Medium and high-rise building lighting system

A technology for lighting systems and high-rise buildings, applied in buildings, ventilation systems, lighting devices, etc., can solve problems affecting living comfort, temperature rise, etc., achieve good energy-saving effects, avoid rainwater entry, and have good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

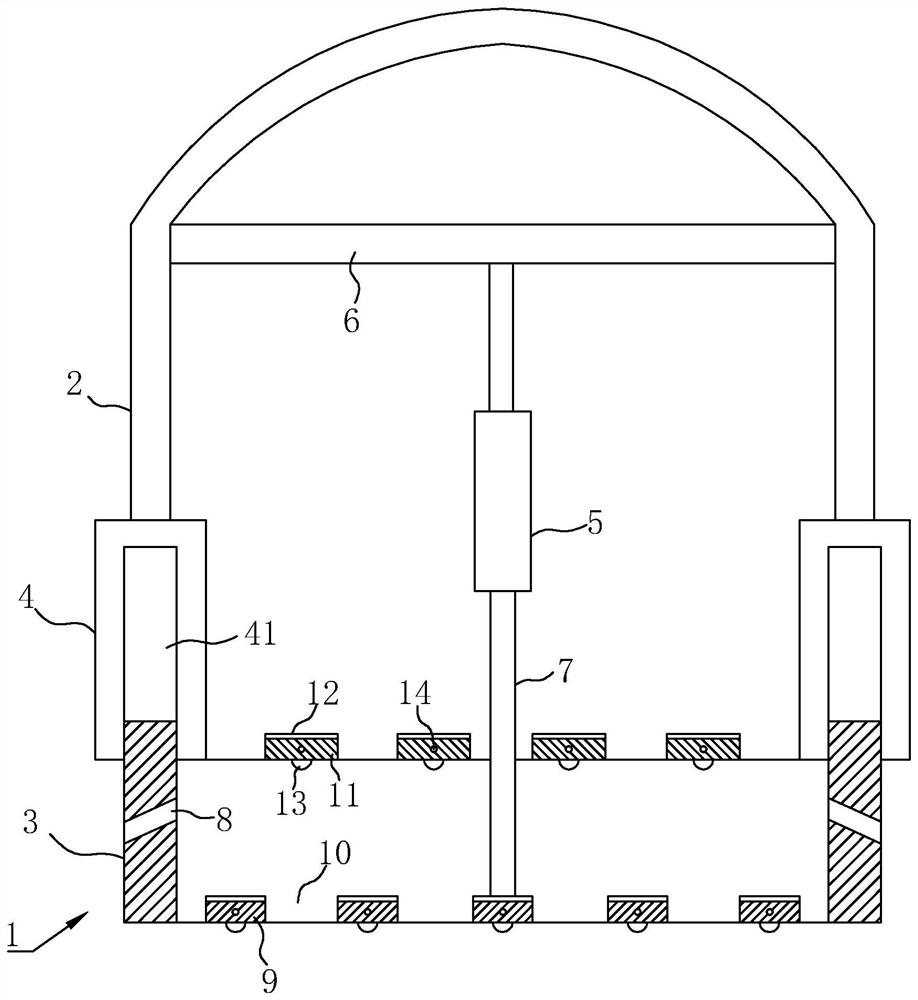

[0034] Embodiment 1: refer to figure 1 , is a daylighting and lighting system for medium and high-rise buildings disclosed by the present invention, comprising a base frame 1 and a skylight 2 located above the base frame 1, the skylight 2 is made of transparent plastic or glass, and is vertically slidably connected to the base frame 1 The underframe 1 includes a vertical first connecting portion 3 extending on both sides, and the first connecting portion 3 is in the shape of a vertical bar; wherein the skylight 2 includes a ceiling and a side plate below, and the bottom of the side plate is fixedly connected with a The second connecting part 4 connected to the first connecting part 3 is U-shaped and the middle part forms a slot 41 for the insertion of the first connecting part 3 and vertical sliding, and is fixed inside the chassis 1 There is a driving member for driving the skylight 2 to slide vertically, the driving member includes a cylinder 5, the cylinder 5 is vertically ...

