Water conservancy project retaining wall

A technology for water conservancy projects and retaining walls, applied in water conservancy projects, infrastructure engineering, artificial islands, etc., can solve problems such as blockage of filter screens and affect the normal drainage work, so as to protect the retaining walls and reduce the difficulty of maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

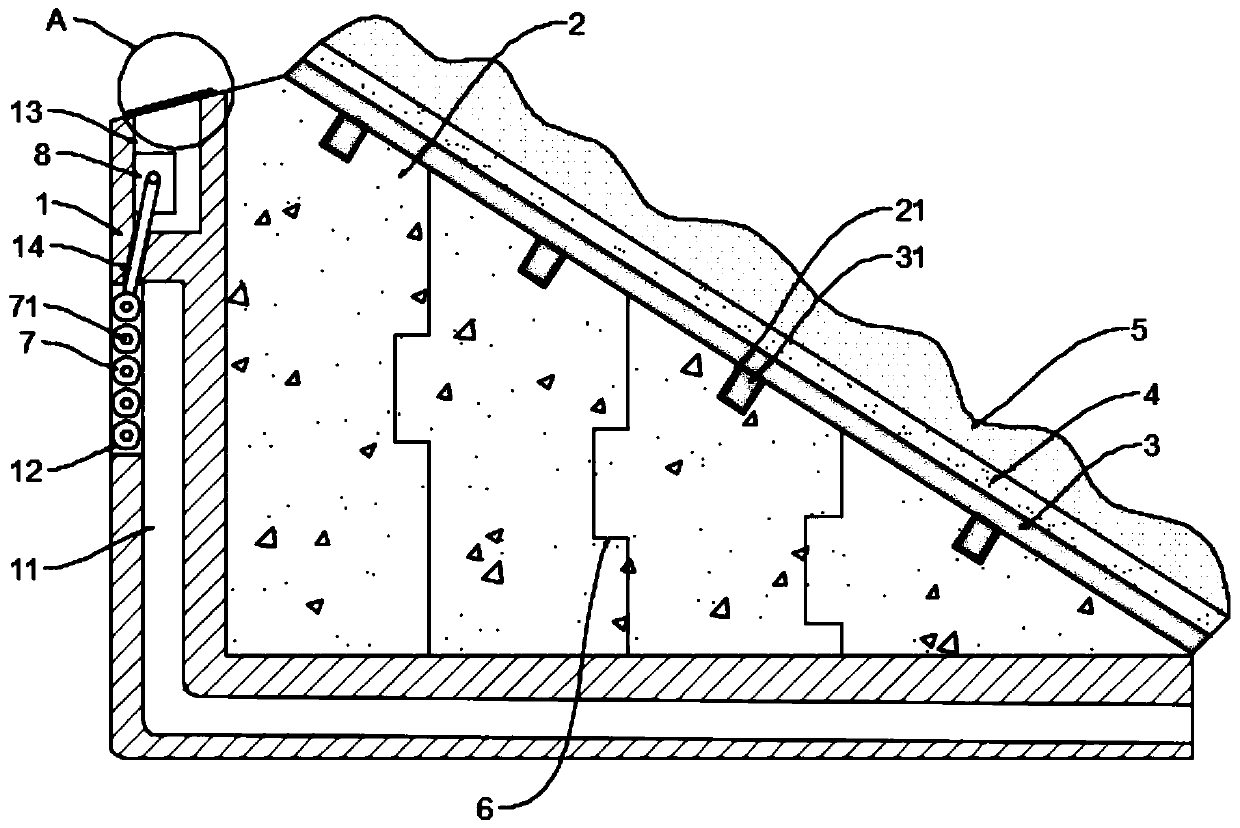

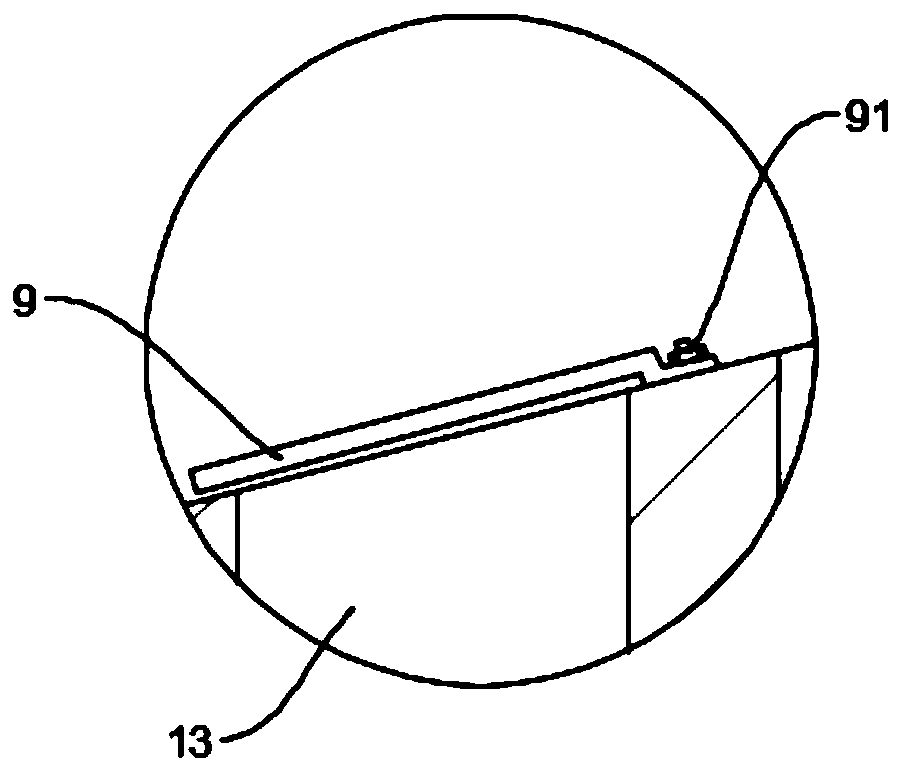

[0022] See Figure 1~3 In the embodiment of the present invention, a retaining wall for a water conservancy project includes a mounting seat 1 and a retaining wall provided on the mounting seat 1. The mounting seat 1 is provided with a connected drainage channel 11 and a water inlet 12, and the water inlet 12 is arranged on the side of the mounting seat 1 close to the foundation soil; a plurality of rotating rollers 7 arranged equidistantly are installed in the water inlet 12, and the rotating rollers 7 are rotatably connected to the water inlet 12 through a rotating shaft 71, and adjacent rotating rollers There is a gap between 7 so that water can circulate. The adjacent rotating shafts 71 are connected by a first belt pair transmission. The mounting seat 1 is equipped with a driving device 