Water tank structure for load test, test device and test method

A technology of load test and test method, applied in basic structure engineering, basic structure test, construction, etc., can solve the problems of inconvenient transportation and loading and unloading, long service cycle, etc., and achieve convenient and fast transportation and loading and unloading, safe stacking, and avoid waste. Time and manpower and the effect of inconvenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

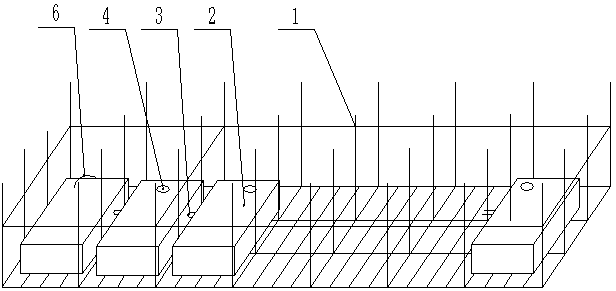

[0025] The present embodiment provides a kind of water tank structure that is used for load test, as figure 1 As shown, it includes several water tanks 2 that are evenly distributed in layers and stacked on the support 1, and the adjacent water tanks 2 on each layer are connected through connecting water pipes 3, and each water tank 2 is provided with a water inlet 4 and a water discharge port 5 , the detachable sealing cover is installed on the 5 ends of the water discharge port, and the water inlet 4 is located on the top surface of the water tank 2 and is connected to the water pump through the detachable water inlet pipe 6 .

[0026] Both the detachable water inlet pipe 6 and the water outlet 5 ends are equipped with automatic flow control devices. The water inlet 4 of at least one of the water tanks 2 on each floor is connected to the water pump through a detachable water inlet pipe 6 . All adjacent water tanks 2 are connected by connecting plates, and the connecting pla...

Embodiment 2

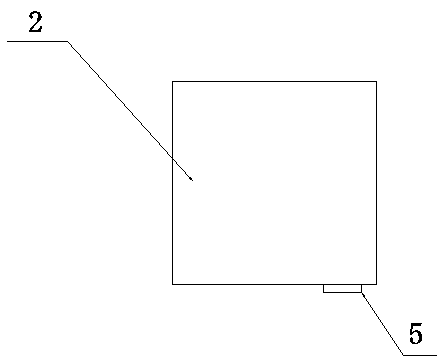

[0039] On the basis of Example 1, in order to facilitate uninstallation, such as figure 2 As shown, in this embodiment, the drain port 5 is opened on the bottom surface of the water tank 2 . Specifically, when unloading, open the drain port 5 on the bottom plate of each water tank 2, the water in the water tank 2 flows out from the drain port, and because the drain port 5 is provided on the bottom surface of the water tank 2, it can ensure that the water in the water tank 2 is completely unloaded.

Embodiment 3

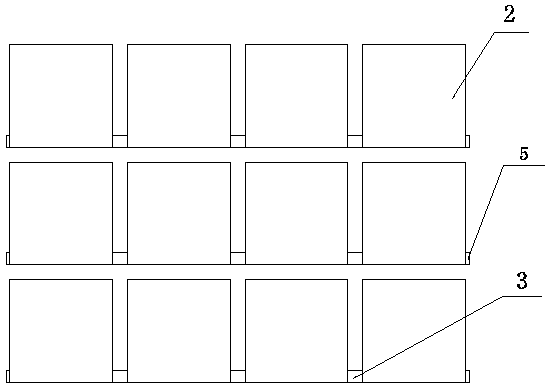

[0041] On the basis of Example 1, such as image 3 and Figure 4 As shown, each side wall of the water tank 2 is respectively provided with a drain opening 5 near the bottom plate, and the drain openings 5 on the opposite side walls of the two adjacent water tanks 2 on each floor are used as connection ports for connecting the water pipes 3 .

[0042] Specifically, this embodiment takes a rectangular water tank as an example (it is not limited thereto, it can also be a water tank of other shapes), the top surface of each rectangular water tank is provided with a water inlet 4, and the water inlet 4 is connected to a detachable water inlet pipe 6, The detachable water inlet pipe 6 is connected to the running water pipe on the construction site, or the detachable water inlet pipe 6 is connected to the water pump, and the water pump is placed in the water storage tank or the water storage tank; in particular, each of the four side walls of the rectangular water tank is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com