A sandwich structure electrode

A sandwich structure and electrode technology, applied in the field of large-capacity storage devices, can solve the problems of fast electrolyte consumption and unfavorable electrolyte infiltration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

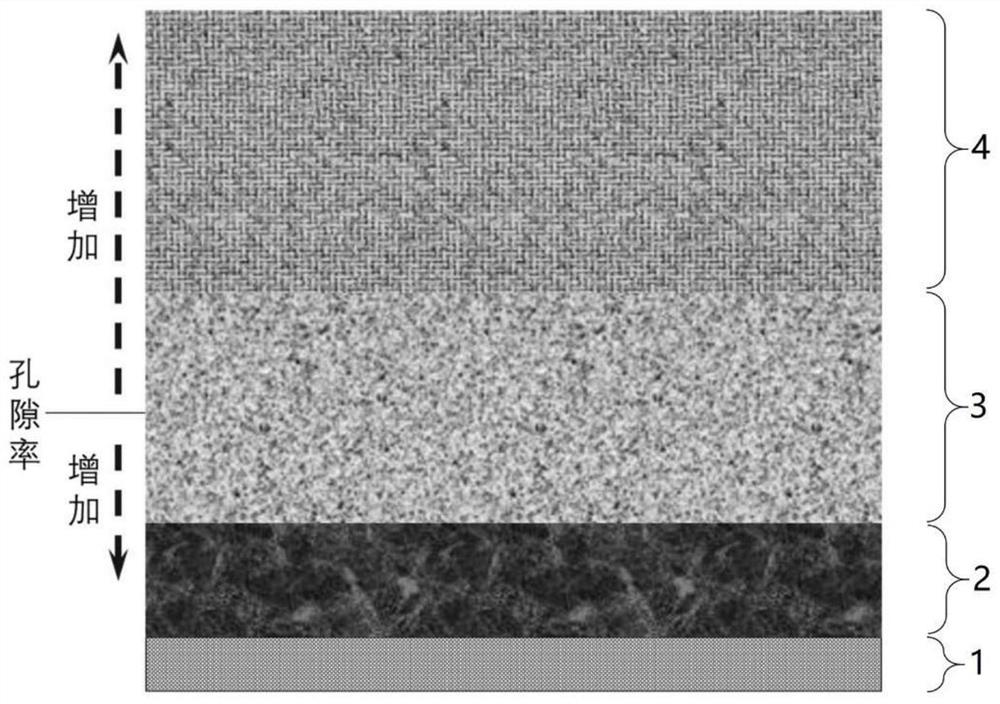

[0056] The electrode composition of lithium iron phosphate:SP:KS-6:PVDF=85:5:5:5 (wt.%) was mixed with NMP in a planetary mixer to form a uniform electrode slurry with a solid content of 41% A; The electrode composition of lithium iron phosphate:CNT:SP:PVDF=95:1:2:2 (wt.%) is mixed with NMP to form a uniform electrode slurry B with a solid content of 49%; Lithium iron phosphate: The electrode composition of SP:CNT:PVDF=93:2:2:3 (wt.%) was mixed with NMP to form a uniform electrode paste C with a solid content of 47%.

[0057] The slurry A was uniformly coated with 12 μm on the surface 1 of 15 μm aluminum foil with a blade coater, vacuum-dried at 150 ° C for 3 hours, and subjected to rolling treatment to obtain an electrode bottom layer 2 with a coating thickness of 10 μm, and the porosity was about 40%;

[0058] Then, the slurry B was uniformly coated on the surface of the electrode bottom layer 2 with a thickness of 60 μm, vacuum dried at 150 ° C for 10 hours, and then rolled...