8 for driving one of the rotating shafts 71 to rotate. During normal operation, the water It flows into the drainage channel 11 through the gap between the rollers 7 for normal drainage. Wh...

Embodiment 2

[0027] The embodiment of the present invention expands its functions on the basis of embodiment 1. Specifically:

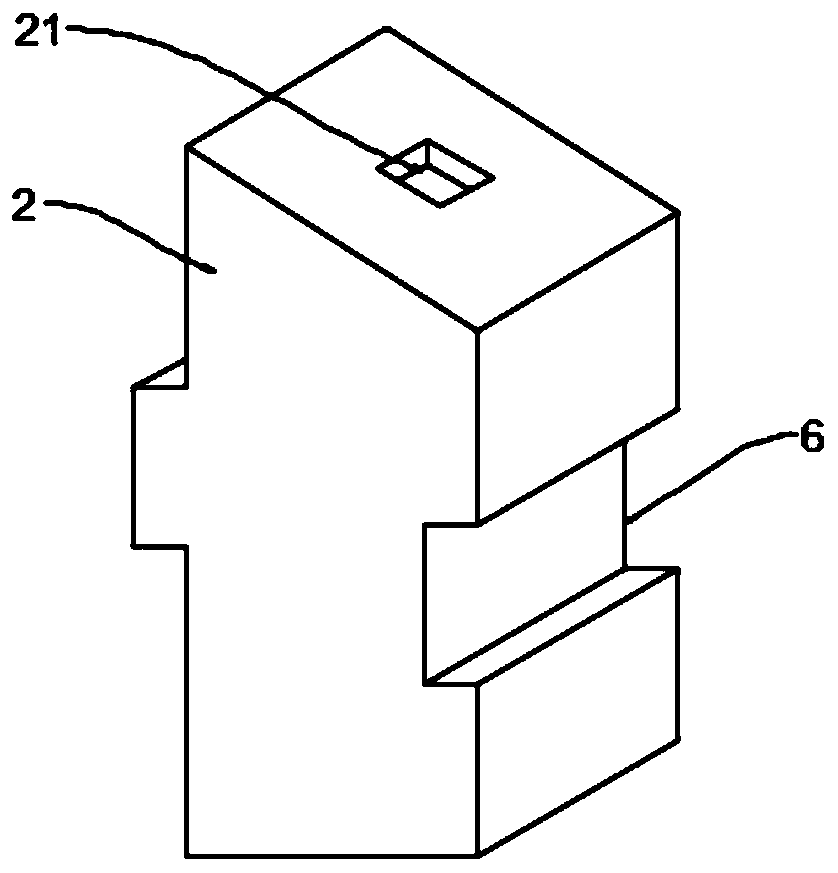

[0028] The retaining wall is composed of multiple wall units 2. The wall unit 2 is fixed on the mounting base 1 by bolts, so that when the wall is partially damaged, only one of the wall units 2 needs to be replaced. Perform overall disassembly.

[0029] In order to ensure the connection strength of the adjacent wall units 2, in this embodiment, the adjacent wall units 2 are connected by a locking structure 6, and the locking mechanism 6 includes a recess integrally formed in one of the wall units 2. The concave portion and the convex portion integrally formed on the other wall unit 2 are embedded in the concave portion and the convex portion. The cooperating arrangement of the concave portion and the convex portion can improve the connection strength of the adjacent wall unit 2.

[0030] Further, the outer surface of the retaining wall is provided with a waterproof lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com