Wire and cable defect detection system

A wire and cable and defect detection technology, applied in the field of defect detection, can solve the problems of strong subjectivity, low detection efficiency and accuracy, and high cost, and achieve the effect of improving detection accuracy and automation level, improving effect, and reducing shock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described in conjunction with the following examples.

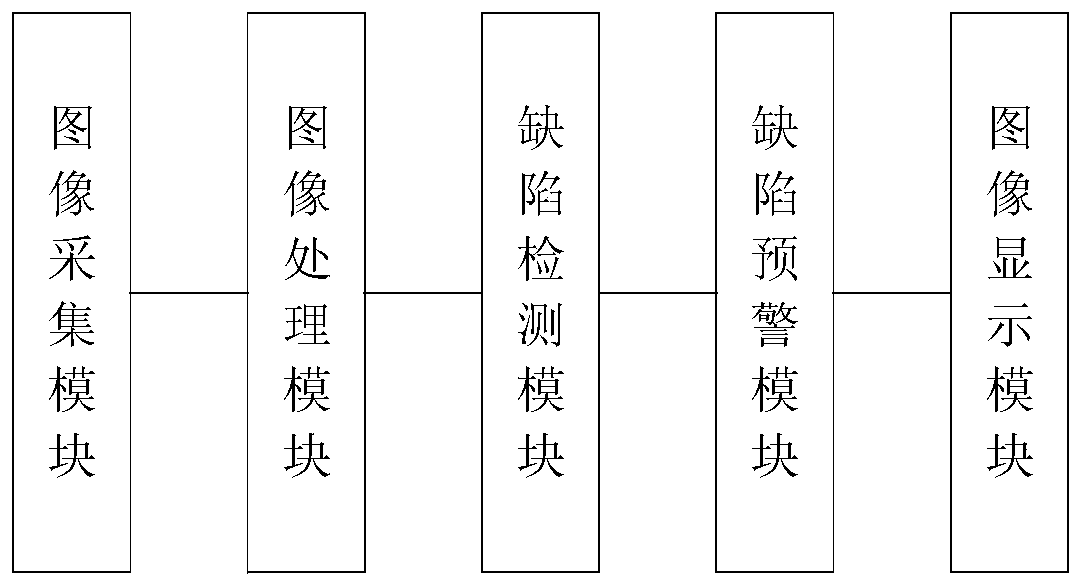

[0029] see figure 1 , a wire and cable defect detection system in this embodiment includes an image acquisition module, an image processing module, a defect detection module, a defect early warning module, and an image display module, and the image acquisition module is used to comprehensively collect the wire and cable to be detected The surface image, the image processing module is used to denoise the collected wire and cable image, and perform target segmentation on the denoised wire and cable image to obtain the wire and cable area image in the wire and cable image, and the defect The detection module is used to calculate the variance of the pixel gray value in the image of the wire and cable area, and compare the calculated variance with a given defect threshold. When the variance is higher than the given defect threshold, it is determined that the If there is a defect on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com