Embodiment 2

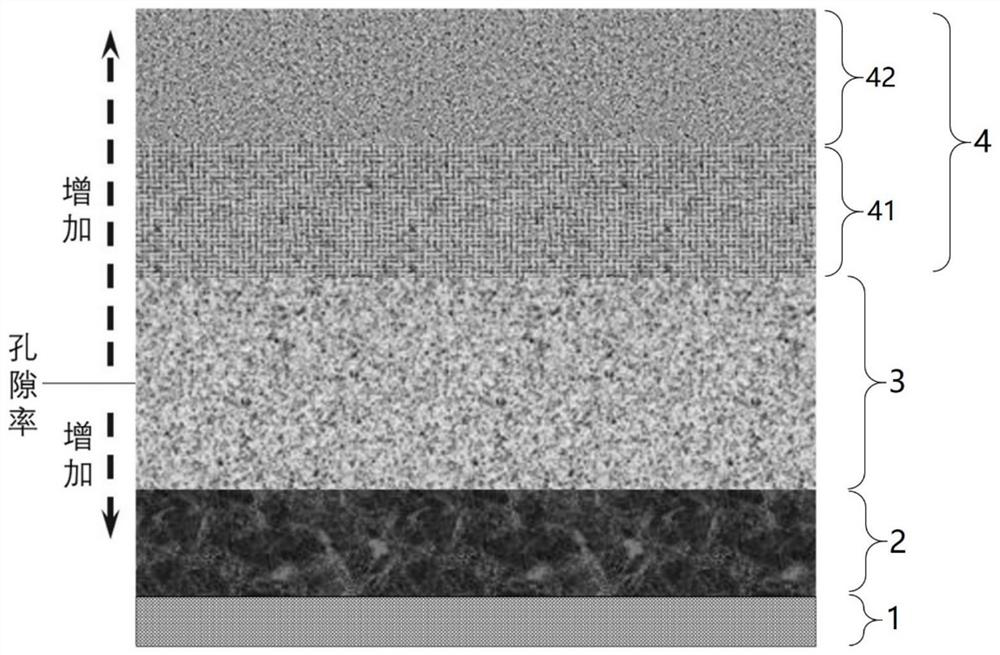

[0062] In a high-speed mixer, the electrode composition of lithium iron phosphate:SP:KS-6:PVDF=94:1.5:2:2.5 (wt.%) was mixed with NMP to form a uniform electrode slurry A with a solid content of 49%. The electrode composition of lithium iron phosphate:SP:KS-6:PVDF:ammonium bicarbonate=94:1:2:2:1 (wt.%) was mixed with NMP to form a uniform electrode slurry B with a solid content of 49%.

[0063] The slurry B was uniformly coated on the surface 1 of aluminum foil with a thickness of 15 μm by a doctor blade coater, and then vacuum-dried at 150 ° C for 3 hours to obtain an electrode bottom layer 2 with a coating thickness of about 40 μm; Thickness of slurry A, and then vacuum-dried at 120 ° C for 5 hours to obtain an electrode coated with the bottom layer and electrode intermediate layer 3, with a thickness of about 80 μm; Similarly, the surface of the dried electrode intermediate layer 3 was coated with slurry B of the same thickness , vacuum-drying at 150 °C for 3 hours to obtai...

Embodiment 3

[0066] The electrode composition of lithium iron phosphate:SP:KS-6:PVDF=94:1.5:2:2.5 (wt.%) was mixed with NMP in a planetary mixer to form a uniform electrode slurry with a solid content of 49% A; The electrode composition of lithium iron phosphate: SP: KS-6: PVDF: ammonium bicarbonate = 94:1:2:2:1 (wt.%) was mixed with NMP to form a uniform electrode slurry with a solid content of 49% Material B; the electrode composition of lithium iron phosphate: SP: KS-6: PVDF: ammonium bicarbonate = 93:1:2:2:2 (wt.%) was mixed with NMP to form a uniform electrode with a solid content of 49% Slurry C.

[0067] Slurry B was uniformly coated on the surface of 15μm aluminum foil with a blade coater, and then vacuum-dried at 150°C for 3 hours to prepare electrode bottom layer 2, with a coating thickness of about 40μm; then coated on the surface of the dried electrode bottom layer 2 Slurry A with the same thickness was vacuum-dried at 120°C for 5 hours to obtain an electrode coated with elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com