Foundation pit supporting structure

A technology for supporting structures and foundation pits, which is applied in foundation structure engineering, excavation, construction, etc., can solve the problems of inability to support the foundation pit support structure, poor support stability, and inability to support soil retaining boards, etc., to achieve high reliability , Guaranteed support effect, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

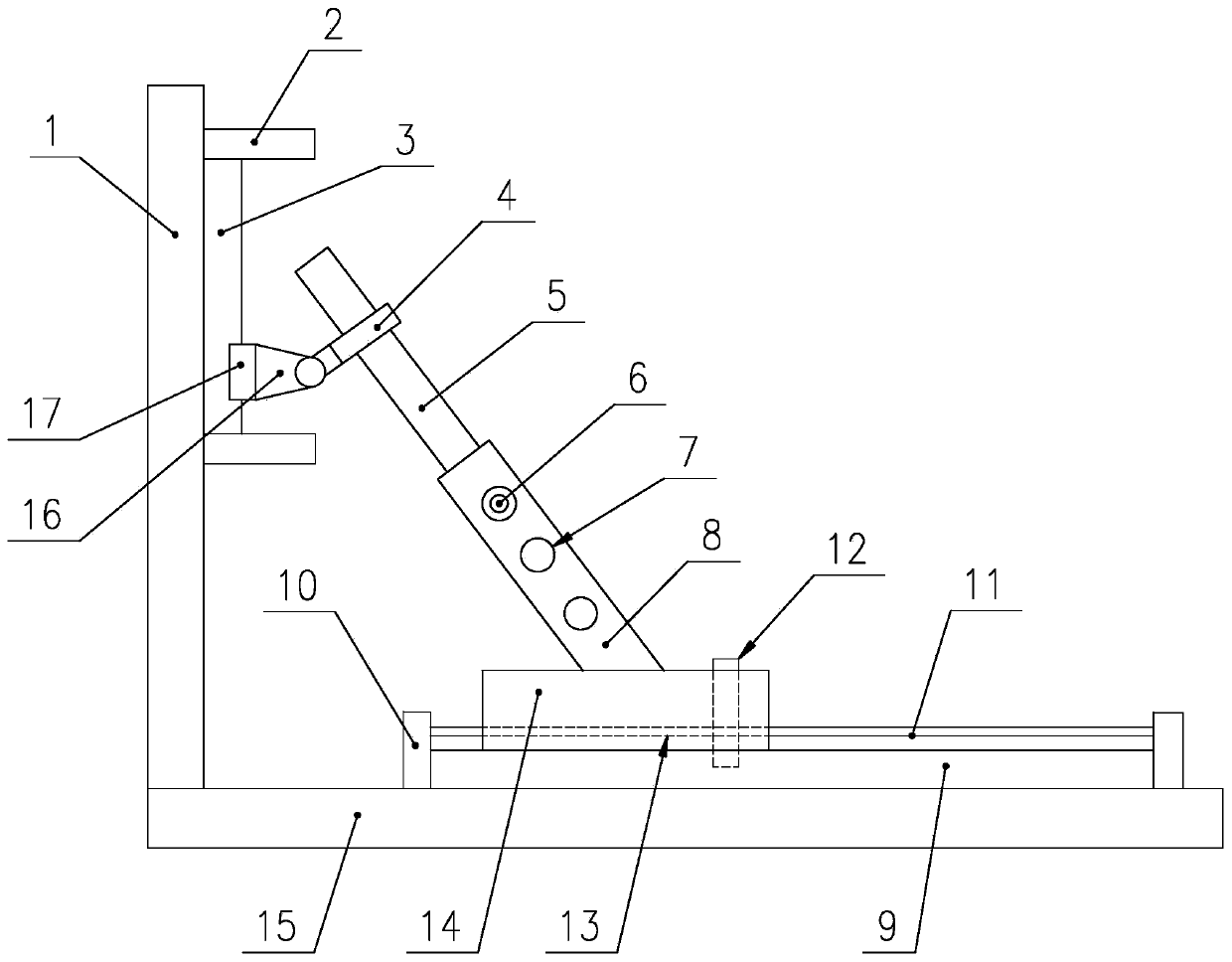

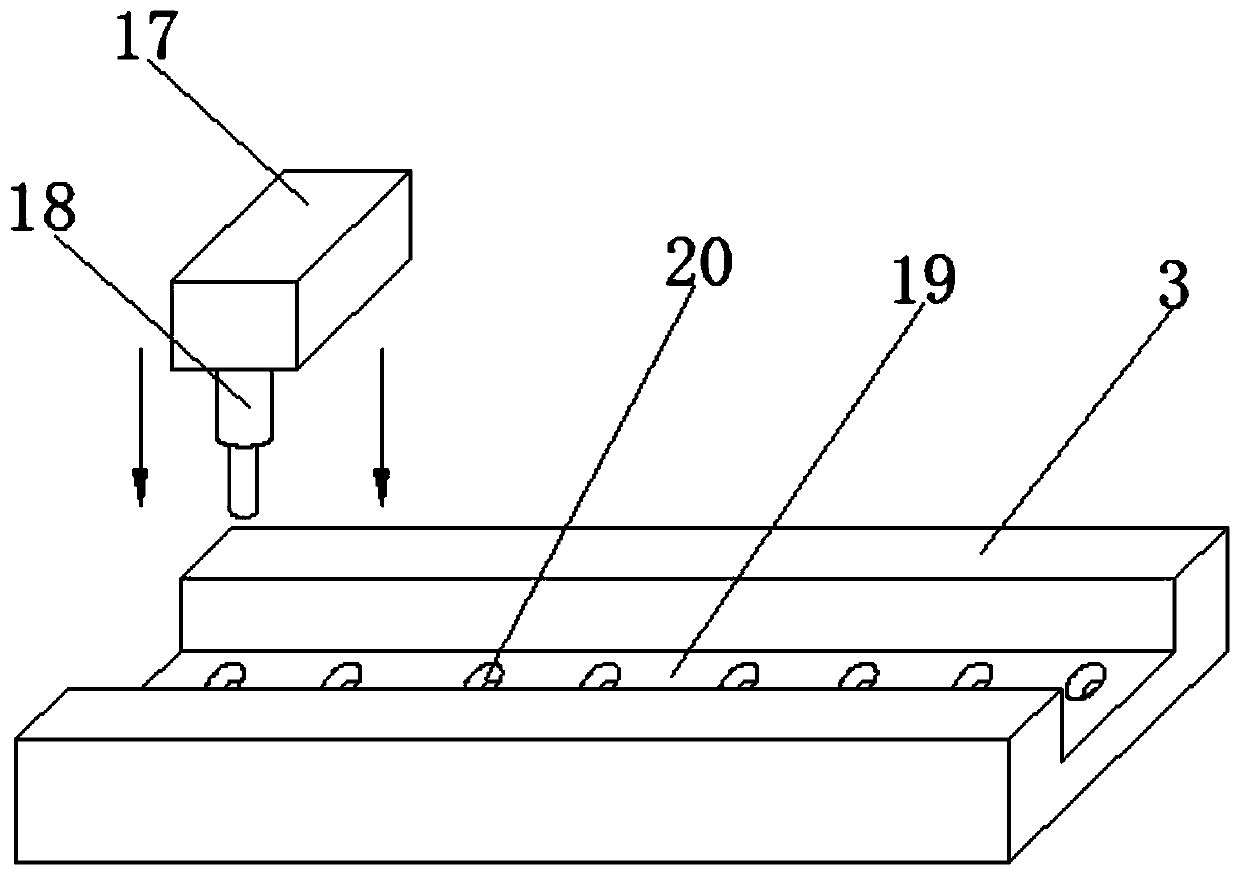

[0034] combine figure 1 with figure 2 As shown, the support structure of the foundation pit includes a soil retaining plate 1 blocked on the side wall of the foundation pit and a horizontal plate 15 arranged at the bottom of the foundation pit. A telescopic support device is arranged on the horizontal plate 15, and the telescopic support rod of the telescopic support device faces The outer wall of the earth retaining plate 1; the outer wall of the earth retaining plate 1 is provided with a first connecting plate 3, and the first connecting plate 3 is provided with a slider 17, which can be detached from parts of different heights on the first connecting plate 3 connection; the slider 17 is hinged with a fixed ring 4, and the fixed ring 4 is set on the telescopic support rod of the telescopic support device;

[0035]The outer wall of the first connecting plate 3 is provided with a chute 19, and the chute 19 is provided with at least two spacing holes 20 distributed up and dow...

