A solid wood water transfer printing and graining device for making furniture

A technology of water transfer printing and solid wood, applied in transfer printing, rotary printing machine, printing, etc., can solve the problems of low work efficiency and labor, and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

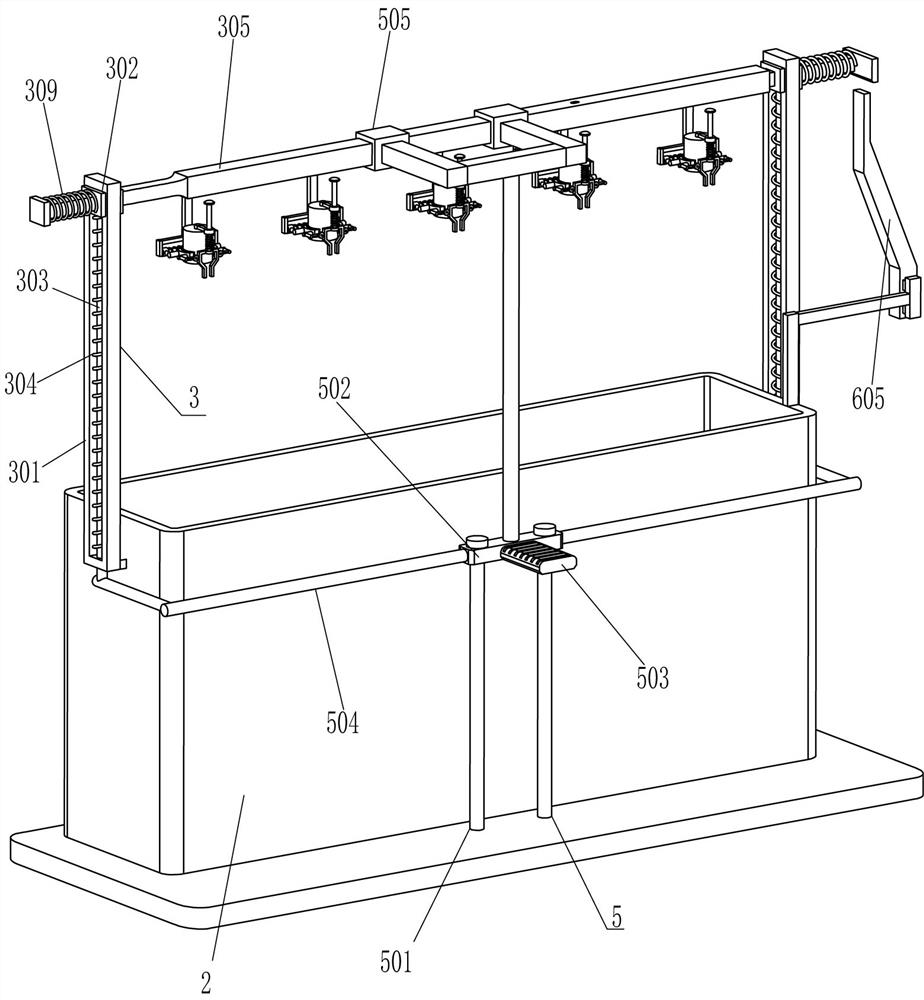

[0023] see Figure 1-Figure 4 , a solid wood water transfer printing device for making furniture, including a bottom plate 1, a frame body 2, a moving component 3 and a clamping component 4, a frame body 2 is installed in the middle of the top rear side of the bottom plate 1, and the outer side of the frame body 2 A moving assembly 3 is arranged between the left and right sides, and clamping assemblies 4 are evenly spaced on the moving assembly 3 .

