Transfer trolley for logistics storage

A warehousing and logistics technology, applied in the field of materials, can solve problems such as poor safety and ineffective fixing of items, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

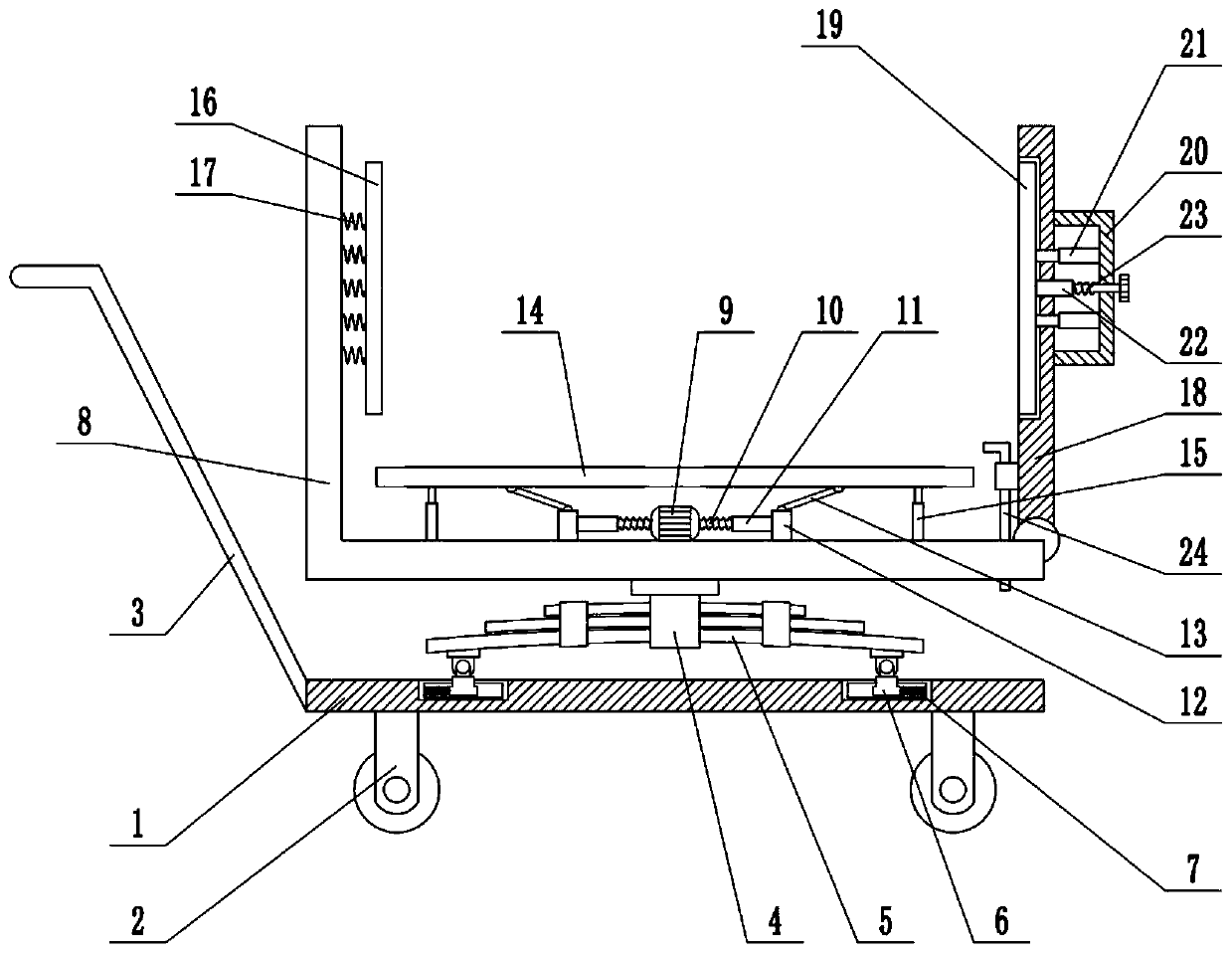

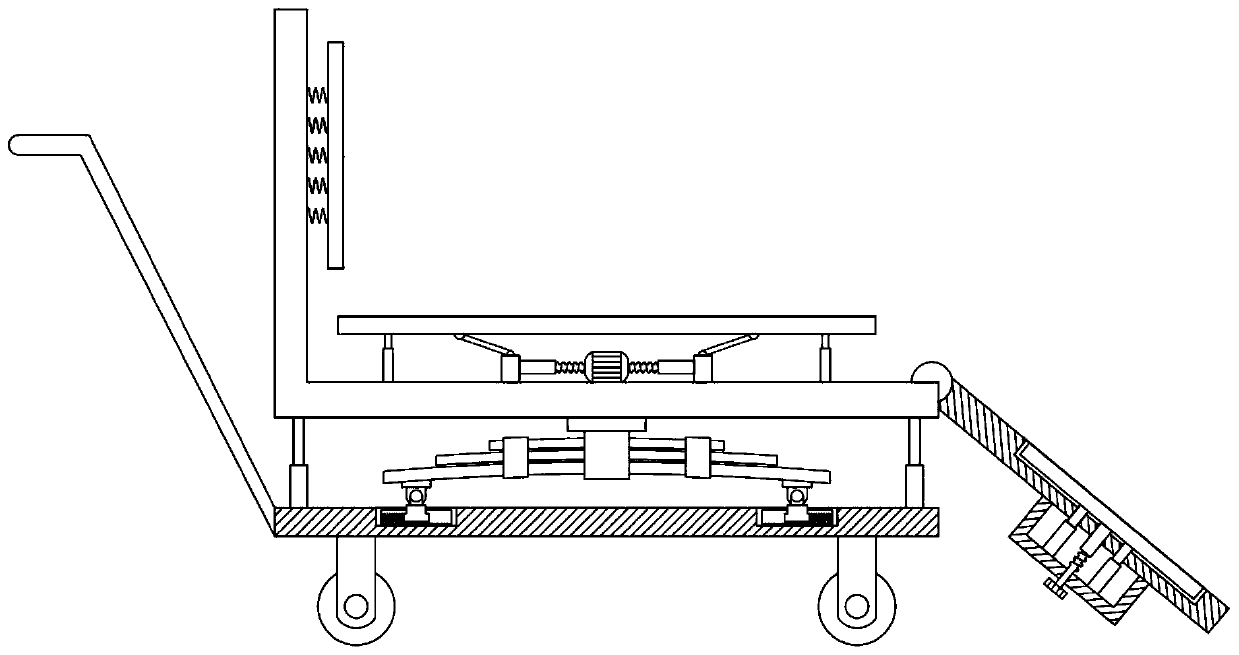

Embodiment 1

[0022] see Figure 1-3 , in an embodiment of the present invention, a transfer trolley for logistics storage includes a vehicle frame 1, a universal wheel 2, a push rod 3 and a vehicle body 8, the bottom of the vehicle frame 1 is equipped with a universal wheel 2, and the left end of the vehicle frame 1 is installed Push rod 3 is arranged, is convenient to promote this device mobile position, and the top of vehicle frame 1 is provided with vehicle body 8, and the lower surface of vehicle body 8 is fixedly connected with fixed frame 4, and leaf spring 5 is installed on the fixed frame 4, and the bottom of leaf spring 5 two A damping block 6 is installed at the end, and a chute is provided on the upper surface of the vehicle frame 1. The damping block 6 is embedded in the chute, and a damping spring 7 is installed on the inner wall of the chute. The shock block 6 is connected, the left side wall of the vehicle body 8 is equipped with a buffer plate 16, the buffer plate 16 is dis...

