Pressure intensity experiment instrument detection equipment

A technology of experimental instruments and testing equipment, which is applied in the field of pressure experimental instruments and testing equipment, can solve problems such as troublesome operation, and achieve the effects of convenient marking, increasing the tightness of attachment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

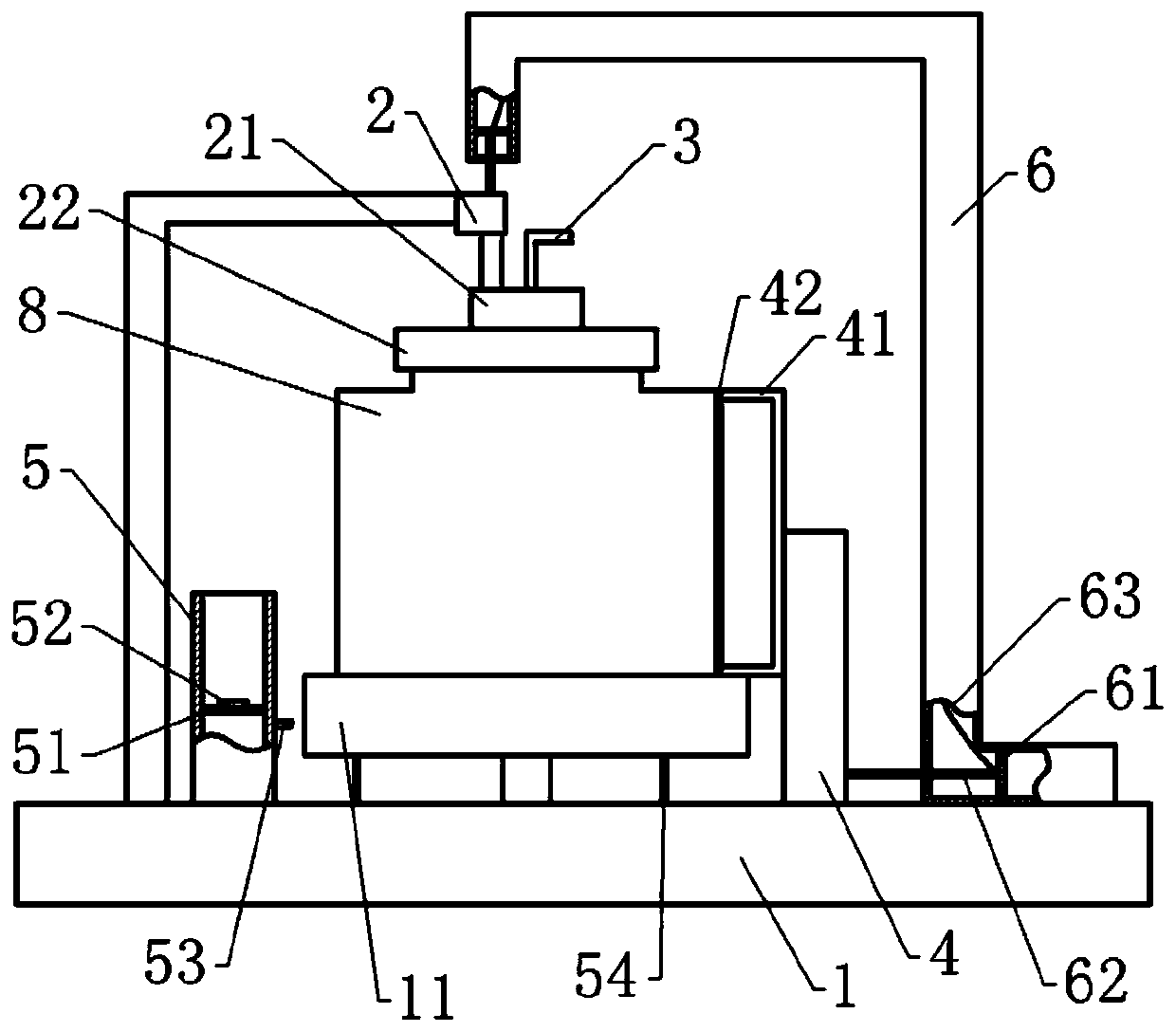

[0035] Pressure test instrument testing equipment, basically as attached figure 1 As shown, it includes a support platform 1, a detection part, an air intake part, an air suction part and a connecting piece 6. The support platform 1 is rotatably connected with a rotating block 11, and the upper surface of the rotating block 11 is provided with a mounting groove; the support platform 1 is embedded A motor is provided, and the drive shaft of the motor is fixed on the bottom of the rotating block 11 . Support frame 1 is also fixed with support frame, and lower pressure piece 2 is fixed on the support frame, and lower pressure piece 2 is the hydraulic expansion link that vertically arranges, and the bottom of hydraulic expansion link is fixed with lower pressing block 21, and the lower pressing block 21 The bottom is rotatably connected with a sealing cover 22 . Specifically, a rotating shaft is coaxially fixed on the top of the sealing cover 22 , and the rotating shaft passes th...

