An adjustable support for a tower crane

A tower crane, adjustable technology, applied in the field of brackets, can solve problems such as deterioration of stress conditions, difficult operation of the workshop, misplaced collisions, etc., to achieve the effect of avoiding deterioration of conditions, improving practicability, and moving smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

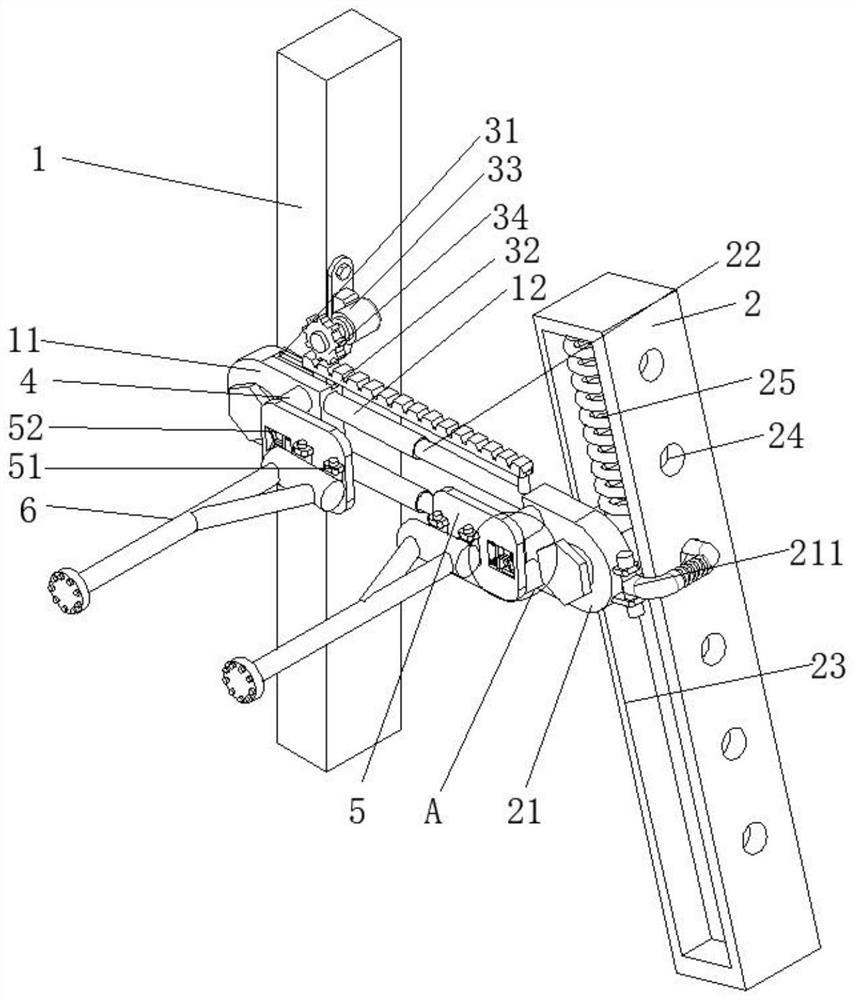

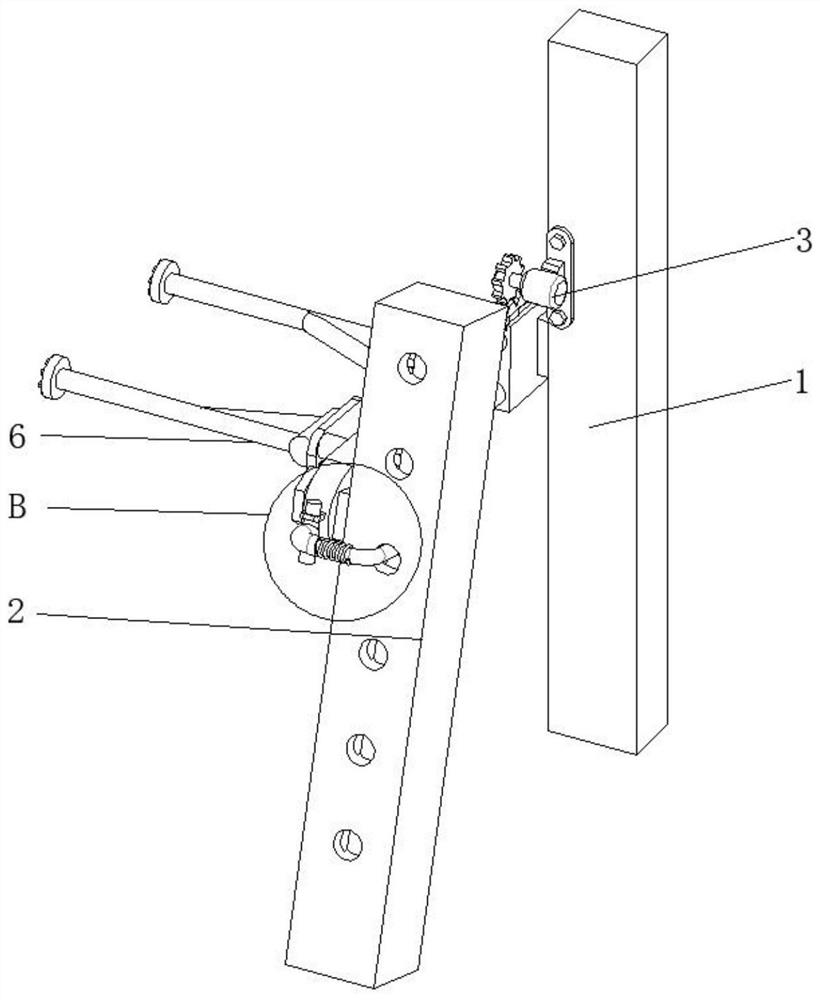

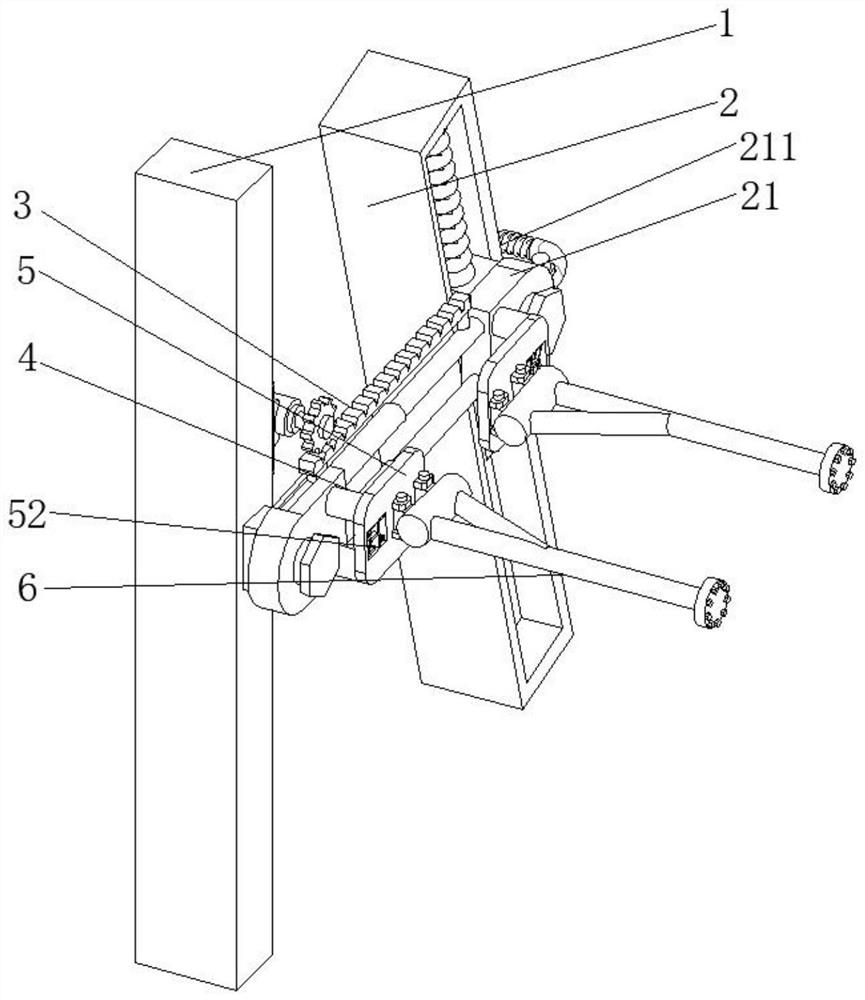

[0023] Example 1, such as Figure 1-5 As shown, the present invention provides an adjustable bracket for a tower crane, comprising a No. 1 A-frame 1 and a No. 2 A-frame 2. The outer surface of the No. 1 A-frame 1 is connected with a No. A limit groove 23 is provided on the side wall of the outer surface of the No. A frame 2, and the inner wall of the limit groove 23 is slidably connected with the second block 21, and the tops of the first block 11 and the second block 21 are fixedly installed with a mounting column 4 , the ends of the two mounting columns 4 away from the No. 1 block 11 and the No. 2 block 21 are fixedly mounted with a mounting plate 5, and the top and both sides of the mounting plate 5 are fixedly mounted with a No. 2 rotating shaft 51, and the mounting plate 5 passes through the No. 2 rotating shaft 51 Rotationally connected with bracket 6, one side wall of No. 1 A-frame 1 is fixedly equipped with adjusting structure 3, and the outer surfaces of No. 2 A-frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com