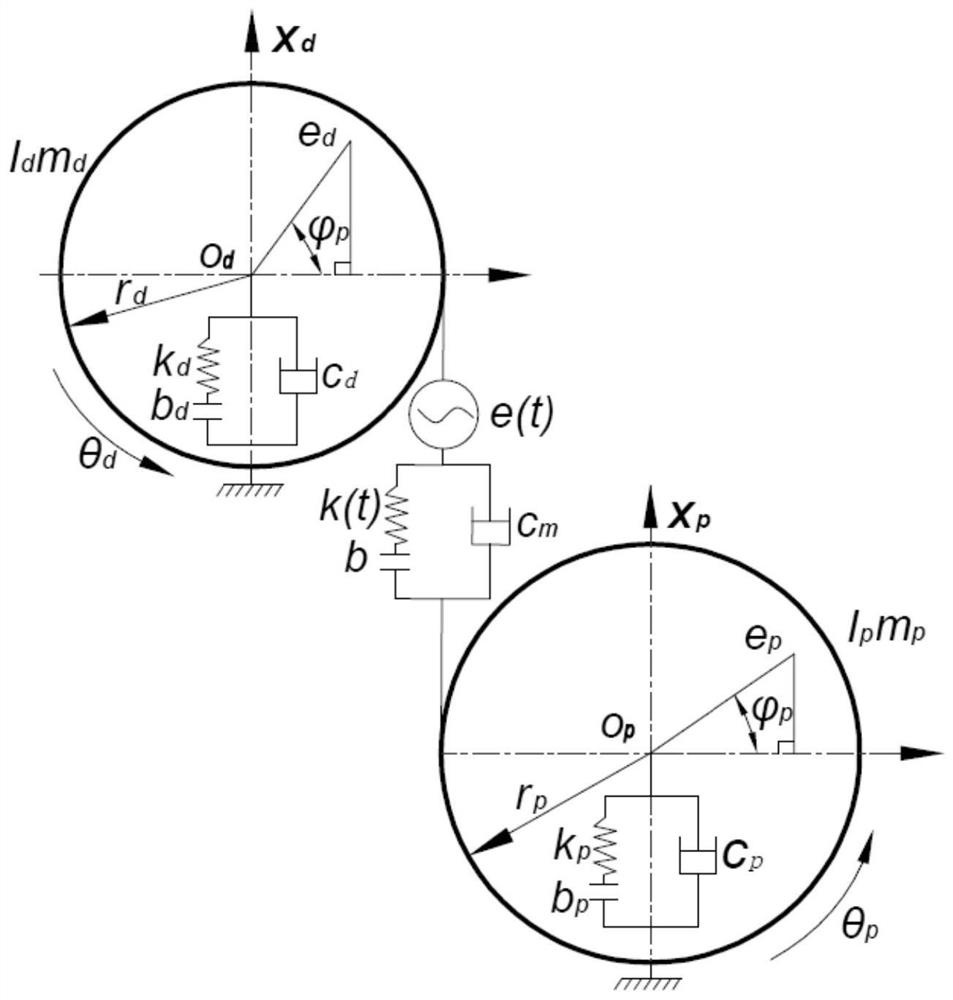

[0041] Figure 5 The exploded view of the gearbox is mainly composed of three parts: the driving gear-shaft system, the driven gear-shaft system and the box assembly. Among them, the driving gear-shaft system includes small end cover 2, variable clearance damping ring 4, push cylinder 5, driving bearing 7, driving gear 10, and driving shaft 11; the driven gear-shaft system includes large end cover 1, driven bearing 6, driven shaft 8 and driven gear 9. The box body assembly comprises box body 3, upper case cover 12, observation cover 13 and gasket 14.

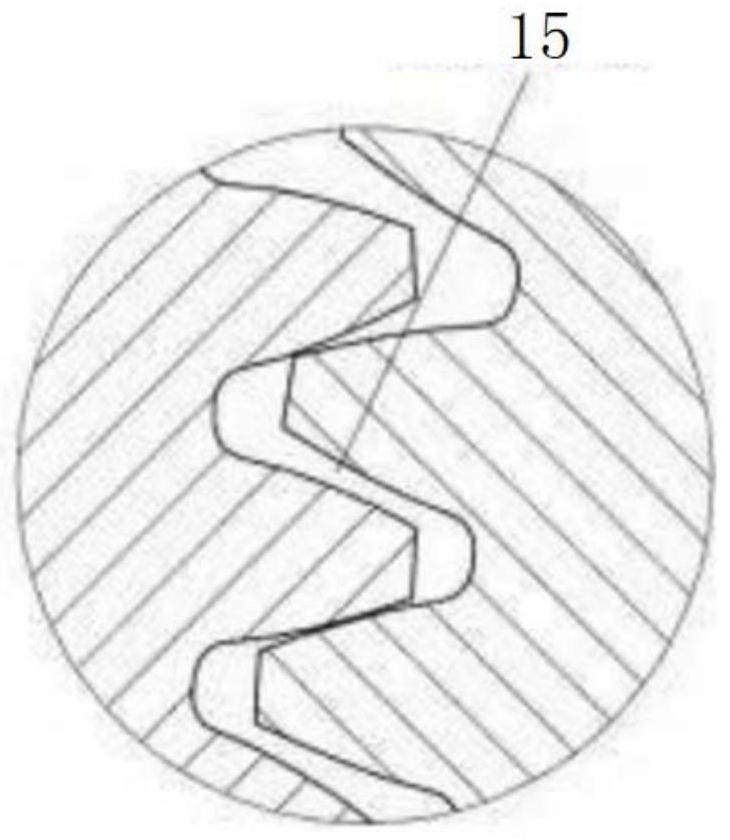

[0042] Due to the high input speed of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com