Mortise structure for floors

A tongue-and-groove and floor technology, applied in the field of tongue-and-groove structures, can solve problems such as harsh noise, relative displacement, and increased contact surface strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

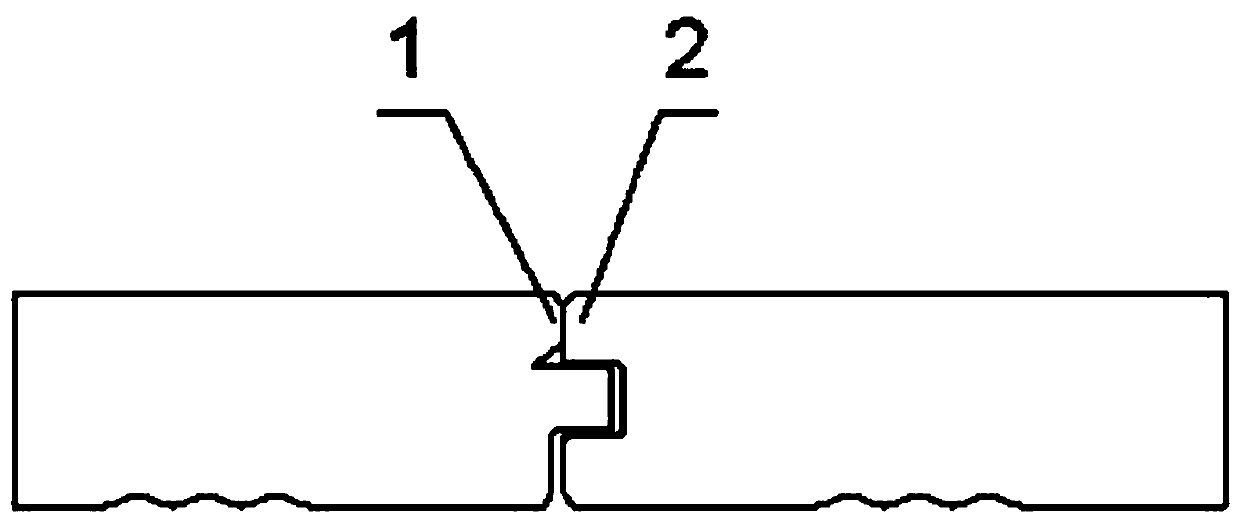

[0009] Embodiments of the present invention: as attached figure 1 As shown, it includes a tenon surface 1 and a groove surface 2 that cooperate with each other, wherein the upper part of the tenon surface 1 is inclined inward by 0.5°, and the upper part of the groove surface 2 is also inclined inward by 0.5°, and the outer side of the tenon surface The end is chamfered at 45°, and the upper contact part of the tenon surface 1 and the groove surface 2 is required to be in surface contact. Form surface contact, which can increase the contact area between the tenon and the groove, reduce the strength of the force on it, and avoid harsh noise when stepping on it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com