Embodiment 2

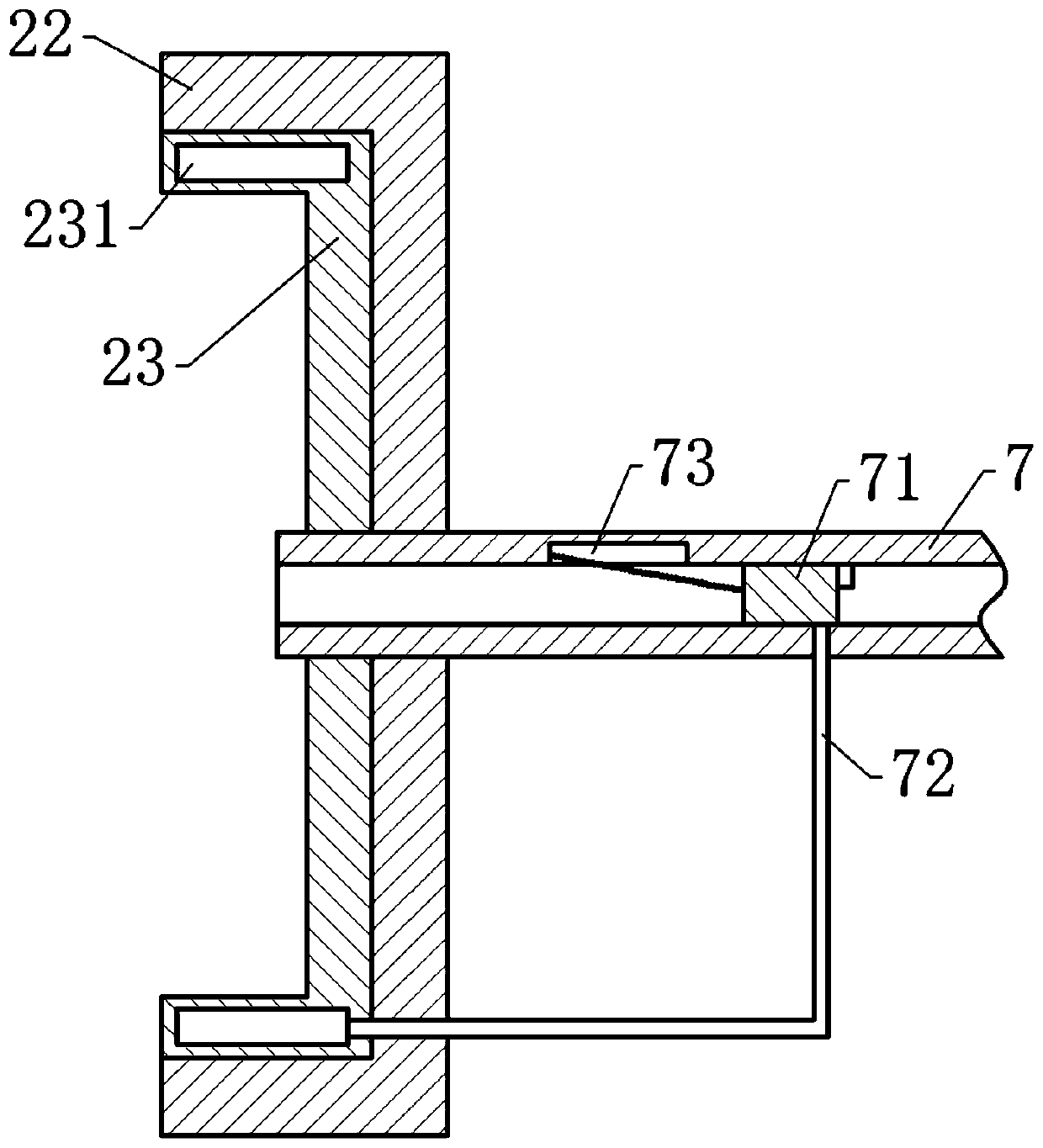

[0049] Embodiment 2 differs from Embodiment 1 only in that, as figure 2 As shown, the bottom of the sealing cover 22 is also fixed with a flexible sealing layer 23, and the flexible sealing layer 23 is provided with a cavity 231. The cavity 231 is connected with an inflatable part, and the inflatable part runs through the rotating shaft and is connected with the rotating shaft. Inflatable head 7. A sealing plate 71 is horizontally slidably connected in the inflatable head 7 , the inner wall of the inflatable head 7 is located at the left side of the sealing plate 71 and is provided with an air inlet gap 73 , and a spring is arranged between the air inlet gap 73 and the sealing plate 71 . An air duct 72 communicates with the inflatable head 7 below the sealing plate 71 , and the left end of the air duct 72 communicates with the cavity 231 in the flexible sealing layer 23 . The right end of the inflation head 7 communicates with the intake pipe 3 .

[0050] The specific implem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com