Crevice corrosion experiment device and method capable of regulating and controlling size of crevice in situ in real time

A real-time control, crevice corrosion technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem that the development of crevice corrosion cannot be truly reflected in real time, the width and coverage area of the crevice are fixed, and it is inconvenient to observe. Electrode surface corrosion development and other issues, to achieve the effect of accurate and reliable experimental results, scientific and rigorous experimental process, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

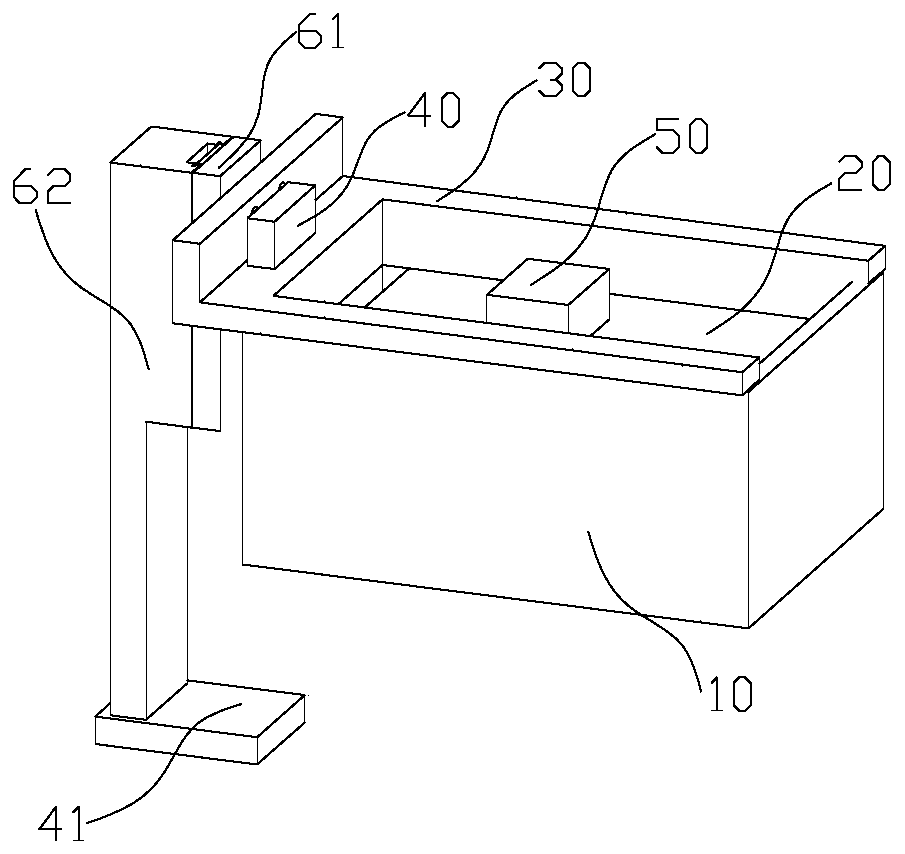

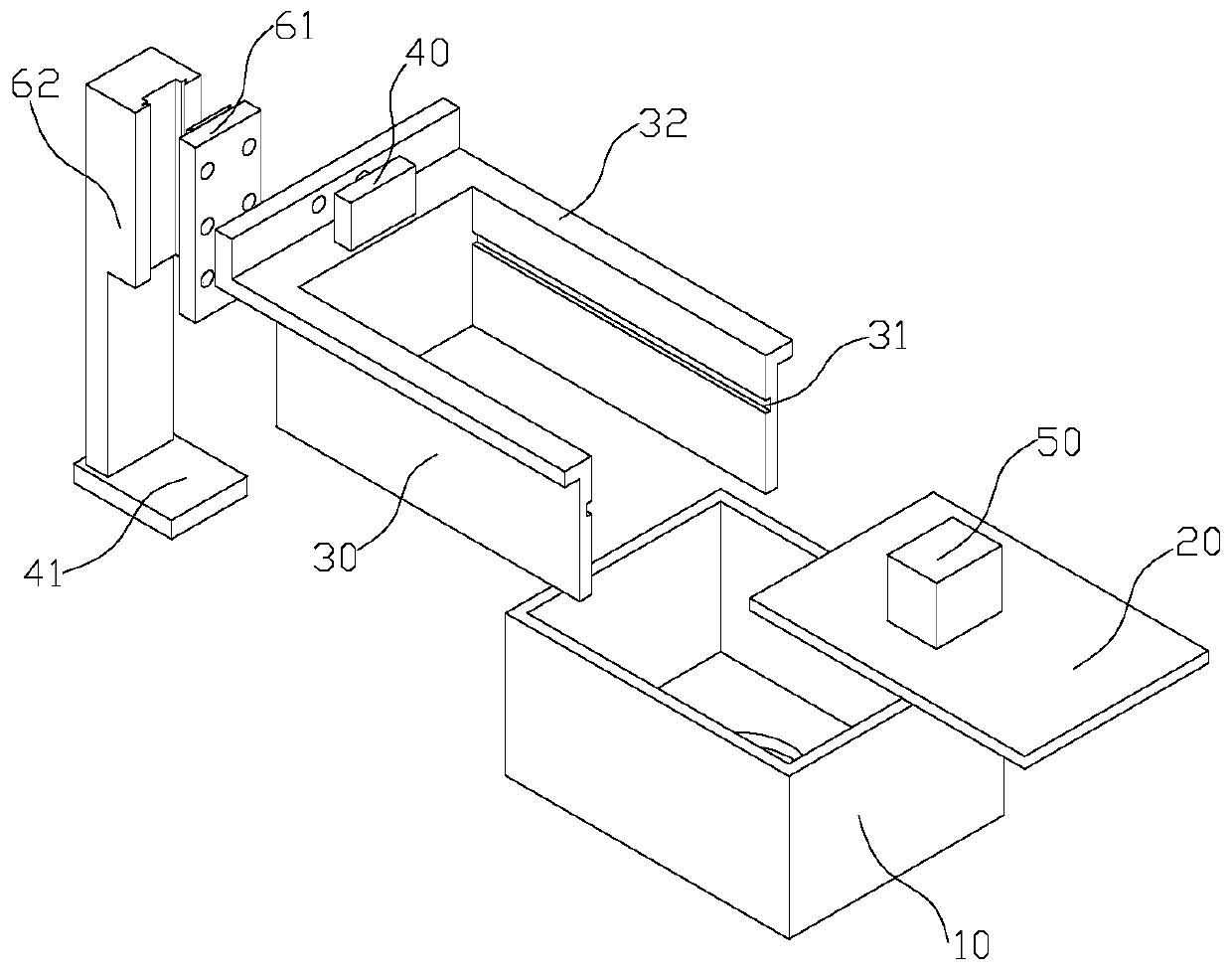

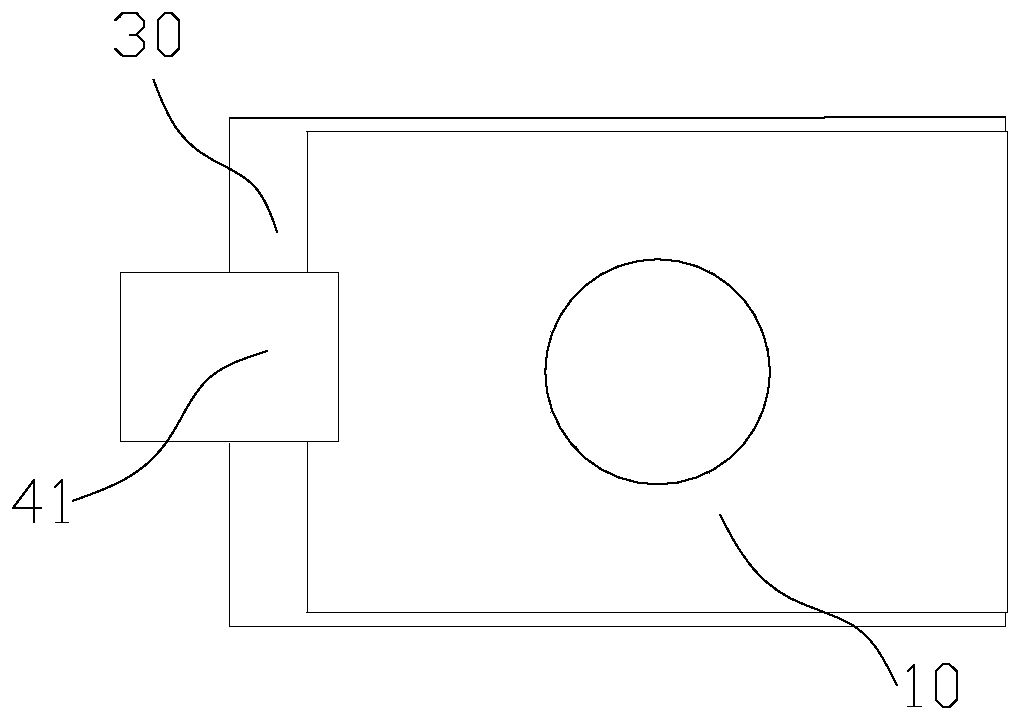

[0032] See attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 , what the present invention provides is a kind of crevice corrosion experimental device that can regulate the gap size in situ and in real time. This experimental device includes an experimental tank 10, a cover plate 20 and a range finder 40. The experimental device also includes an image acquisition instrument 50; The top of tank 10 has an open end, is provided with electrolyte solution in experiment tank 10, is provided with working electrode 33, reference electrode 34 and counter electrode 35 in electrolyte solution, and working electrode 33 enters electrolyte solution from the bottom of test tank 10, works Electrode 33, reference electrode 34 and counter electrode 35 are all connected with electrochemical workstation by wire, Figure 4 For the sake of brief introduction, the electrochemical workstation is not shown; the working electrode 33 is used to simulate the metal templa...

Embodiment 2

[0038] A crevice corrosion experimental method capable of in-situ and real-time regulation of the crevice size of the present invention comprises the following steps:

[0039] 1) Take the experimental tank 10, and install the working electrode 33, the reference electrode 34 and the counter electrode 35 in the experimental tank 10. In this embodiment, the working electrode 33 is a wire bundle electrode, and the wire bundle electrode packaged in advance is polished to 2000# , the diameter of the wire beam electrode is 40mm, and the diameter of the mounting hole at the bottom of the test tank 10 is also 40mm. The wire beam electrode is inserted into the test tank 10 through the mounting hole, and the wire at the bottom of the wire beam electrode is exposed, which is connected to the wire beam electrode potential current scanner. Interface, wire beam electrode material is U71Mn track steel, 10×10,

[0040] 2) Cover plate 20 is installed in the test tank 10. Cover plate 20 is a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com