A high-speed sealing internal fluid static and dynamic characteristics measurement system

A technology of static and dynamic characteristics and measurement system, applied in machine/engine, non-variable-capacity pump, pump control, etc., can solve problems such as inability to experimentally measure working conditions, inability to combine theory and engineering practice, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

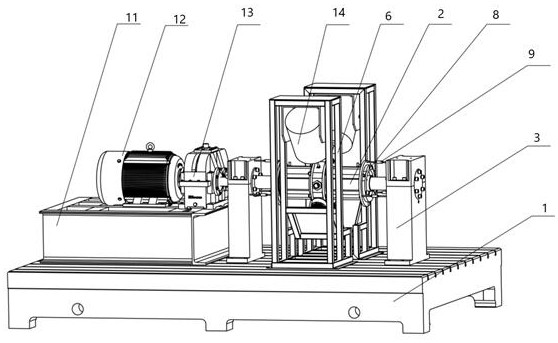

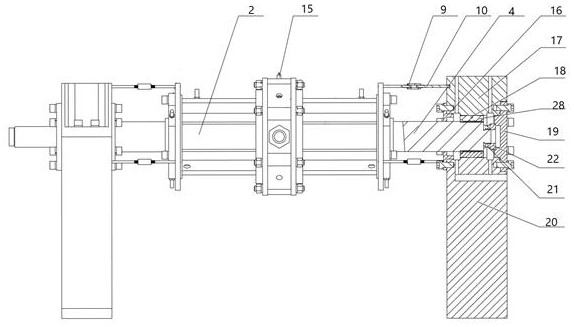

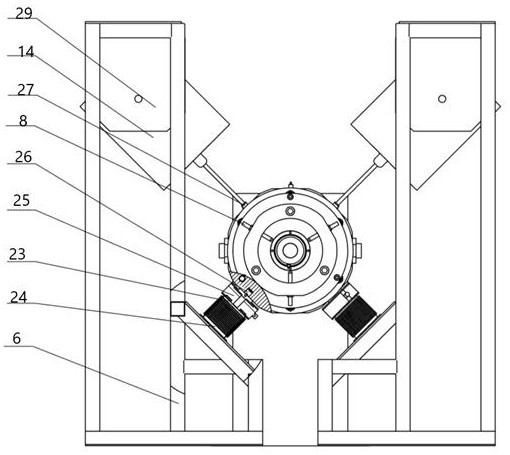

[0024] For specific implementation: see Figure 1 to Figure 3 , a high-speed sealed internal fluid static and dynamic characteristics measurement system, including a test base 1, a sealed cavity 2, a drive assembly and a bearing seat 3, the sealed cavity 2 is horizontally inserted with a main shaft 4 along the central axis, and the main shaft 3. Bearings 28 are respectively connected to the left and right ends. The bearings are installed in the bearing housing 3 fixed on the test base. One end of the main shaft passes through the bearing housing and is connected with the driving assembly. The bottom can be rotated, the sealing cavity is also provided with a spiral sealing sleeve, the spiral sealing sleeve includes a rotor and a stator matched with it, the rotor is fixedly connected to the main shaft, the stator is fixedly connected to the sealing cavity, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com