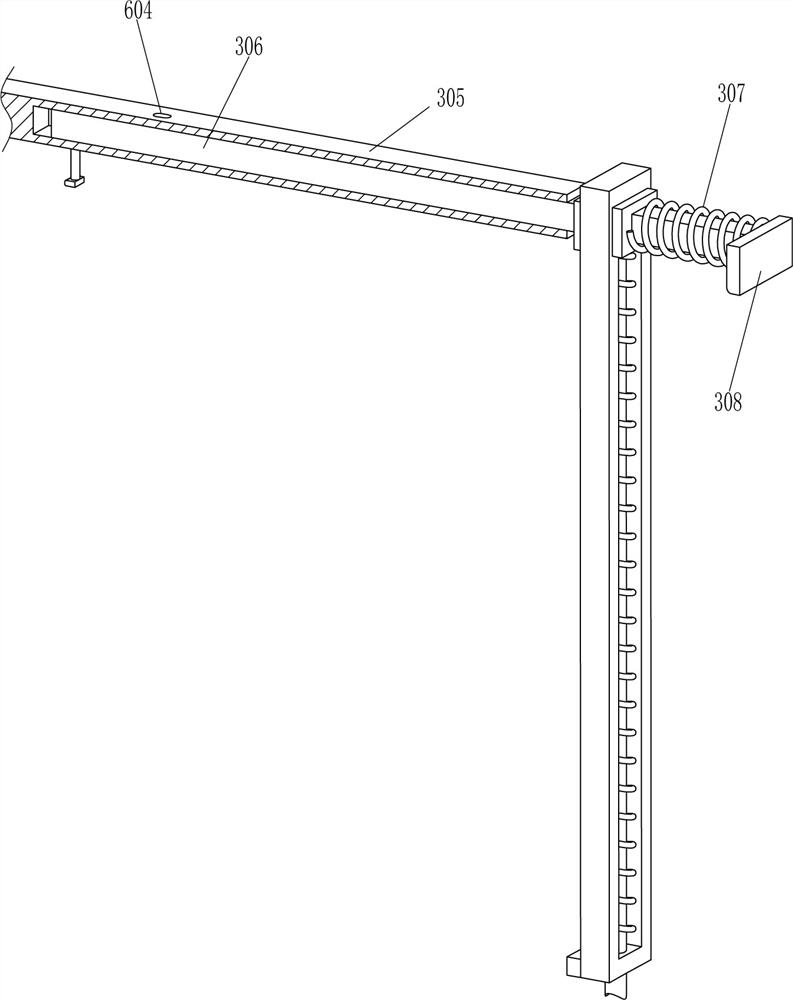

[0024] The mobile assembly 3 includes a guide frame 301, a first slider 302, a guide rod 303, a first spring 304, a mounting rod 305, a first slide rod 306, a second spring 307, a contact block 308 and a third spring 309, and the frame body 2. A guide frame 301 is fixedly connected to the upper parts of the outer left and right sides. The guide frame 301 is slidably provided with a first slide block 302. The guide rod 303 is connected with a guide rod 303 slidingly in the middle of the bottom of the guide frame 301. The top end of...

Embodiment 2

[0030] see figure 1 and figure 2 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a pedal assembly 5 is also included, and the pedal assembly 5 includes a second slide bar 501, a second slide block 502, a pedal 503, and a connecting frame 504 and the guide sleeve 505, two second sliding rods 501 are fixedly connected to the middle front side of the top of the bottom plate 1, and a second sliding block 502 is provided slidingly between the two second sliding rods 501, and the left and right sides of the second sliding block 502 All are fixedly connected with a connecting frame 504, the rear side of the top of the connecting frame 504 is fixedly connected with the bottom end of the guide rod 303, the middle part of the front side of the second slider 502 is fixedly connected with a pedal 503, and a sliding guide sleeve 505 is provided on the mounting rod 305. The middle of the top of the second sliding block 502 is fixedly connecte...

Embodiment 3

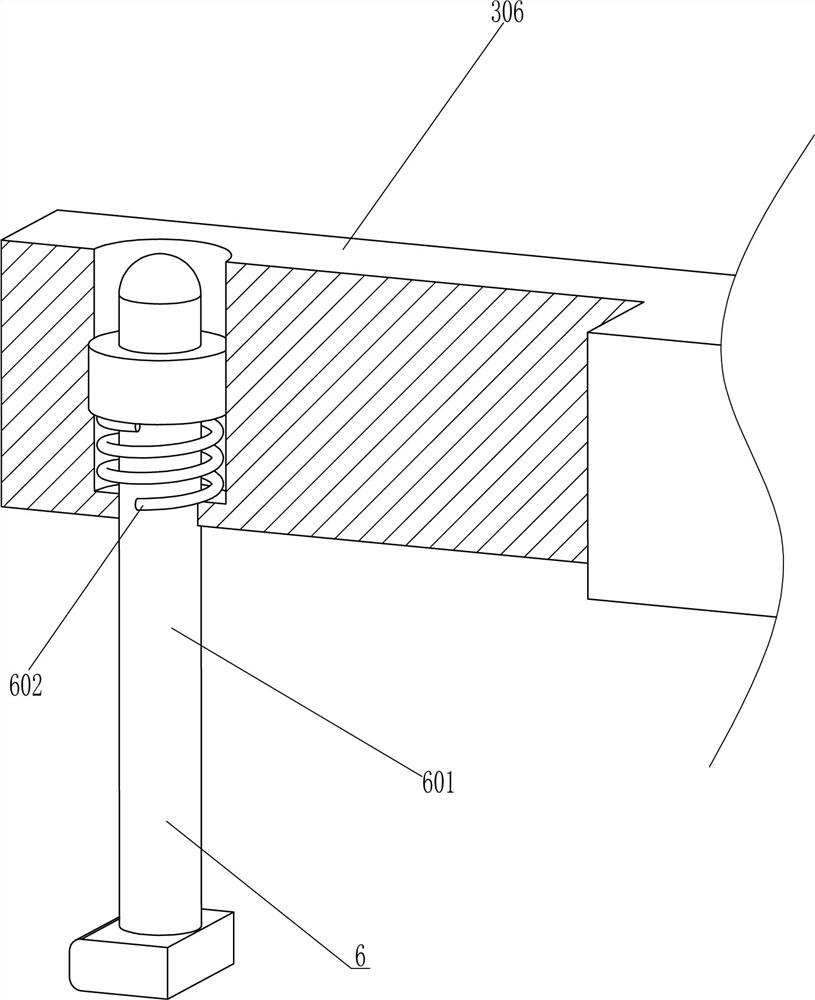

[0033] see figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6 Compared with Embodiment 1 and Embodiment 2, the main difference of this embodiment is that in this embodiment, a shaking assembly 6 is also included. The left part of the first sliding bar 306 is slidingly provided with a locking bar 601, a sixth spring 602 is wound between the upper part of the locking bar 601 and the inside of the first sliding bar 306, and the bottom end of the locking bar 601 runs through the mounting bar 305 to slide and cooperate with it. , the bottom right side of the right guide sleeve 505 is affixed with a wedge-shaped block 603, the wedge-shaped block 603 cooperates with the clamping rod 601, and the front part of the right side of the top of the frame body 2 is affixed with a special-shaped rod 605, and the special-shaped rod 605 cooperates with the contact block 308. A through hole 604 is opened on the right side of the top of the rod 305 , and the through hole 604 cooperate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap