Multi-group hydraulic linkage lifting mechanism

A lifting mechanism and hydraulic linkage technology, which is applied in the direction of lifting frame and lifting device, can solve the problems of deep installation pit of the lift, small lifting range, and inconvenient maintenance of the lift, so as to improve the lifting effect and install And the effect of easy maintenance and high market application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

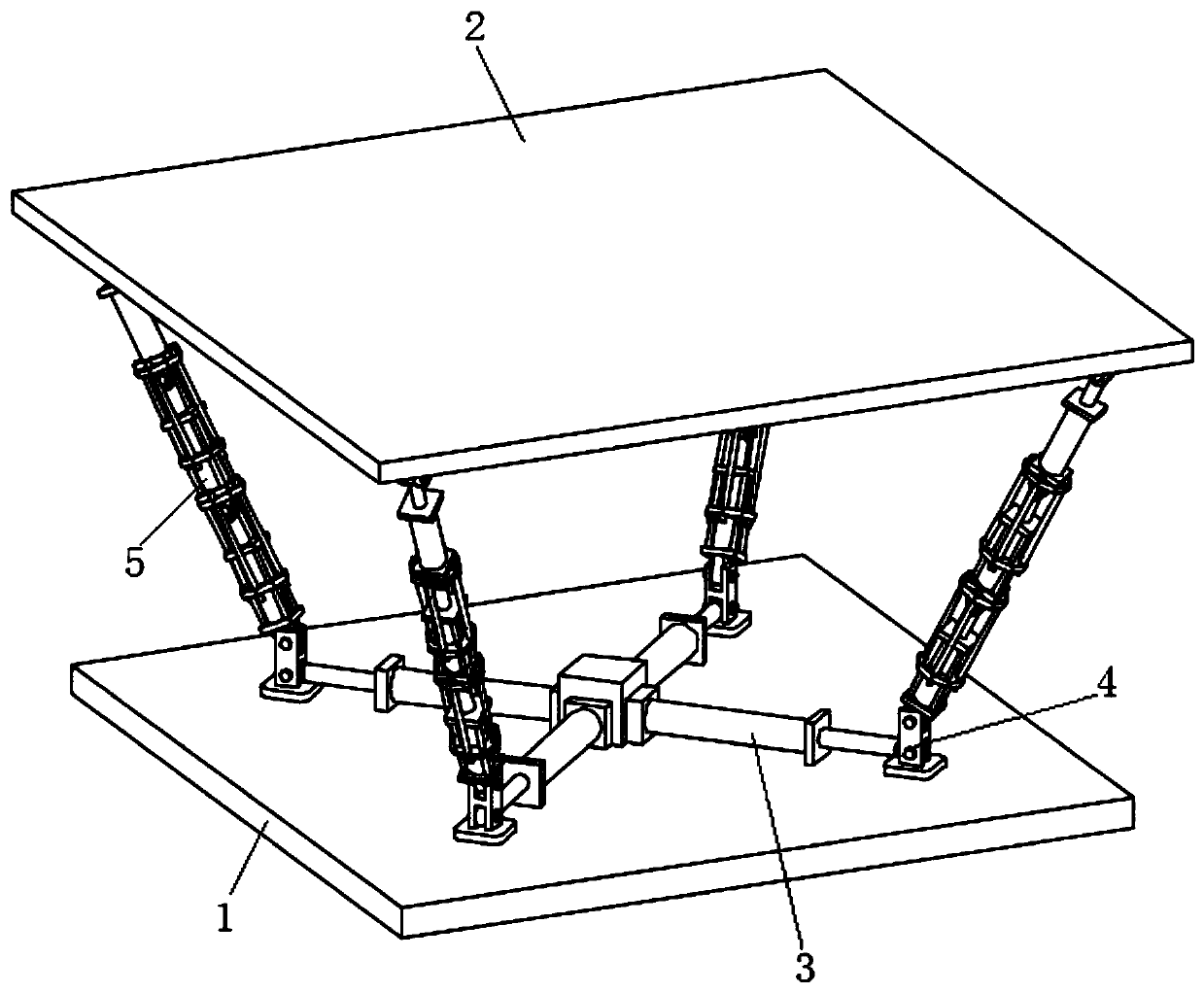

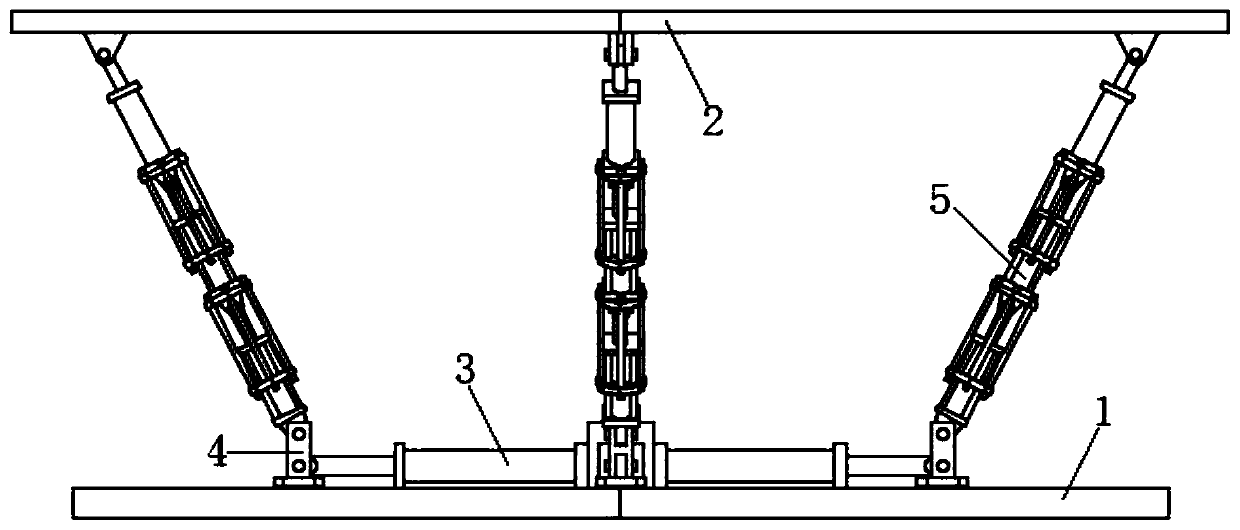

[0026] see Figure 1-5 As shown, the present invention is a multi-group hydraulic linkage lifting mechanism, including a base 1 and a lifting platform 2 arranged in parallel; the base 1 is arranged below the lifting platform 2; the upper surface of the base 1 is symmetrically fixed. There are four horizontal hydraulic telescopic parts 3; the horizontal hydraulic telescopic parts 3 include a horizontal hydraulic cylinder; the four horizontal hydraulic telescopic parts 3 are arranged in a "ten" shape; the output end of the horizontal hydraulic telescopic parts 3 is equipped with a guide The bearing block 4; the upper part of the guide bearing block 4 is rotatably equipped with an inclined hydraulic telescopic part 5;

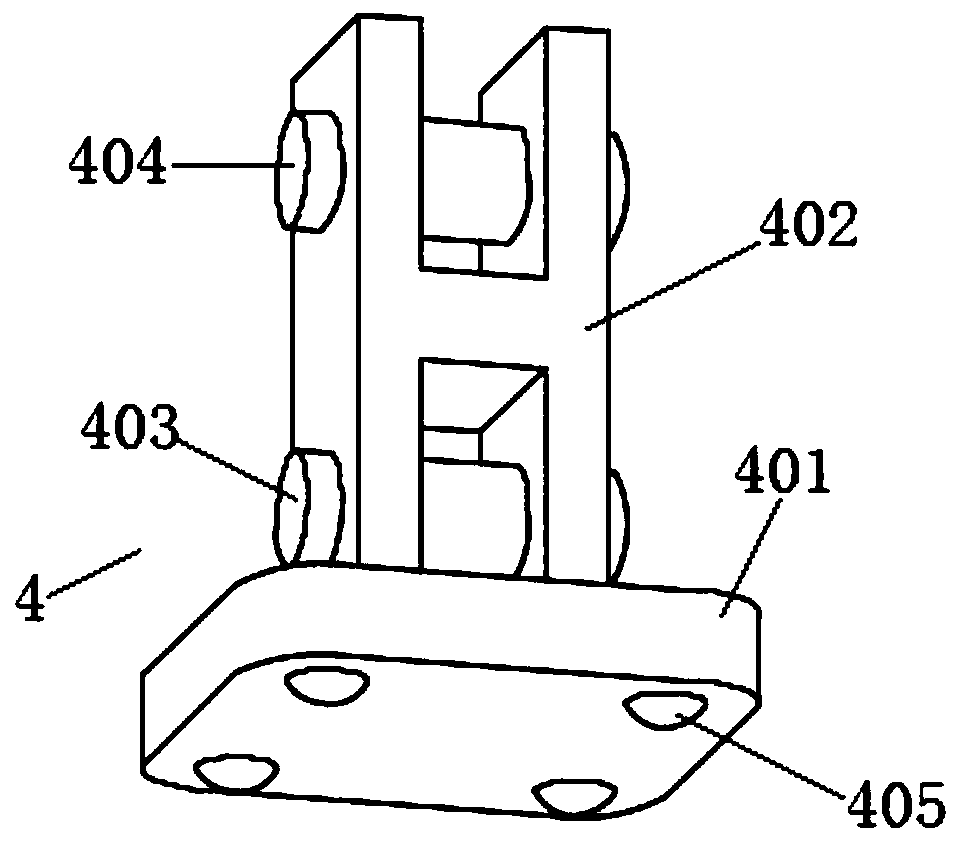

[0027] Among them such as Figure 2-3 As shown, the guide bearing block 4 is slidably installed on the upper surface of the abutment 1; the guide bearing block 4 includes a bearing plate 401 and a support block 402 in an H-shaped structure; the support block 402 ...