Embodiment 2

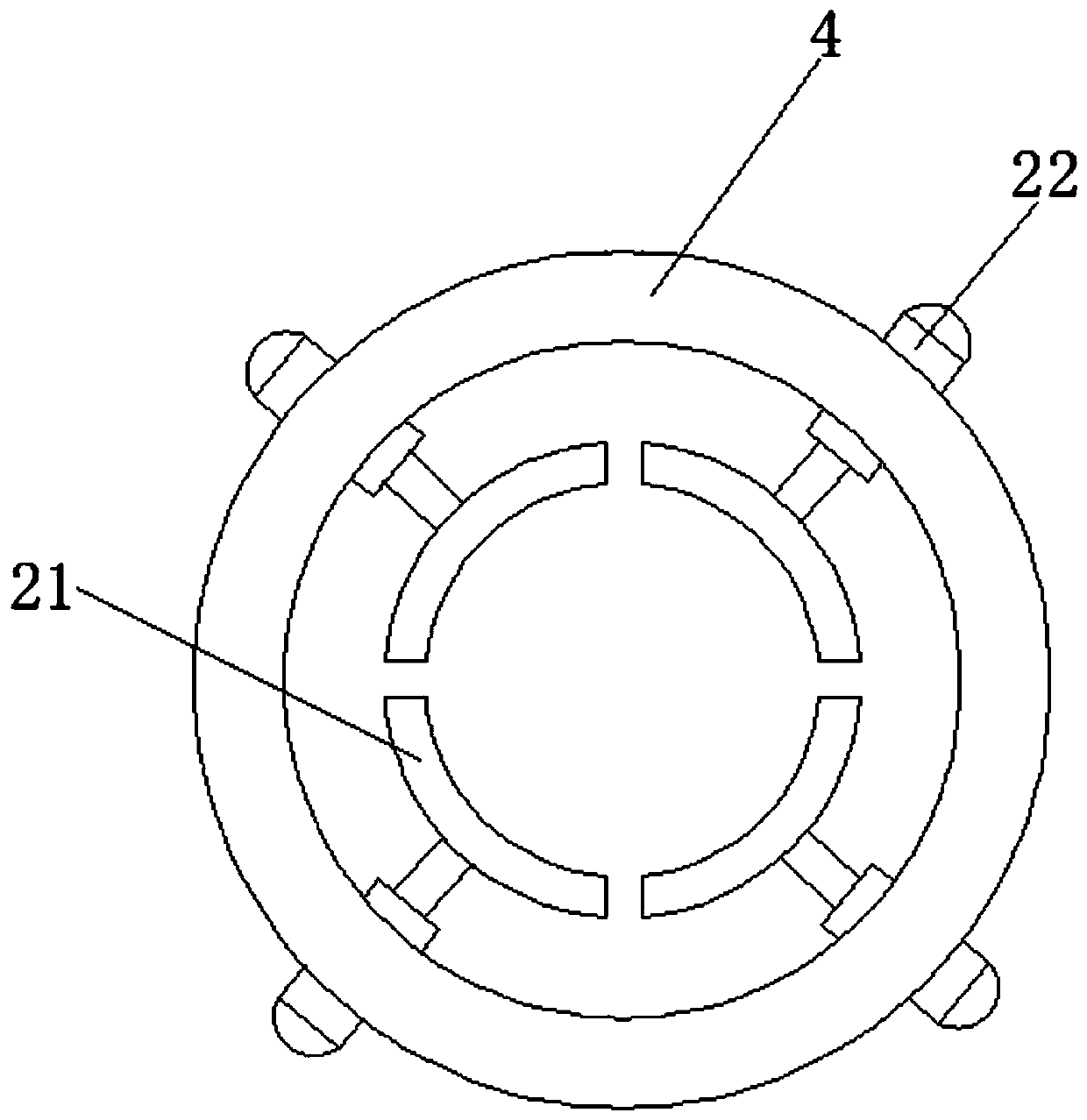

[0041] combine figure 1 with image 3 As shown, the supporting structure of the foundation pit includes a soil retaining plate 1 blocked on the side wall of the foundation pit and a horizontal plate 15 arranged at the bottom of the foundation pit. A telescopic support device is arranged on the horizontal plate 15, and the telescopic support rod of the telescopic support device faces The outer wall of the earth retaining plate 1; the outer wall of the earth retaining plate 1 is provided with a first connecting plate 3, and a slider 17 is arranged on the first connecting plate 3, and the sliding block 17 can be detached from parts of different heights on the first connecting plate 3 connection; the slider 17 is provided with a connection seat 16, the connection seat 16 is hinged with a fixed ring 4, and the fixed ring 4 is set on the telescopic support rod of the telescopic support device;

[0042] The peripheral wall of the fixed ring 4 is provided with a third electric push r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com