Left and right double-spliced intensive bus duct starting end connecting plate

A technology of left and right double-split intensive and connecting boards, which is applied in the direction of fully enclosed busbar devices, can solve the problems of large space, occupying a large space, waste of space and cost, etc., and achieve the effect of improving the protection level and reducing space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

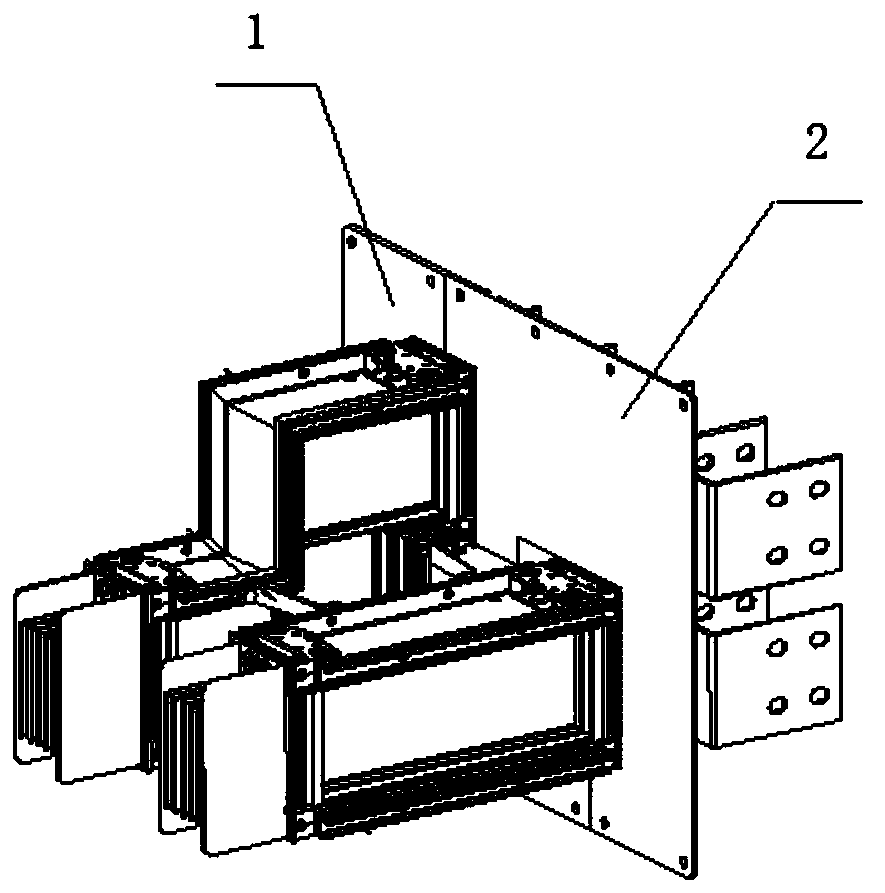

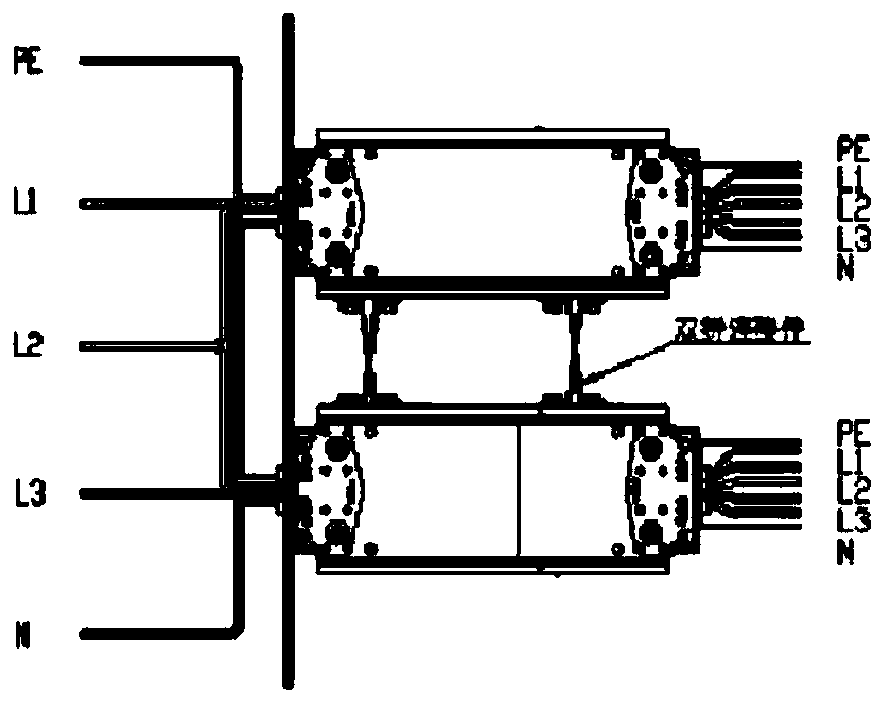

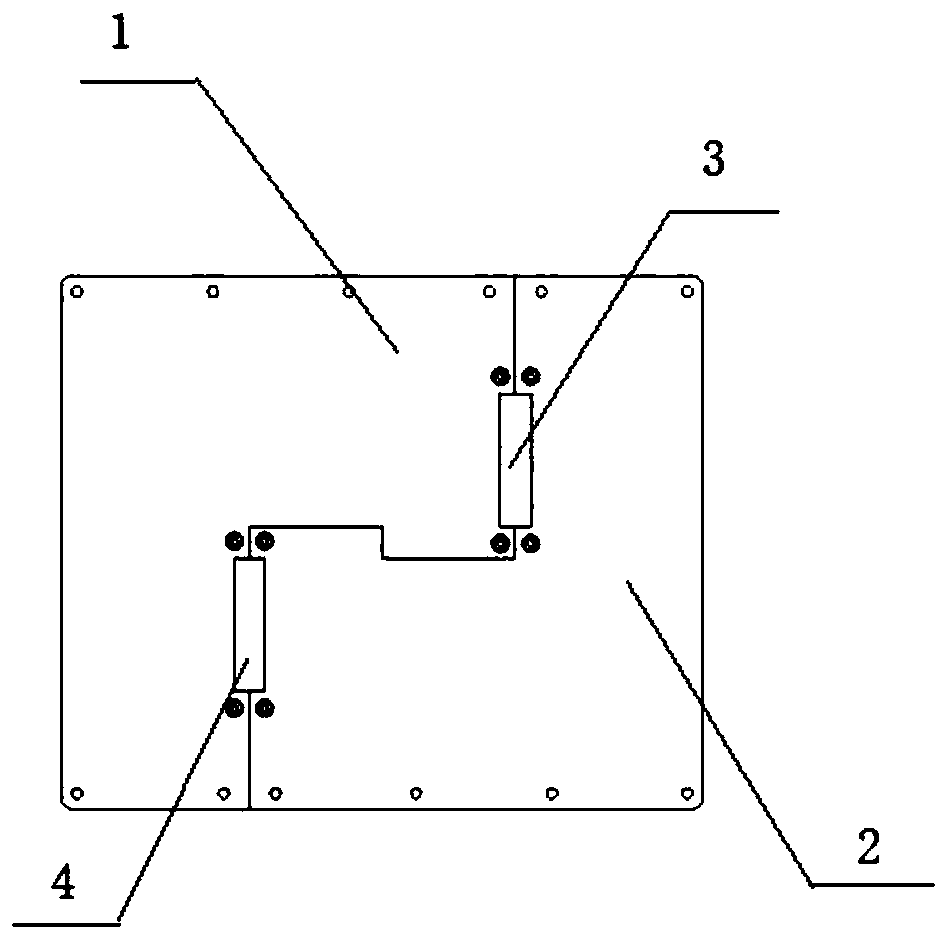

[0019] Such as figure 1 with figure 2 Shown is a connection effect diagram of the flange plate at the start end of a left and right double-split intensive busway of the present invention, as shown in image 3 with Figure 4 The above is a schematic diagram of the connection of the flange plates. The main part of the connecting plate at the starting end of the busway disclosed by the present invention consists of a first flange plate 1 and a second flange plate 2. The first flange plate 1 and the second flange plate A first busbar opening 3 is provided at the junction of the left half of the plate 2, a second busbar opening 4 is provided at the junction of the first flange plate 1 and the right half of the second flange plate 2, and the first busbar opening 3 and the second bus port 4 are arranged one above the other and one below the other.

[0020] The first flange plate 1 and the second flange plate 2 have the same shape and are assembled symmetrically.

[0021] The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com