Servo driving system and method based on wireless communication

A wireless communication, servo-driven technology, applied in signal transmission system, control system, motor control, etc., can solve the problems of complex debugging work of the drive system, complex routine maintenance work, complex robot structure design, cumbersome disassembly and installation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

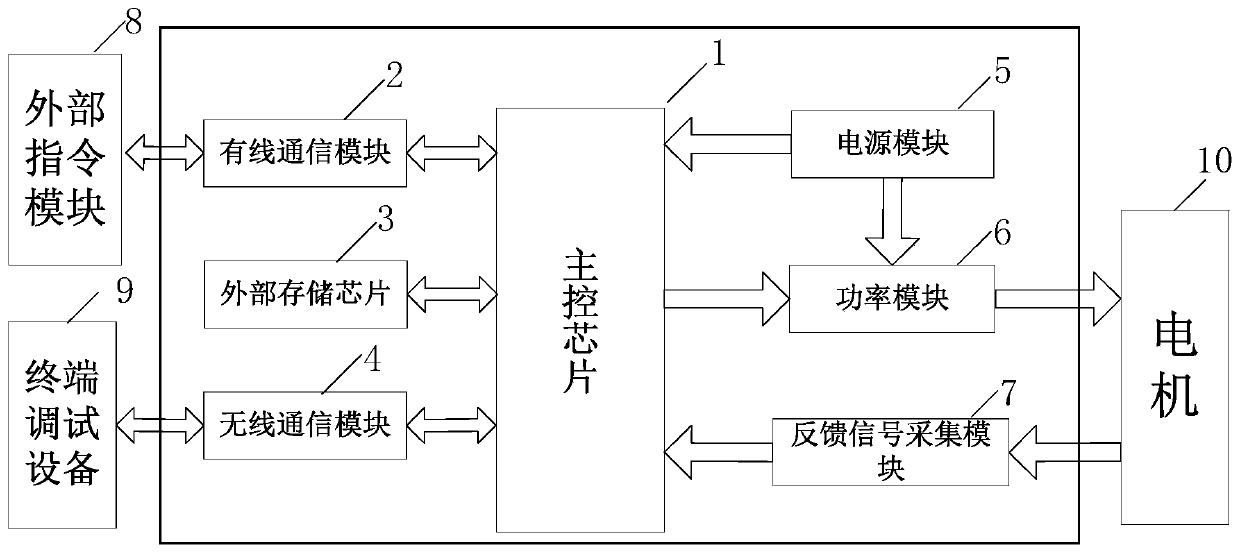

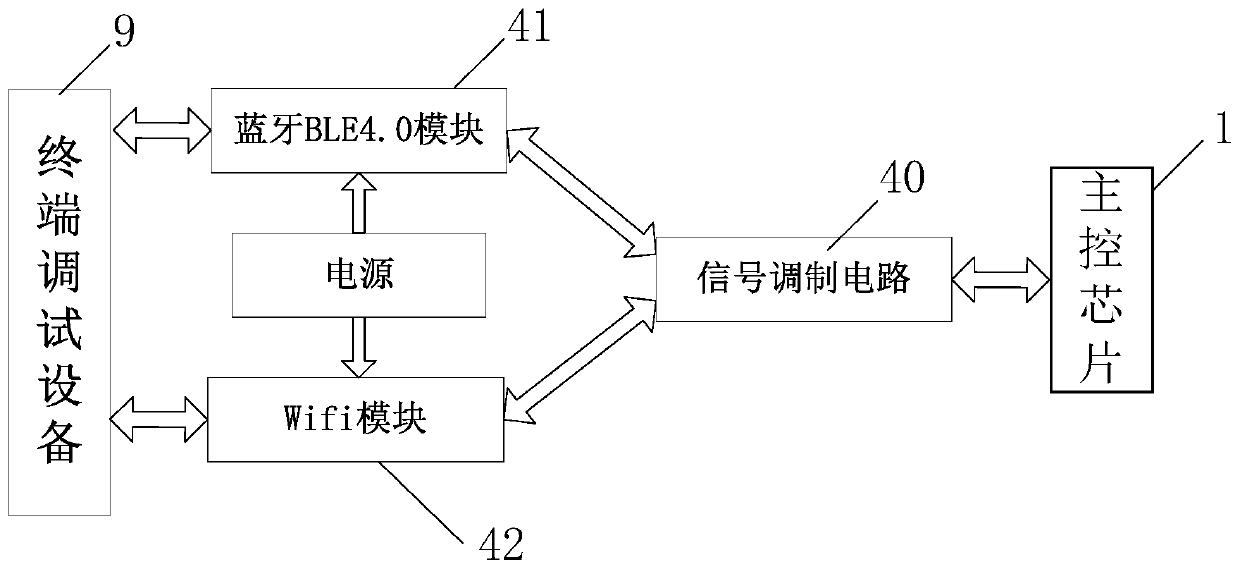

[0019] The invention discloses a servo drive system based on wireless communication, which combines figure 1 and figure 2 As shown, it includes a main control chip 1, a power module 6, a motor 10, a wireless communication module 4 and a terminal debugging device 9, wherein:

[0020] The power module 6 is connected between the main control chip 1 and the motor 10, the main control chip 1 is used to send a control command to the power module 6, and the power module 6 drives according to the control command The motor 10 runs;

[0021] The wireless communication module 4 is connected to the main control chip 1, the terminal debugging device 9 establishes wireless communication with the wireless communication module 4, and the wireless communication module 4 enables the terminal debugging device 9 to The main control chip 1 performs data debugging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com