specific Embodiment 2

[0030] The horizontal hydraulic telescopic part 3 includes a plurality of horizontal hydraulic cylinders; a plurality of horizontal hydraulic cylinders are coaxially arranged, and a plurality of horizontal hydraulic cylinders are connected end to end in turn; that is, the output end of one horizontal hydraulic cylinder is connected to another On the end of the cylinder body of the horizontal hydraulic cylinder; other structures are identical to the technical scheme in the specific embodiment one.

specific Embodiment 3

[0032] A mounting block is arranged between the four horizontal hydraulic telescopic parts 3; the mounting block is fixed on the upper surface of the base 1; the upper surface of the mounting block is vertically equipped with a guiding support member for ensuring the lifting platform 2 to move up and down smoothly The guiding support component is a vertical hydraulic cylinder or other mechanisms capable of guiding work; the output end of the vertical hydraulic cylinder is fixed on the lower surface of the lifting platform 2; other structures are the same as the technical solution in the first embodiment.

[0033] For the layout between the hydraulic cylinders of multiple groups of hydraulic linkage lifting mechanisms, in Figure 1-5 In the technical scheme of the present invention, the horizontal hydraulic telescopic part 3 is arranged on the inner side of the inclined hydraulic telescopic part 5, and the included angle between the hydraulic telescopic part 3 and the inclined h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com