Embodiment 2

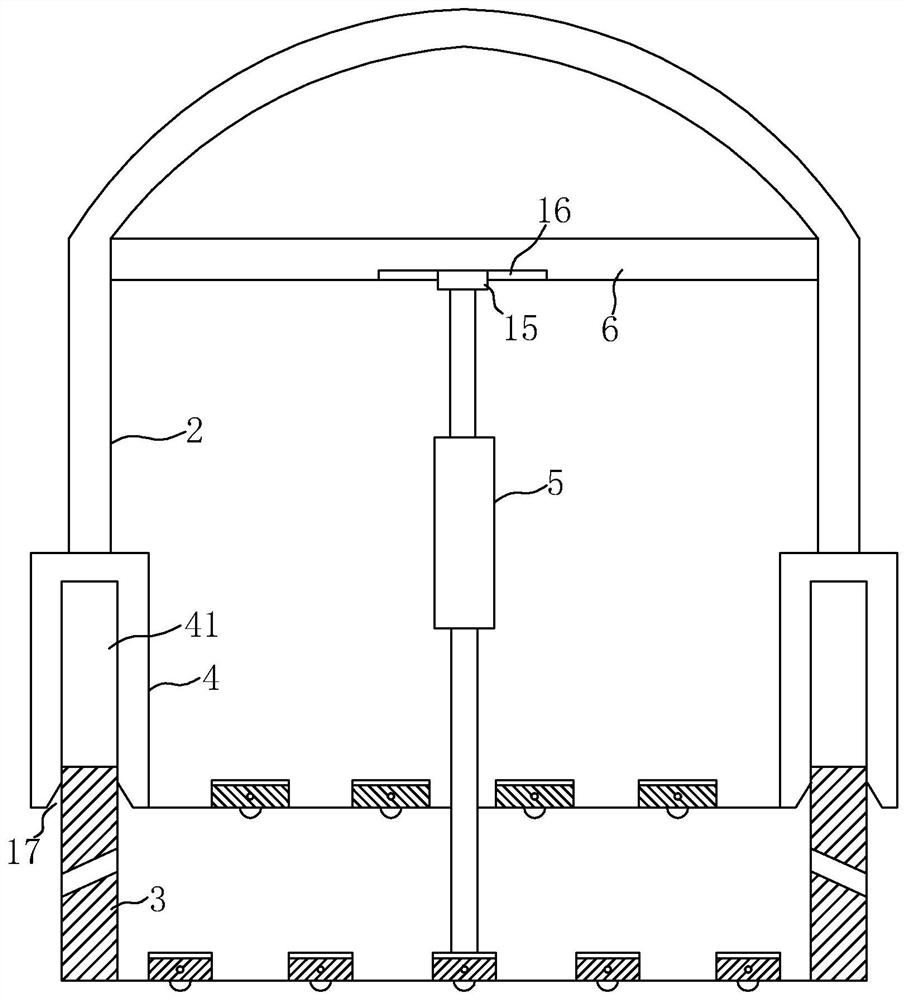

[0039] Embodiment 2: refer to figure 2 , is a daylighting and lighting system for medium and high-rise buildings disclosed by the present invention. The difference between it and Embodiment 1 is that the end of the piston rod of the cylinder 5 is horizontally slidably connected with the cross bar 6, and a slider is fixed on the top of the piston rod of the cylinder 5. 15. At the same time, the bottom wall of the cross bar 6 is provided with a chute 16 that is horizontally slidably connected with the slider 15. The vertical sections of the slider 15 and the chute 16 are T-shaped, so that when the two are slidably connected At the same time, the state of vertical linkage is realized; this can effectively cooperate with the insertion of the slot 41 on the second connection part 4 and the first connection part 3, and avoid the slight deviation between the two, which will cause the two to be stuck and difficult to plug in and fit.

[0040] In addition, the opening 17 of the slot 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com