Cloth tube holder for mask production equipment

A technology of production equipment and cloth tube, which is applied in the field of cloth tube fixing frame for mask production equipment, which can solve the problems of cloth wrinkles, poor flanging effect, and inability to guarantee the setting position, etc., and achieve the effect of convenient feeding and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below according to the accompanying drawings and specific embodiments.

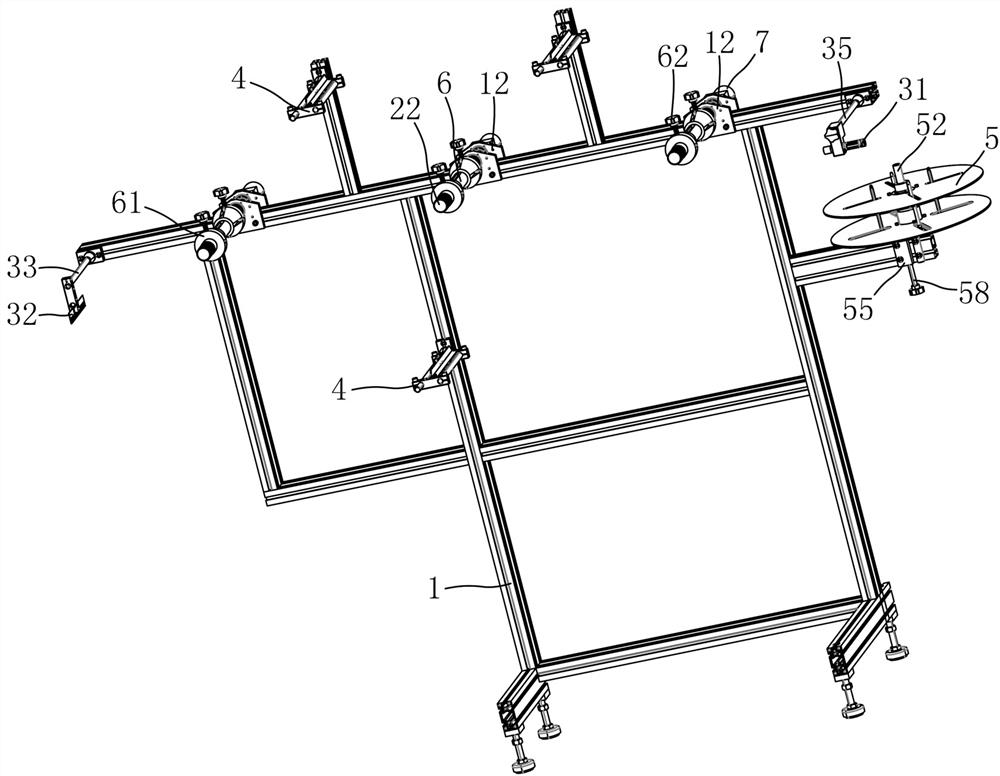

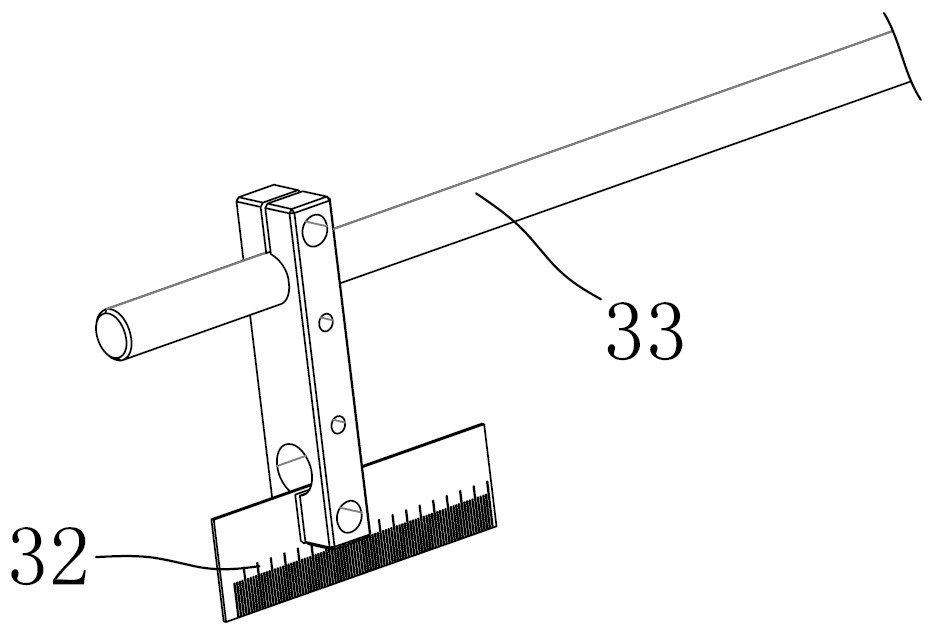

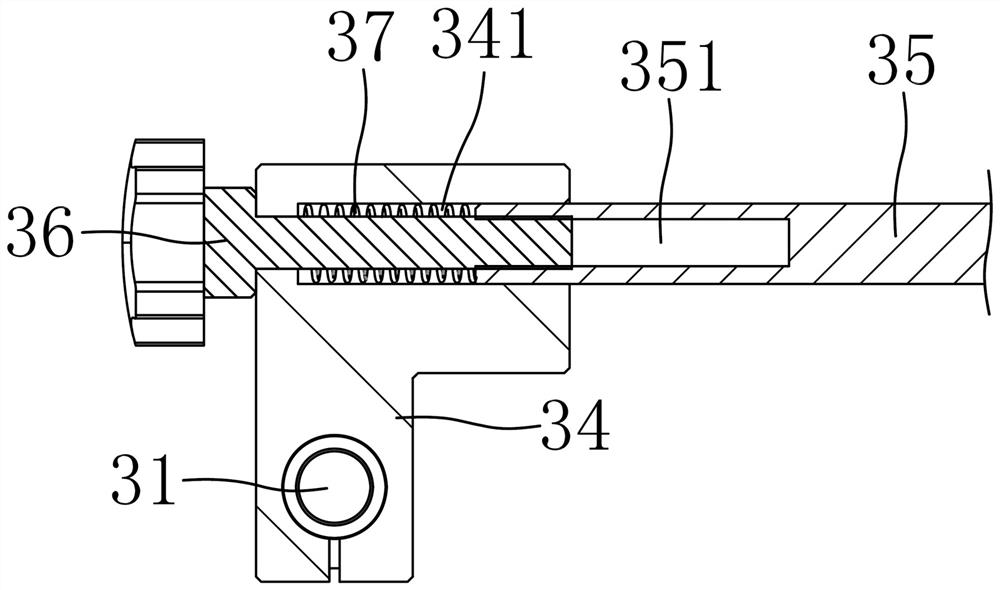

[0035] Depend on figure 1 , figure 2 , image 3 , Figure 7 , Figure 8 and Figure 9 As shown, a cloth tube fixing frame for mask production equipment of the present invention comprises a frame body 1, three fixed shafts 2 arranged side by side are arranged on the frame body 1, and a fixed tube 6 is sleeved on the fixed shaft 2, and the fixed shaft Located on the same side of the left and right sides of the frame body 1, the fixed shafts 2 are arranged along the left and right directions, and the axes of the fixed shafts 2 are arranged parallel to each other. The side of the frame body 1 with the fixed shaft 2 is provided with a detection component, and the detection component includes a laser transmitter. 31 and the reference piece 32 , the fixed shaft 2 is located between the laser emitter 31 and the reference piece 32 , the laser emitter 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com