A kind of titanium alloy composite coating for engine blade and preparation method thereof

A technology for engine blades and composite coatings, applied in metal material coating processes, coatings, heating inorganic powder coatings, etc. The effect of controllable thickness and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

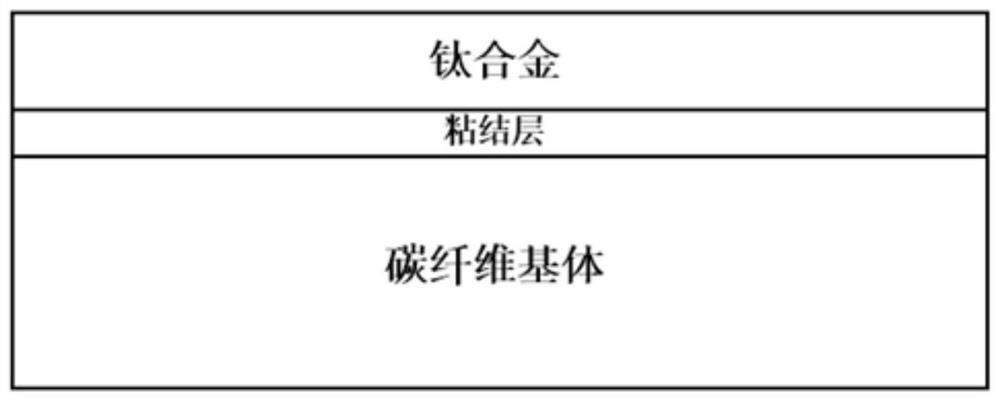

Image

Examples

Embodiment 1

[0033] In this example, the base material is selected as carbon fiber reinforced polyetheretherketone with a thickness of about 20mm×20mm×2mm, and a tin coating with a thickness of 100-200 μm and a titanium alloy coating with a thickness of 400-800 μm are successively deposited on the surface of the base. The specific preparation process is as follows:

[0034] 1. Screen the metal powder raw material with a 350-mesh filter sieve to ensure that the particle size is uniform and meet the requirements for cold spraying. After drying at 120°C for 1 hour, a dry powder that can be sprayed is obtained.

[0035] 2. The carbon fiber reinforced composite matrix is ultrasonically cleaned in acetone for 5 to 10 minutes, and then dried to obtain a matrix with a clean surface.

[0036] 3. Spray tin powder on the surface of the substrate in advance to prepare the bonding layer. The spraying method is cold spraying. The specific process parameters are: the spraying gas is nitrogen, the main ...

Embodiment 2

[0040] In this example, the base material is carbon fiber reinforced epoxy resin with a thickness of about 20mm×20mm×2mm, and an aluminum coating with a thickness of 100-200 μm and a titanium alloy coating with a thickness of 400-800 μm are successively deposited on the surface of the base. The preparation process is as follows:

[0041] 1. Screen the metal powder raw material with a 300-mesh filter sieve to ensure that the particle size is uniform to meet the requirements of cold spraying, and dry it at 120°C for 1 hour to obtain a dry powder that can be sprayed.

[0042] 2. Place the carbon fiber reinforced epoxy substrate in acetone for ultrasonic cleaning for 5-10 minutes, and dry it to obtain a substrate with a clean surface.

[0043] 3. Spray aluminum powder on the surface of the coating in advance to prepare the bonding layer. The spraying method is cold spraying. The specific process parameters are: the spraying gas is nitrogen, the main gas pressure of cold spraying i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com