Embodiment 2

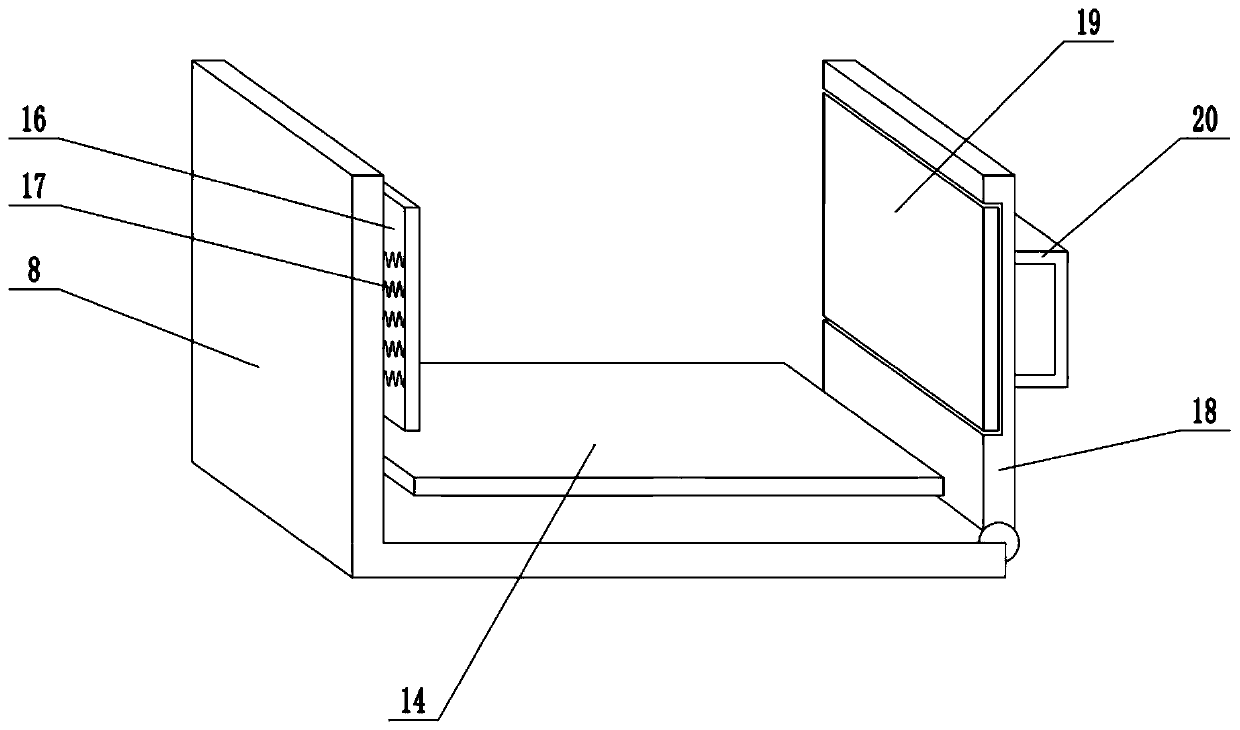

[0024] On the basis of Embodiment 1, the upper surface of the vehicle body 8 is fixedly connected with a biaxial motor 9, and the left and right shaft extension ends of the biaxial motor 9 are fixedly connected with an adjusting screw 10, and the end of the adjusting screw 10 is sleeved with a The adjusting sleeve 11, the biaxial motor 9 is threadedly connected with the adjusting screw rod 10, the biaxial motor 9 is a forward and reverse motor, the end of the adjusting sleeve 11 is fixedly connected with a slider 12, and the slider 12 is connected to the upper surface of the vehicle body 8 The sliding connection controls the forward and reverse rotation of the double-axis motor 9, which can drive the adjustment screw 10 to move forward and reverse, thereby driving the two sliders 12 to move toward each other or move backwards. A lifting plate 14 is provided above the double-axis motor 9 to lift The lower surface of the plate 14 is equipped with a first telescopic rod 15, the lo...

Embodiment 1、 Embodiment 2

[0025] In conjunction with Embodiment 1 and Embodiment 2, the working principle of the present invention is: when the article to be transferred needs to be carried in the vehicle body 8, the pin 24 is extracted, and the movable plate 18 can rotate freely, so that the movable plate 18 is inclined at the bottom right, and at the same time Control the forward and reverse rotation of the double-axis motor 9, and drive the two sliders 12 to move toward each other or move backwards. When the two sliders 12 move toward each other, the connecting rod 13 is driven to rotate in the horizontal direction, thereby driving the lifting plate 14 downward. Move, when the two sliders 12 move backwards, it will drive the connecting rod 13 to rotate vertically, thereby driving the lifting plate 14 to move upwards to achieve the effect of adjusting the height of the lifting plate 14, which is convenient for people to adjust the lifting plate according to actual needs The height of 14 is convenient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com